In the demanding environment of float glass production, furnace lining integrity directly impacts product quality, energy efficiency, and operational uptime. Traditional AZS refractory bricks often fail prematurely—especially in contact zones where molten glass attacks the brick surface through crystallization and chemical erosion. But what makes TY-AZS36D stand out? The answer lies not just in material composition, but in a meticulously controlled manufacturing process that delivers measurable performance gains.

The journey begins with high-purity raw materials—zirconia (ZrO₂), alumina (Al₂O₃), and silica (SiO₂)—carefully selected to minimize impurities like Fe₂O₃ and TiO₂. These are then blended using precise ratios (typically 36% ZrO₂, 60% Al₂O₃, 4% SiO₂) to optimize thermal expansion compatibility with the glass melt. This is followed by electric melting at temperatures exceeding 1900°C—a critical step that ensures homogeneity and minimizes microstructural defects.

What truly sets TY-AZS36D apart is its advanced oxidation treatment phase. By controlling oxygen partial pressure during cooling, manufacturers reduce Na₂O content from typical levels (>2.0%) down to ≤1.35%. This small change has a massive effect: it raises the onset temperature for glass phase析出 (crystallization) from ~1300°C to over 1400°C. In practical terms, this means less structural degradation under prolonged exposure to 1550–1600°C operating conditions.

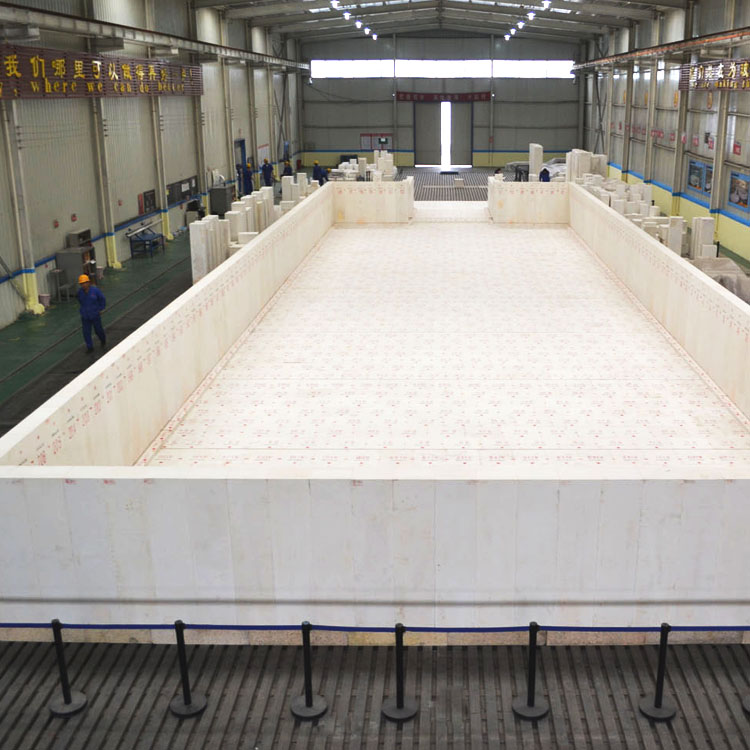

Based on over 30 years of field experience across Asia, Europe, and North America, TY-AZS36D consistently demonstrates superior service life compared to standard AZS bricks. In one case study from a major European flat glass producer, replacing conventional AZS with TY-AZS36D extended furnace campaign duration from 36 months to 52 months—with no increase in maintenance costs or downtime due to refractory failure.

Key metrics include:

Choosing the right brick is only half the battle. Proper installation, temperature management, and atmosphere control are equally vital. For example, maintaining stable furnace atmospheres (especially reducing conditions near the crown) can prevent unwanted redox reactions that accelerate zirconia decomposition. Similarly, avoiding sudden temperature spikes above 1650°C helps preserve the brick’s optimized glass phase structure.

Our engineers recommend conducting regular thermographic inspections every 6 months and implementing a predictive maintenance plan based on real-time data from thermocouples embedded in the brick lining.

All TY-AZS36D bricks meet ISO 9001 standards, undergo rigorous batch testing for consistency, and are produced by certified metallurgists with decades of refractory expertise. Every kiln batch includes traceable documentation—from raw material certificates to final lab reports.

Explore how TY-AZS36D has helped global glassmakers achieve longer campaigns, fewer shutdowns, and higher yield rates.

See Real Application Cases →