In the demanding environment of float glass furnaces, where temperatures exceed 1400°C, maintaining refractory integrity is not just a challenge—it’s a critical factor in production efficiency and cost control. The consistent performance of our TY-AZS36D electric-fused AZS bricks—with documented continuous operation exceeding 18 months without visible erosion—isn’t accidental. It stems from a meticulously engineered manufacturing process that prioritizes purity, structural stability, and thermal resilience.

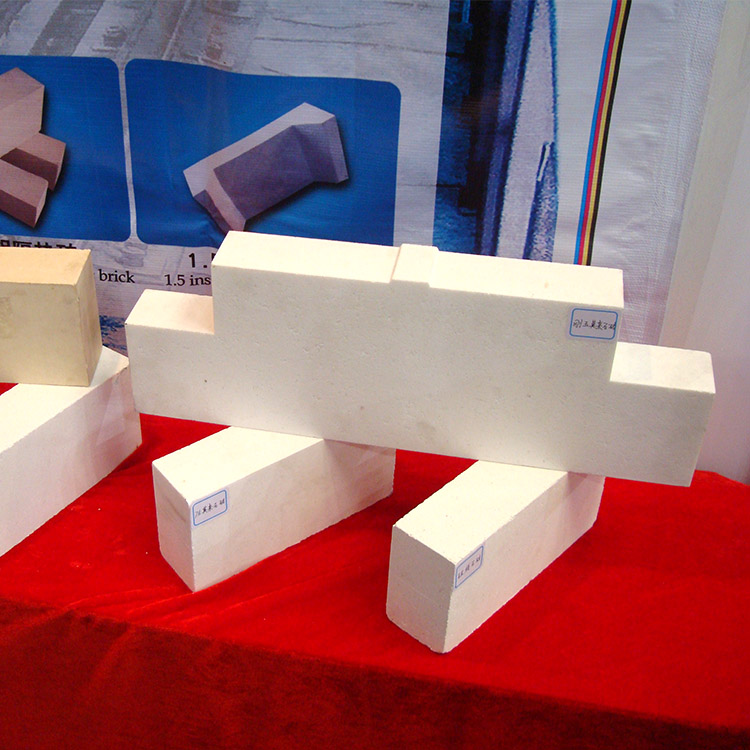

Our process begins with high-purity alumina-silica-zirconia (AZS) raw materials, carefully selected to minimize impurities such as iron oxide and alkali metals. Unlike traditional sintered bricks, TY-AZS36D undergoes a two-stage electric melting process at over 1750°C. This ensures complete homogenization of the melt—a key step in reducing microstructural defects that lead to premature failure under thermal cycling.

What sets us apart? We implement an advanced oxidation stage during the molten phase. By controlling oxygen partial pressure, we reduce Na₂O + K₂O content to below 1.35%, which significantly stabilizes the glassy phase and delays crystallization at operating temperatures. Think of it like refining steel: precise chemistry leads to superior mechanical properties—not just in theory, but in real-world service life.

Over three decades, we’ve tracked installations across 20+ float glass lines and bottle kilns worldwide. In one case study from a Middle Eastern manufacturer, TY-AZS36D bricks in the crown section showed no measurable weight loss or crack propagation after 18.7 months—far outperforming standard AZS bricks that typically degrade within 8–12 months under similar conditions.

This isn't just about longevity—it's about predictability. With fewer unplanned shutdowns for refractory replacement, customers report reduced downtime costs by up to 22% annually. That’s data-driven confidence, not marketing fluff.

The science behind this durability lies in how the material responds to heat shock. At temperatures above 1400°C, the glassy phase in TY-AZS36D resists devitrification longer than conventional formulations—an attribute directly linked to its lower alkali content and optimized cooling schedule post-casting.

Whether you're an engineer evaluating refractory options or a procurement manager seeking reliable suppliers, understanding these technical nuances helps avoid costly missteps. We don’t sell products—we deliver proven solutions backed by decades of field experience and rigorous testing protocols.

Explore detailed technical datasheets, case studies, and process diagrams tailored for engineers and decision-makers.

Download Technical Whitepaper – Free Access