In the glass industry, the choice of refractory materials is crucial for ensuring stable production and high - quality products. AZS nozzle blocks, as high - performance refractory materials, have unique advantages that can effectively address the challenges in glass production.

One of the most prominent features of AZS nozzle blocks is their high refractoriness and excellent thermal stability. In the high - temperature environment of glass production, where temperatures can reach up to 1500 - 1600°C, AZS nozzle blocks can maintain their structural integrity. For example, compared with ordinary refractory materials, the deformation rate of AZS nozzle blocks at 1550°C is less than 1%, while that of ordinary refractory materials can reach 5 - 10%. This data clearly shows the superiority of AZS nozzle blocks in high - temperature resistance.

"The high refractoriness of AZS nozzle blocks is like a shield in the high - temperature battlefield of glass production, protecting the production process from the impact of high - temperature damage," said an industry expert.

Glass production involves various corrosive substances, such as molten glass and fluxes. AZS nozzle blocks have excellent anti - corrosion and anti - erosion properties. They can resist the corrosion of molten glass and fluxes, effectively reducing the wear and tear of the nozzle blocks. In a glass production line, after using AZS nozzle blocks, the corrosion rate of the nozzle blocks is reduced by 60% compared with traditional materials. This not only extends the service life of the nozzle blocks but also significantly reduces the production of defective products. The defect rate of glass products has dropped from 8% to 2%.

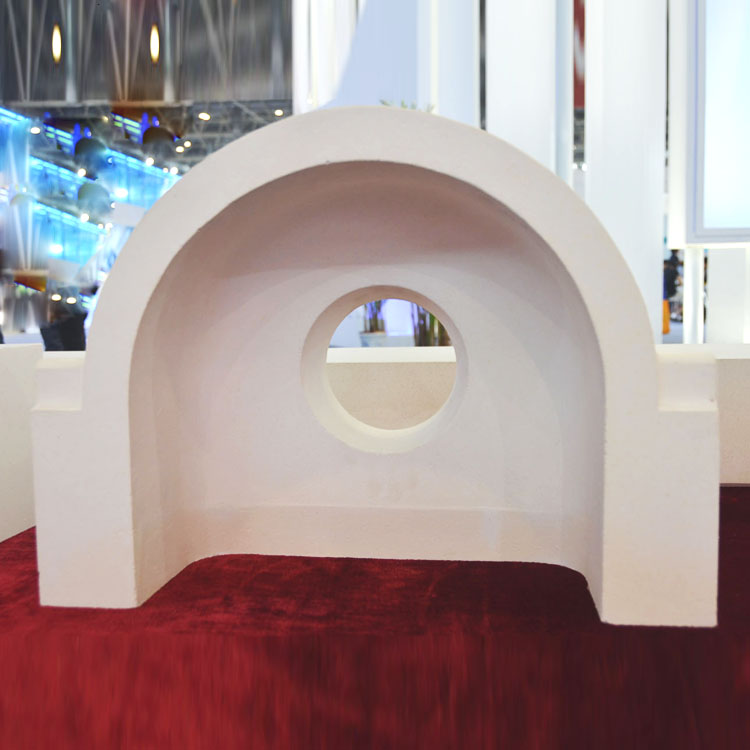

Each glass production enterprise has different production processes and requirements. The customized production service of AZS nozzle blocks can fully meet these diverse needs. A glass enterprise in Europe needed a special - shaped AZS nozzle block for its new production line. Through the customized service, the enterprise obtained the perfect - fitting nozzle block within a short time. This customized nozzle block improved the production efficiency of the enterprise by 30% and reduced the energy consumption by 15%.

AZS nozzle blocks are widely used in various glass production scenarios, such as float glass production, container glass production, and optical glass production. In the float glass production process, AZS nozzle blocks ensure the uniform flow of molten glass, improving the flatness and transparency of the glass. In container glass production, they help to maintain the stability of the glass - forming process, reducing the occurrence of bubbles and impurities.

For customers, the use of AZS nozzle blocks means long - term value. They can reduce production costs, improve product quality, and enhance market competitiveness. A glass enterprise in Asia has been using AZS nozzle blocks for 5 years. During this period, the enterprise has saved approximately $500,000 in production costs and increased its market share by 10% due to the improved product quality.

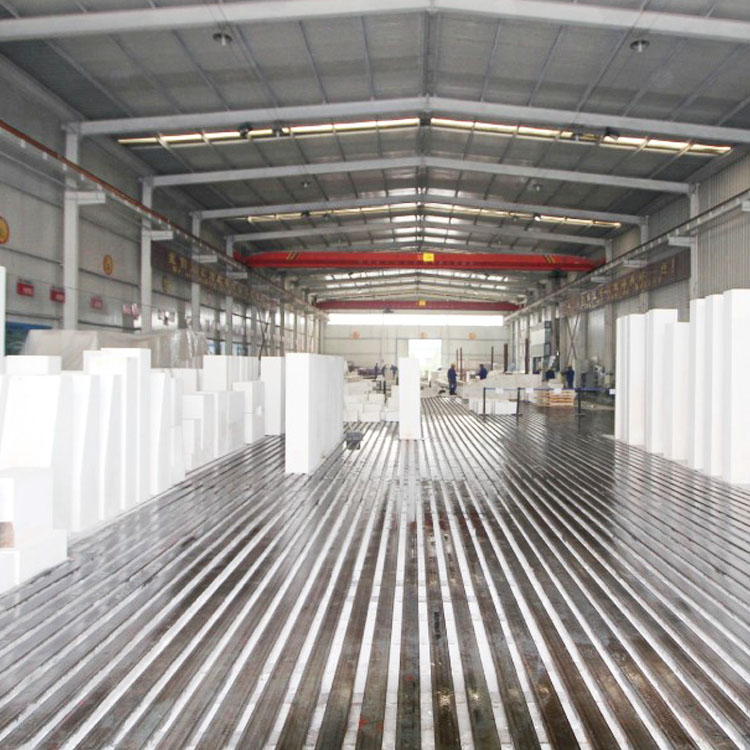

AZS nozzle blocks, with their outstanding technical advantages, anti - corrosion properties, and customized production services, are ideal choices for glass enterprises. They can bring stable production, high - quality products, and long - term economic benefits to customers. If you are looking for a reliable refractory material solution for your glass production, don't miss the opportunity to choose AZS nozzle blocks. Click here to learn more about how AZS nozzle blocks can enhance your industry competitiveness!

.jpg)

Do you have similar problems in your glass production? Share your specific scenarios with us, and we'll send you 3 solution cases from the same industry.