High-temperature industrial kilns are the backbone of many manufacturing industries, from glass production to metal smelting. The lining of these kilns plays a crucial role in ensuring their efficient operation and longevity. However, lining failure is a common problem that can lead to increased maintenance costs, reduced productivity, and even safety hazards. In this article, we will explore the common issues of high-temperature industrial kiln lining failure and provide five material strategies to enhance equipment lifespan.

The performance of high-temperature industrial kiln lining materials is determined by several key factors, including chemical composition, bulk density, porosity, thermal shock resistance, and corrosion resistance. Let's take a closer look at each of these factors:

The chemical composition of lining materials has a significant impact on their performance. For example, the content of alumina (Al₂O₃) and zirconia (ZrO₂) in fused AZS bricks can affect their refractoriness and corrosion resistance. In general, a higher content of these oxides indicates better performance. According to industry data, fused AZS bricks with an alumina content of 36% (such as TY - AZS36) have excellent corrosion resistance in glass melting furnaces.

Bulk density is an important indicator of the compactness of lining materials. Higher bulk density usually means better mechanical strength and lower porosity. Porosity, on the other hand, affects the permeability of gases and liquids, which in turn affects the corrosion resistance of the materials. Studies have shown that lining materials with a porosity of less than 10% have better corrosion resistance and thermal shock resistance.

Thermal shock resistance is the ability of lining materials to withstand rapid temperature changes without cracking or spalling. This property is crucial in high - temperature industrial kilns, where the temperature can fluctuate significantly during operation. The microstructure of the materials plays a key role in their thermal shock resistance. For example, materials with a fine - grained and homogeneous microstructure tend to have better thermal shock resistance. Research has found that fused AZS bricks can withstand temperature changes of up to 500°C without significant damage.

Corrosion resistance is another important performance indicator of lining materials. In high - temperature industrial kilns, the lining materials are exposed to various corrosive substances, such as molten glass, slag, and gases. The chemical composition and microstructure of the materials determine their corrosion resistance. Fused AZS bricks, especially the TY - AZS36 type, have excellent corrosion resistance due to their unique chemical composition and dense microstructure.

To understand the thermal shock and corrosion resistance of lining materials, it is necessary to study their microstructure. Microstructure analysis shows that the distribution of crystals, grains, and pores in the materials affects their performance. For example, the presence of fine - grained crystals can improve the thermal shock resistance by absorbing and dissipating thermal stress. In terms of corrosion resistance, a dense and homogeneous microstructure can prevent the penetration of corrosive substances.

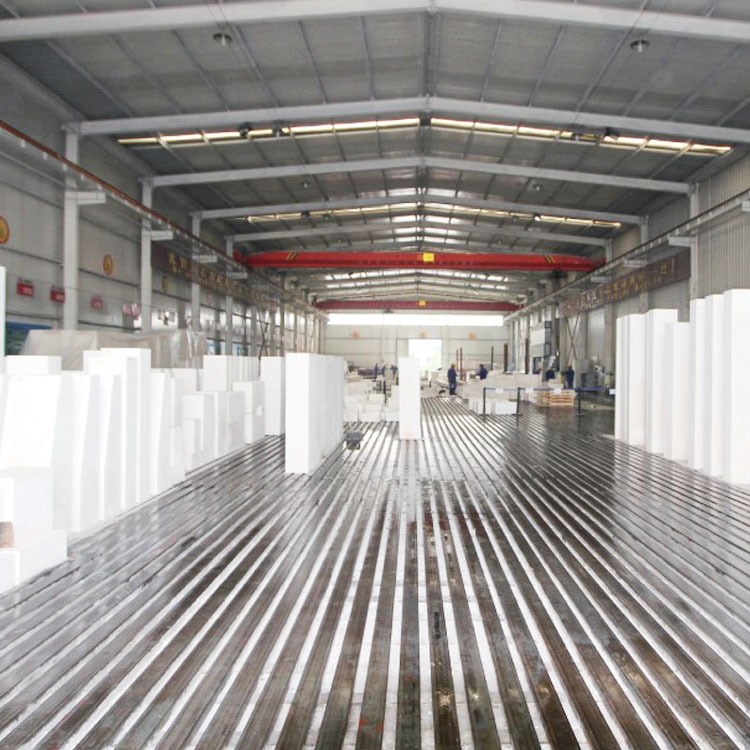

Let's take a typical glass melting furnace as an example to illustrate the material selection logic and optimization path. In a glass melting furnace, the lining materials are exposed to high - temperature molten glass and corrosive gases. Therefore, materials with high refractoriness, good thermal shock resistance, and excellent corrosion resistance are required. Fused AZS bricks, such as TY - AZS36, are often the preferred choice due to their outstanding performance.

When selecting lining materials, it is necessary to consider the specific operating conditions of the kiln, such as temperature, pressure, and the type of corrosive substances. By analyzing these factors, engineers and procurement decision - makers can choose the most suitable materials to improve the lifespan and operating efficiency of the equipment.

The high - temperature industrial kiln lining industry faces several pain points, such as insufficient corrosion resistance and thermal shock damage. To address these issues, we propose the following practical material selection and maintenance strategies:

If you are an engineer or a procurement decision - maker in the high - temperature industrial kiln industry, you may be interested in learning more about the performance advantages and application value of fused AZS bricks TY - AZS36. These bricks can effectively solve the lining failure problems of high - temperature industrial kilns and improve the lifespan and operating efficiency of your equipment. To learn more, please visit CTA - URL.