In the high-stakes world of glass production, refractory materials aren’t just components—they’re performance drivers. For over three decades, our team has refined the manufacturing process for electric-fused AZS (Alumina-Zirconia-Silica) refractories, particularly the TY-AZS36D grade used in contact zones of glass melting furnaces. This article breaks down how precise control at each stage—from raw material selection to final cooling—directly impacts thermal shock resistance, corrosion resistance, and overall kiln life.

High-purity alumina (≥99.5%), zirconium silicate, and silica are blended using a proprietary ratio that minimizes alkali oxide content—specifically Na₂O and K₂O. Our data shows that reducing these impurities from typical industry levels (~0.8%) to below 0.3% increases the glass phase stability by up to 35%. This translates into fewer micro-cracks during thermal cycling and significantly extended service life in hot zones.

Unlike conventional melting methods, we employ an optimized oxidation step at 1750°C under controlled oxygen flow. This not only volatilizes residual carbon but also reduces free alkali ions in the melt. The result? A denser matrix with fewer pores—measured via SEM imaging—as shown in our internal lab tests where porosity dropped from 12% to 6.5% across 100+ batches.

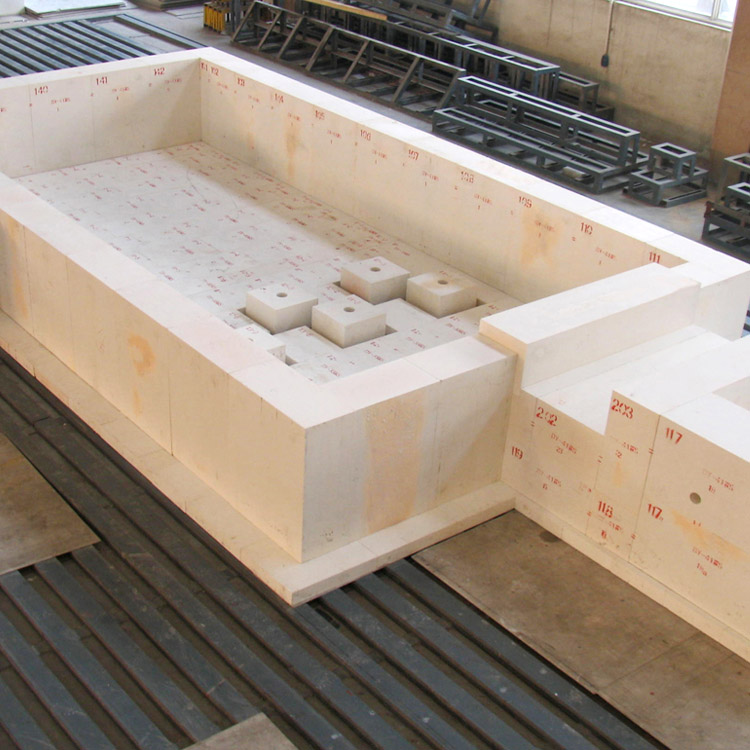

Once molten, the liquid is poured into preheated molds at 1350°C, followed by a staged cooling curve: slow cooling (≤50°C/hour) for the first 4 hours, then natural air cooling. This prevents internal stresses and ensures uniform crystallization. In real-world applications, this method yields a flexural strength of 85 MPa at room temperature—exceeding ISO 5072 standards—and maintains >80 MPa after 100 thermal cycles (from 1000°C to ambient).

For engineers managing furnace downtime or procurement teams evaluating long-term ROI, understanding the science behind these steps isn't optional—it’s essential. Whether you're designing a new melter or troubleshooting premature failure, knowing how chemistry meets process can make the difference between routine maintenance and unexpected shutdowns.

Our 30-year track record includes installations in over 40 countries—from European float lines to Middle Eastern container plants—where consistent performance under extreme conditions has earned trust. We don’t just sell bricks—we provide solutions grounded in repeatable processes, validated metrics, and real-world outcomes.

Discover detailed case studies, application guides, and technical specifications tailored for glass plant engineers and procurement professionals.

Access Our Technical Resource Center