In high - temperature tank applications, finding the right refractory material is a significant challenge for global buyers. High - temperature environments subject refractory materials to extreme conditions, such as intense heat, chemical corrosion, and mechanical stress. Traditional refractory materials often fail to meet the long - term performance requirements, leading to frequent replacements and increased costs.

AZS channel bricks, made of fused alumina - zirconia - silicate, emerge as a game - changer. This material is specifically designed for high - temperature tank applications. Compared with other common refractory materials like silica bricks and magnesia bricks, AZS channel bricks have several unique characteristics.

Silica bricks, for example, have a lower melting point of around 1710°C, while AZS channel bricks can withstand temperatures up to 1900°C. Magnesia bricks are more prone to chemical attack in some acidic environments, but AZS channel bricks offer excellent chemical stability due to their special composition. The alumina content in AZS channel bricks can reach up to 45%, zirconia about 36%, and silica around 19%, which together form a dense and stable structure.

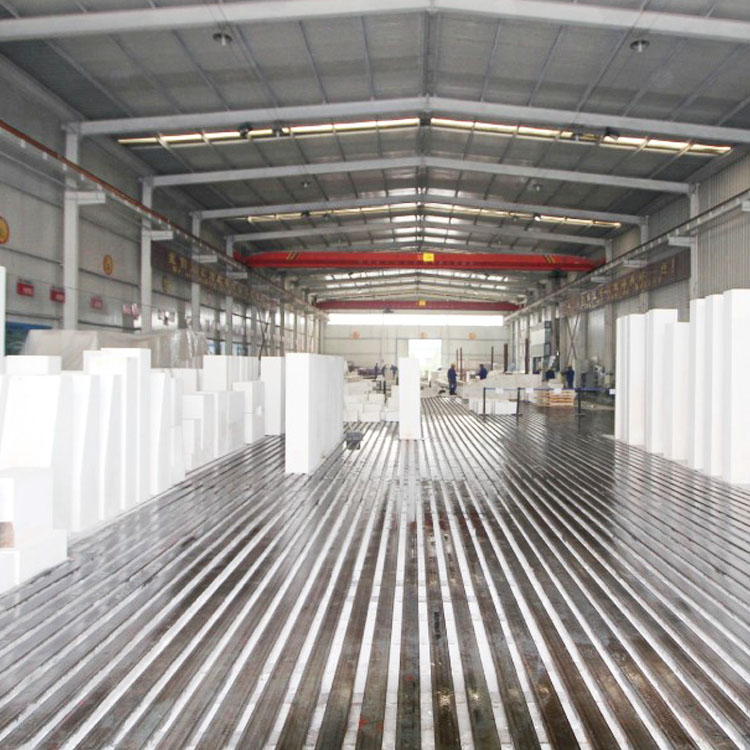

The manufacturing process of AZS channel bricks is a key factor in ensuring their high quality. First, high - purity raw materials are carefully selected. The use of raw materials with an alumina purity of over 99% and zirconia purity of over 98% lays a solid foundation for the final product quality.

The mixture of these raw materials is melted in an electric furnace at a temperature of about 2000°C. After melting, it is cast into molds and slowly cooled to form a ceramic bond. This process ensures a uniform and dense structure of the bricks, which is crucial for their high - temperature resistance and mechanical strength. Moreover, the manufacturing process is strictly in line with ISO standards, and the products have obtained ISO 9001 certification, which is a guarantee of quality and reliability.

In a glass manufacturing plant, traditional refractory materials needed to be replaced every 6 months due to severe erosion and wear. After switching to AZS channel bricks, the replacement cycle was extended to 2 years. This not only reduced the maintenance cost by 70% but also improved the overall production efficiency by 20% because of less downtime for maintenance.

In another metallurgical factory, AZS channel bricks were used in the high - temperature molten metal holding tanks. The chemical stability of AZS channel bricks effectively prevented the corrosion of the tank lining, reducing the risk of leakage and improving the safety of the production process.

Discover the unparalleled advantages of AZS channel bricks for your high - temperature tank applications. Don't miss out on this opportunity to enhance your production efficiency, reduce costs, and improve safety. Contact us today to learn more about our AZS channel bricks and how they can meet your specific needs. Email us at [email address] or call us at [phone number].