In the high-temperature industrial environment, the demand for high-performance refractory materials is constantly increasing. Among these, AZS (Alumina-Zirconia-Silica) crucible bricks have become a critical component in various applications such as glass melting, metal smelting, and ceramic manufacturing. This article provides an in-depth look at the AZS crucible brick manufacturing process, highlighting the key steps that ensure superior quality and performance.

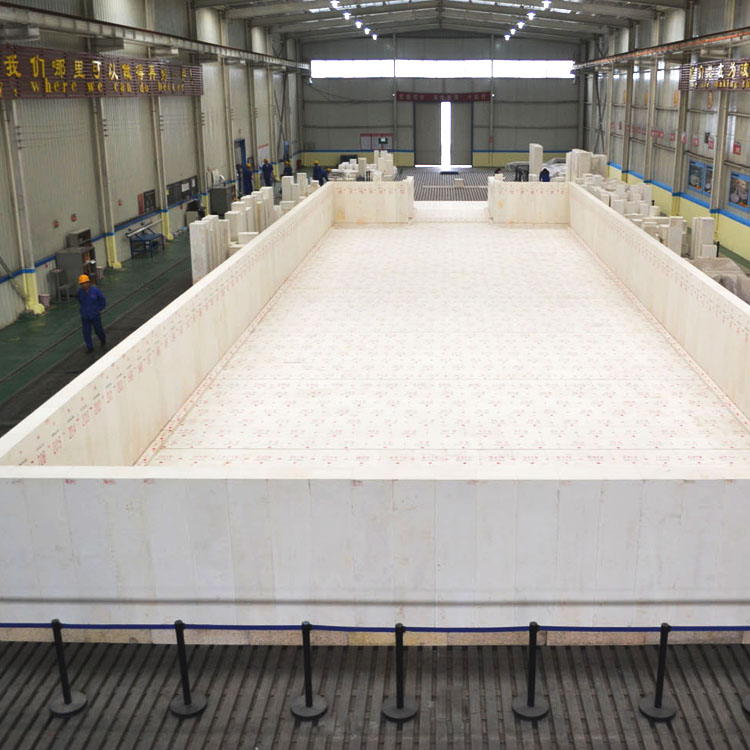

The production of AZS crucible bricks begins with the careful selection of raw materials. High-purity alumina, zirconium oxide, and silica are combined in precise proportions to form a homogeneous mixture. This mixture is then subjected to a high-temperature melting process in an electric furnace, where it reaches temperatures exceeding 1800°C. The molten material is carefully poured into molds, allowing it to solidify into the desired shape. After cooling, the bricks undergo a controlled crystallization process, forming a strong ceramic bond that enhances their mechanical strength and thermal resistance.

This meticulous process ensures that each AZS crucible brick meets the highest standards of durability and reliability. The combination of advanced technology and skilled craftsmanship guarantees consistent quality across all batches.

The quality of AZS crucible bricks is not only dependent on the manufacturing process but also on the use of high-purity raw materials and scientifically formulated compositions. By optimizing the ratio of alumina, zirconia, and silica, manufacturers can enhance the thermal shock resistance and chemical stability of the final product. Additionally, the application of modern production techniques and expert supervision further strengthens the integrity and performance of the bricks.

For example, one leading manufacturer has reported a 30% improvement in thermal shock resistance after refining their formula and adopting a more precise melting technique. Such advancements highlight the importance of continuous innovation in the AZS crucible brick industry.

To ensure compliance with international quality standards, many AZS crucible brick manufacturers have obtained ISO certification. This certification confirms that the production process adheres to strict quality control measures, ensuring consistency, safety, and environmental responsibility. For global buyers, this certification serves as a reliable indicator of product quality and manufacturer credibility.

Compared to traditional refractory materials, AZS crucible bricks offer several distinct advantages. They exhibit higher resistance to thermal stress, better corrosion resistance, and longer service life. In addition, their excellent dimensional stability makes them ideal for use in precision applications. These features make AZS crucible bricks a preferred choice among industries that require high-performance refractory solutions.

With the growing demand for energy-efficient and long-lasting refractory products, the market for AZS crucible bricks is expanding rapidly. Industry reports indicate a projected annual growth rate of 7.5% over the next five years. Customers from various regions have praised the performance and reliability of AZS crucible bricks, citing improved operational efficiency and reduced maintenance costs.

One customer from Germany stated, “Since switching to AZS crucible bricks, our furnace operations have become much more stable. The product’s longevity and performance have significantly reduced downtime.”

As the demand for high-quality refractory materials continues to rise, AZS crucible bricks stand out as a reliable and efficient solution. With a well-controlled manufacturing process, high-purity materials, and adherence to international standards, they provide exceptional value to industrial users worldwide.

If you are looking for a trusted supplier of AZS crucible bricks, we invite you to explore our comprehensive product range and technical specifications. Contact us today to learn more about how we can support your industrial needs.

Explore Our Products Now