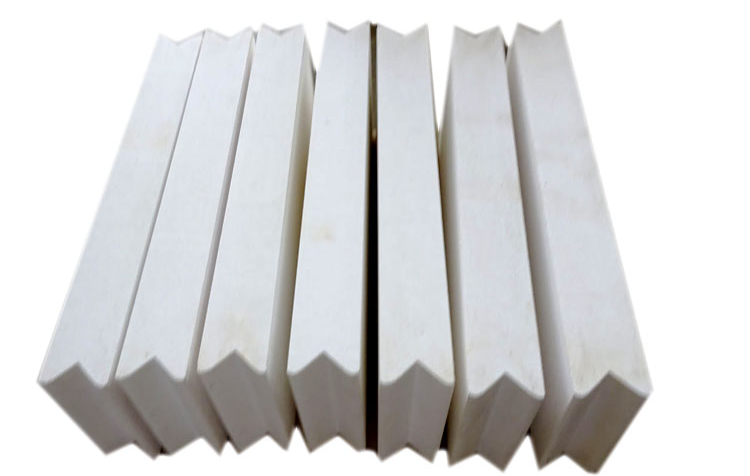

The fused AZS TY-AZS33 refractory block has become an indispensable material in the glass manufacturing industry due to its exceptional durability and resistance to corrosive glass melt environments. Engineered primarily from a balanced composition of alumina (Al2O3), zirconia (ZrO2), and silica (SiO2), this product delivers a dense microstructure, ensuring outstanding performance and longevity in demanding glass melting furnace applications.

The manufacturing process of the fused AZS TY-AZS33 involves an electric fusion technique, which results in a homogeneous and dense microstructure with minimal porosity. This microstructural refinement is critical, as it imparts superior resistance against chemical attack by molten glass and mechanical wear during furnace operation. The optimal content of zirconia enhances thermal stability and corrosion resistance, setting TY-AZS33 apart from conventional AZS bricks.

The fused AZS TY-AZS33 meets the rigorous demands of various critical zones within glass melting furnaces, including:

The core competitive advantage of fused AZS TY-AZS33 lies in its superior resistance to glass melt corrosion. Thanks to its tightly packed microstructure and optimized AZS ratio, this refractory minimizes surface erosion and wear, thereby significantly extending the furnace lining lifespan. Laboratory tests demonstrate that TY-AZS33 blocks maintain structural integrity after continuous exposure to aggressive glass melts at temperatures exceeding 1600°C.

| Performance Metric | Value | Industry Benchmark |

|---|---|---|

| Porosity (%) | Less than 10 | 15–20 |

| Density (g/cm³) | 3.45 | 3.1–3.3 |

| Service Life (months) | 10–16 | 6–10 |

Numerous glass manufacturing facilities worldwide have reported extended furnace campaign lengths and reduced maintenance downtime after adopting fused AZS TY-AZS33 refractory linings. For example, a leading European glass producer noted a 30% increase in furnace lining life, directly translating into significant energy savings and higher production throughput. The enhanced thermal shock resistance also enabled the operator to optimize furnace heating cycles without sacrificing reliability.

Compared to conventional fused or sintered AZS bricks, TY-AZS33's unique formulation offers higher zirconia stability, which drastically minimizes grain boundary corrosion. The dense microstructure limits glass infiltration, and its electrical fusion manufacturing technique ensures uniformity across batches, providing consistency crucial for large-scale production environments. This translates into reduced installation costs, lower operational risks, and a significantly higher total cost of ownership advantage.

For manufacturers and procurement professionals seeking enhanced durability and operational stability, fused AZS TY-AZS33 stands out as a reliable, high-performance material that positively impacts both production efficiency and furnace lifespan.

Want to learn how fused AZS TY-AZS33 can elevate your glass production process and extend furnace life? Contact us today for expert advice and tailored solutions!