In the high-temperature industrial kiln lining material selection process, the chemical composition directly affects the performance of the corrosion resistance rate. This article, through actual measurement and comparison of the corrosion resistance performance of different AZS bricks, delves into the influence mechanism of key elements such as Al₂O₃, ZrO₂, and SiO₂ on the high-temperature corrosion resistance ability. It reveals why the fused AZS brick TY - AZS36 has become the ideal choice for high - risk areas such as the side walls and throats of glass melting furnaces.

Let's first understand the relationship between the core performance indicators of high - temperature kiln lining materials and their chemical composition. Core performance indicators include bulk density, porosity, and thermal shock resistance. For example, a higher bulk density usually means a more compact structure, which can enhance the material's ability to resist external forces and corrosion. The porosity is also crucial. A lower porosity indicates fewer channels for corrosive substances to penetrate, thus improving the corrosion resistance. Generally, high - quality high - temperature kiln lining materials have a bulk density of around 3.5 - 3.8 g/cm³ and a porosity of ≤1.0%.

Through experimental data comparison, we can clearly see the differences in the corrosion resistance rates of different AZS bricks. The fused AZS brick TY - AZS36 shows significant advantages. In a series of tests, its high - temperature corrosion resistance rate is ≤1.3mm/24h, which is much lower than many other similar products in the market. This excellent performance is mainly due to its unique chemical composition and microstructure.

From a microscopic perspective, the dense structure of the fused AZS brick TY - AZS36 can effectively reduce the precipitation of the glass phase and resist corrosion. The glass phase precipitation temperature of TY - AZS36 is ≥1400℃. When the temperature is lower than this value, the glass phase is less likely to precipitate, which means less corrosion risk. The following table shows the comparison of the corrosion resistance rates of different AZS bricks:

| AZS Brick Type | Corrosion Resistance Rate (mm/24h) |

|---|---|

| TY - AZS36 | ≤1.3 |

| Common AZS Brick 1 | 2.0 - 2.5 |

| Common AZS Brick 2 | 2.5 - 3.0 |

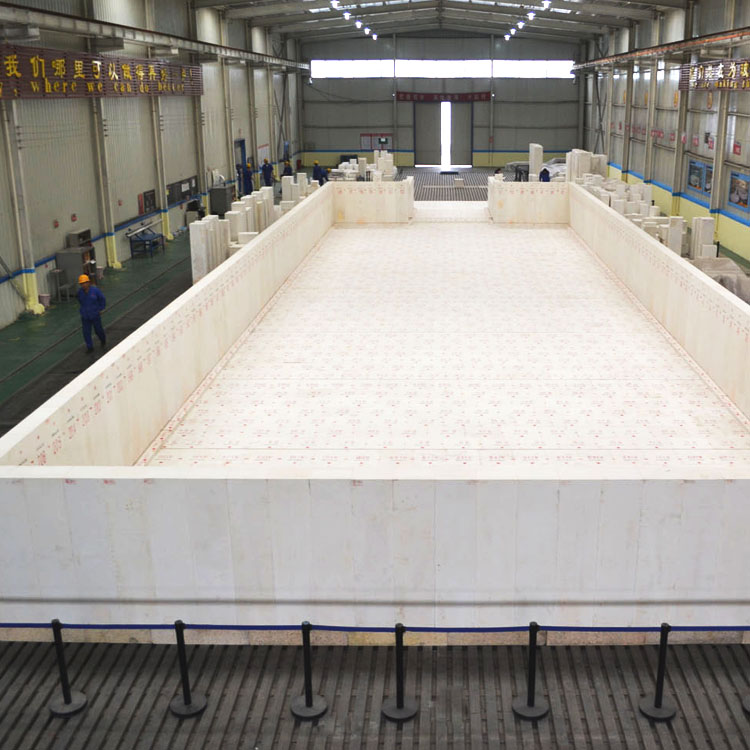

Let's look at some typical application cases in glass melting furnaces. In a large - scale glass manufacturing plant, after replacing the original lining materials with the fused AZS brick TY - AZS36 in the side walls and throats of the glass melting furnace, the stability of the equipment has been significantly improved. The maintenance cycle has been extended from the original 6 - 8 months to 12 - 15 months, which greatly reduces the production interruption time and maintenance costs.

Based on different working conditions, we can provide corresponding material selection suggestions. For high - temperature areas with a temperature range of 1400 - 1600℃ and strong corrosion intensity, the fused AZS brick TY - AZS36 is an ideal choice. In areas with relatively lower temperature and weaker corrosion, some other AZS bricks with lower cost may also be considered. At the same time, reasonable maintenance strategies should be formulated according to the actual situation, such as regular inspections and timely replacement of damaged parts.

It is worth mentioning that the fused AZS brick TY - AZS36 has obtained ISO certification, which means it meets international standards. Its high - standard parameters, such as a cold - pressing strength ≥300MPa, also provide reliable quality assurance. The following is a quote from industry authoritative standards:

"For high - temperature kiln lining materials, the cold - pressing strength should be no less than 300MPa, and the high - temperature corrosion resistance rate should be ≤1.3mm/24h to ensure the long - term stable operation of the kiln." - Industry Standard Summary

In conclusion, the fused AZS brick TY - AZS36, with its excellent chemical composition, unique microstructure, and high - standard performance parameters, has become a reliable choice for high - temperature kiln lining materials. Whether it is to improve the service life of the kiln or enhance the stability of equipment operation, it can play an important role. If you want to know how the fused AZS brick TY - AZS36 can help your kiln operate stably, please click to view the complete technical white paper.