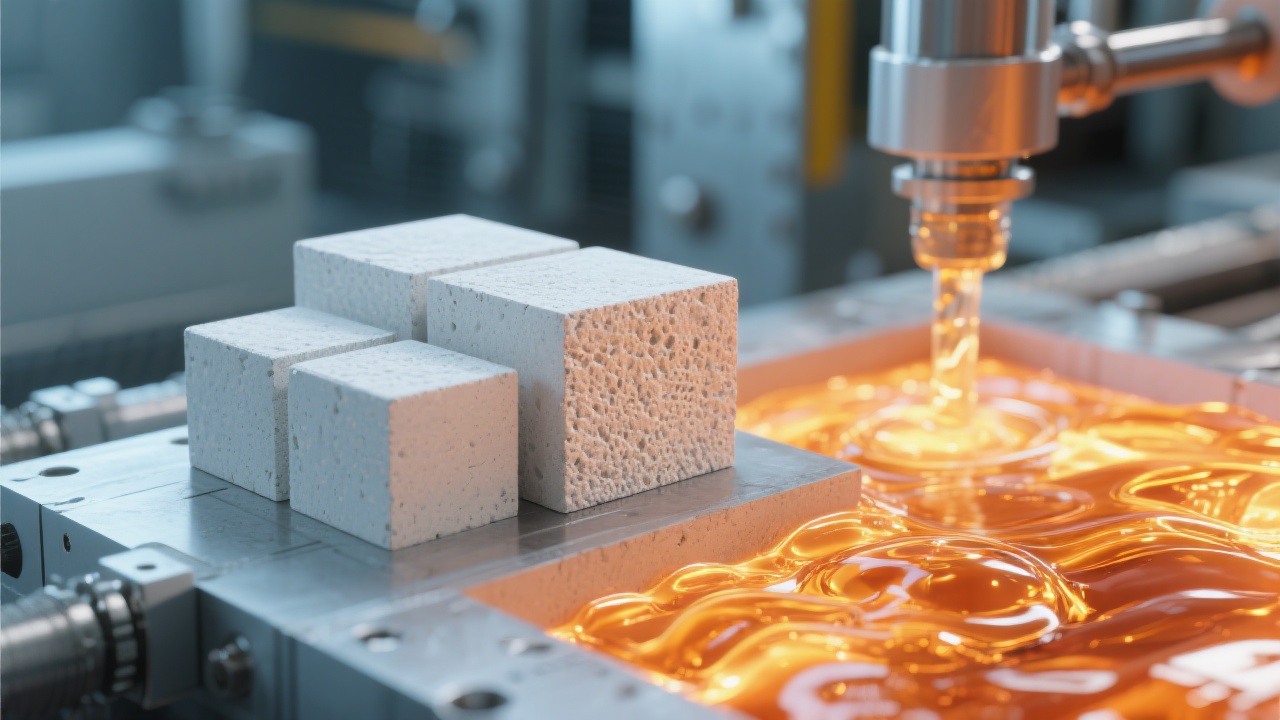

In the glass industry, reliable furnace operation is the lifeblood of production efficiency. Yet, one recurring hurdle you may face is the premature failure of refractory linings—often a silent culprit behind unplanned shutdowns and costly repairs. Among refractory materials, electrofused AZS cast blocks (AZS 33#) stand out as game-changers in boosting furnace durability and performance due to their dense microstructure and exceptional resistance to molten glass corrosion.

