AZS (Alumina-Zirconia-Silica) channel blocks have emerged as a critical solution for high-temperature applications in industries such as glass manufacturing, metallurgy, and ceramics. These specialized refractory products are designed to withstand extreme heat while maintaining structural integrity and chemical resistance.

Compared to traditional refractory materials like fireclay or silicon carbide, AZS channel blocks offer superior thermal shock resistance and lower porosity. This makes them ideal for environments where temperatures can exceed 1600°C. The unique composition of AZS ensures minimal expansion and excellent corrosion resistance against molten glass and metal slags.

| Material Type | Max Temperature (°C) | Porosity (%) | Thermal Shock Resistance |

|---|---|---|---|

| Fireclay | 1400 | 20–25 | Low |

| Silicon Carbide | 1700 | 5–10 | Medium |

| AZS Channel Blocks | 1750+ | 2–5 | High |

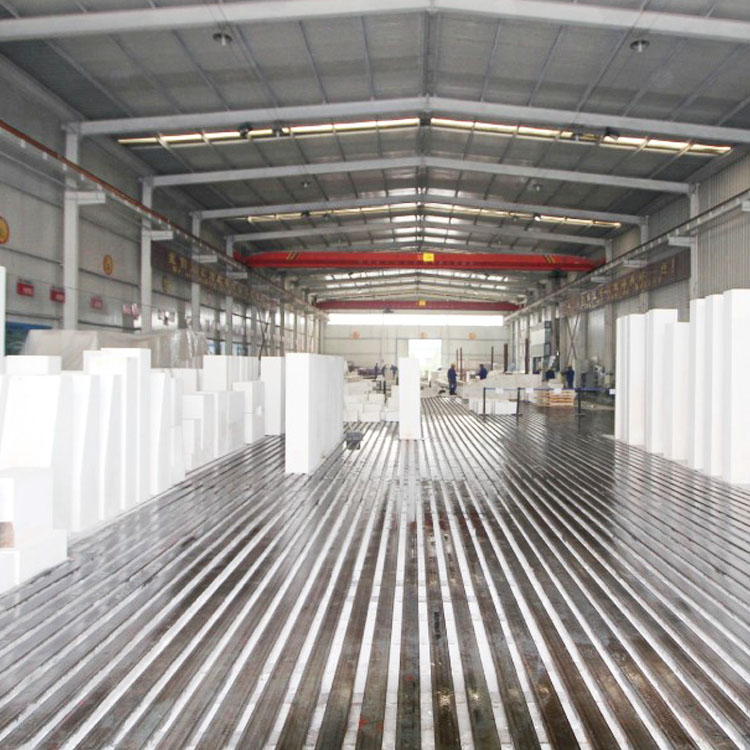

The production of AZS channel blocks begins with the fusion of high-purity raw materials—aluminum oxide, zirconium oxide, and silica—using an electric furnace. The molten mixture is then cast into molds and allowed to solidify under controlled conditions. This process results in a dense, ceramic-bonded structure that enhances mechanical strength and thermal stability.

Each batch undergoes rigorous quality control checks, including chemical analysis, density measurement, and thermal cycling tests. This ensures that every AZS channel block meets international standards and performs reliably in demanding environments.

AZS channel blocks are certified under ISO 9001, ensuring compliance with global quality management standards. This certification guarantees consistent product performance, traceability, and customer satisfaction. It also provides confidence to buyers that the material has been produced through a reliable and controlled process.

Several leading manufacturers have adopted AZS channel blocks and reported significant improvements in operational efficiency and equipment lifespan. For example, a major glass producer in Europe saw a 30% reduction in refractory wear after switching to AZS channel blocks. Another case involved a steel plant in Asia, where AZS blocks extended the service life of their melting furnaces by over 20%.

With its exceptional performance, advanced manufacturing, and ISO-certified quality, AZS channel blocks are the ideal choice for high-temperature applications. Whether you're looking to improve efficiency, reduce maintenance costs, or enhance product quality, our AZS solutions are designed to meet your needs.

Don't miss out on the opportunity to elevate your operations. Contact us today to learn more about our AZS channel blocks and how they can benefit your business.

Get In Touch Now