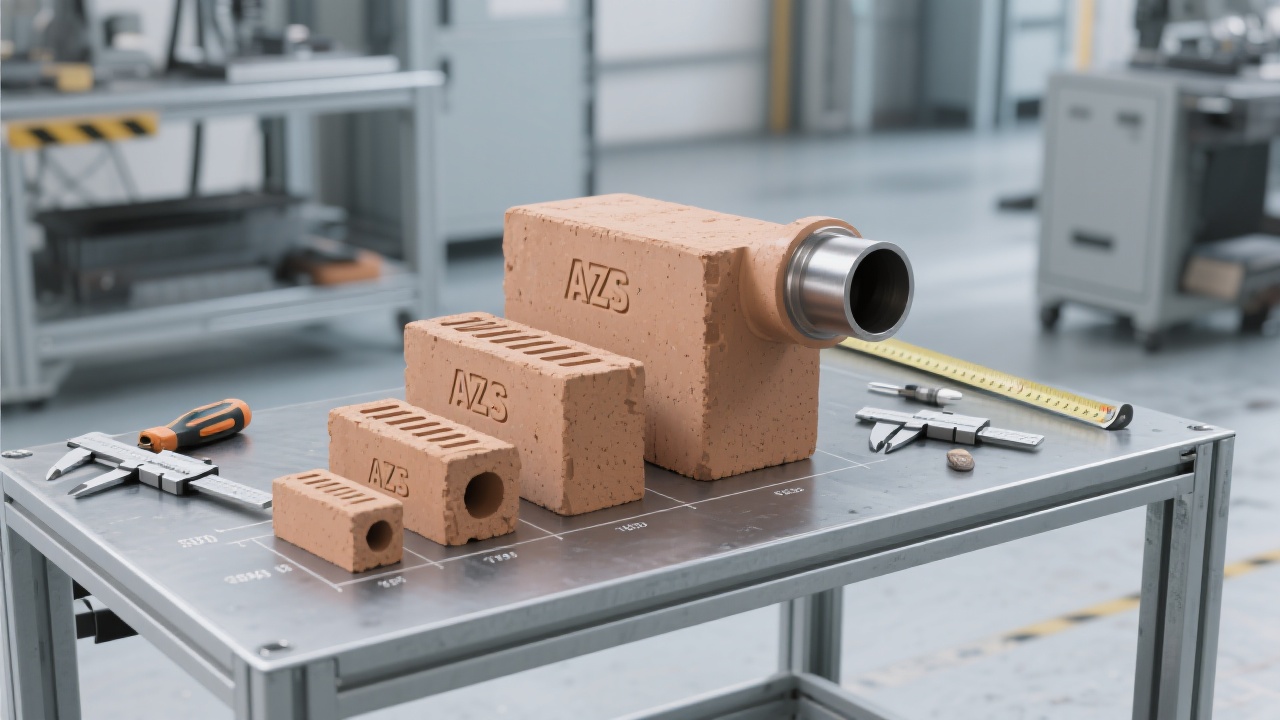

Fused AZS (Alumina-Zirconia-Silica) cast blocks remain a cornerstone in refractory solutions within the glass manufacturing industry. Their unique microstructure and composition deliver exceptional wear resistance, thermal shock durability, and high-temperature corrosion protection, which are crucial for the harsh environment inside glass melting furnaces. This article explores the scientific principles underlying fused AZS blocks, highlights real-world customer applications in glass furnace sidewalls and charging channels, and offers key guidelines for installation and maintenance to maximize operational uptime and reduce costs.

Fused AZS cast blocks typically comprise a balanced mixture of approximately 45-50% alumina (Al2O3), 30-35% zirconia (ZrO2), and 15-20% silica (SiO2). This precise ratio promotes the formation of a densely packed crystalline matrix, which ensures limited porosity and strong chemical bonding among phases, enhancing thermal stability and mechanical strength.

The presence of zirconia acts as a key phase for toughening through its tetragonal phase transformation toughening mechanism, which resists crack propagation under thermal shock. The alumina contributes to hardness and abrasion resistance, while silica serves as the glass-forming component that facilitates structural integrity at elevated temperatures around 1400–1600°C.

Table 1: Typical Fused AZS Block Composition and Properties

| Component | Content (wt %) | Key Function |

|---|---|---|

| Alumina (Al2O3) | 45 - 50 | Hardness, Abrasion Resistance |

| Zirconia (ZrO2) | 30 - 35 | Thermal Shock Toughening |

| Silica (SiO2) | 15 - 20 | Structural Integrity at High Temperatures |

The extreme conditions within glass melting furnaces—temperatures often exceeding 1500°C, aggressive molten glass contact, and frequent thermal cycling—require refractory materials with unmatched reliability. Fused AZS blocks display some of the highest abrasion resistance indexes in the industry, with wear rates reported below 0.03 mm/week in typical glass furnace sidewall applications.

Moreover, the material’s superior thermal shock resistance means it can endure repeated heating and cooling cycles without catastrophic cracking, reducing downtime caused by block replacement. Its excellent corrosion resistance minimizes dissolution by molten glass, offering stable dimensional integrity and extending service life significantly compared with conventional refractories.

Several leading glass factories have adopted fused AZS cast blocks specifically in sidewalls and charging channels of their melting furnaces, benefiting from prolonged equipment lifespan and decreased operational disruptions. For example, a glass manufacturer in Central Europe reported extending furnace sidewall block replacement cycles from 12 to over 20 months after switching to premium fused AZS materials, achieving a 30% reduction in maintenance downtime.

In another case, an Asian float glass plant observed a 25% decrease in thermal shock-related failures on charging channels over one year, attributable to the enhanced toughness of fused AZS blocks. These improvements translated to substantial cost savings—both from reduced refractory consumption and more consistent furnace productivity.

Proper installation is critical to leverage the full potential of fused AZS blocks. Manufacturers recommend pre-heating schedules that gradually increase temperature to avoid thermal shock during commissioning. Mechanical fixing through interlocking designs or refractory anchors ensures stability under intense thermal and mechanical stress.

Routine inspections focusing on any early signs of spalling, cracking, or corrosion are essential. Quick repairs of minor damage prevent larger-scale failures and costly furnace outages. Additionally, keeping detailed maintenance records helps correlate furnace performance with refractory conditions and optimize future material selection.

Investing upfront in higher-grade fused AZS cast blocks, paired with scientific maintenance approaches, gives companies a measurable competitive edge by maximizing furnace availability and overall operational efficiency.

Discover how fused AZS cast blocks can revolutionize your furnace lifespan and cost efficiency — Explore Customized Refractory Solutions Today