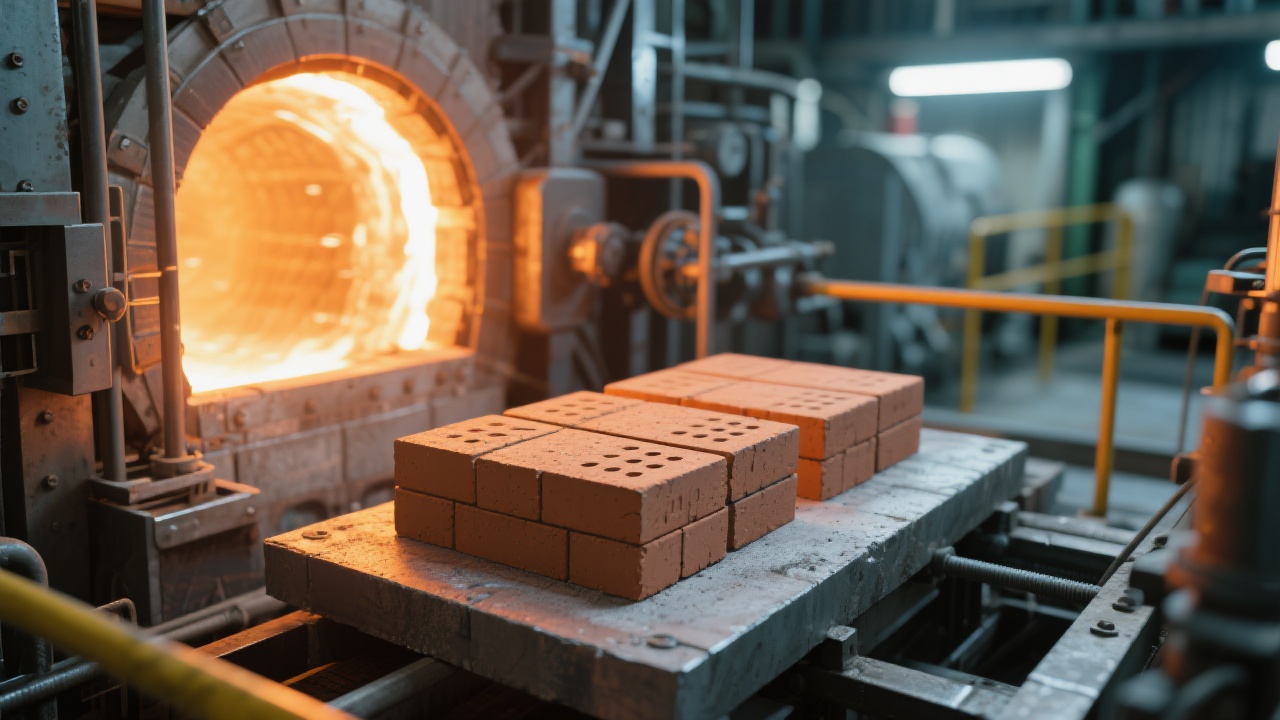

During prolonged melting cycles exceeding 1400°C, traditional refractory bricks often degrade from chemical attack and mechanical stress, resulting in cracking, scaling, or crystallization. You must understand that such damage is not merely a material problem but a direct threat to furnace uptime — increasing maintenance frequency and lowering glass quality consistency.

AZS (Alumina-Zirconia-Silica) blocks typically feature about 33% Al2O3, with well-integrated ZrO2 and SiO2. This unique combination brings you two key benefits:

Think of it like a composite shield where zirconia particles act as anchors in a smooth alumina-silica matrix—together guarding your furnace lining from rapid wear.

Not all furnace areas share the same thermal and chemical exposure. You should tailor AZS block use accordingly. For example:

| Furnace Zone | Temperature Range (°C) | Recommended AZS Block Type | Application Notes |

|---|---|---|---|

| Upper Furnace Structure | 1200–1350 | Standard fused AZS 33# blocks | Resist corrosion while accommodating moderate thermal cycling |

| Working Sidewalls | 1350–1450 | High-density, high-purity AZS | Critical protection against molten glass attack and thermal gradients |

| Charging Channels | 1100–1300 | AZS blocks with optimized grain size | Enhanced mechanical strength to handle abrasive raw materials |

| Furnace Bottom (Including C-Type Bricks, Fire Granule Layers) | 1400–1500 | Specialized AZS with zirconia-rich phases | Maximize lifetime under severe chemical and thermal stress |

Case Example: Our client from Central Europe reduced sidewall repair cycles by 30% after switching to a high-density AZS block arrangement tailored to their furnace’s temperature gradient (see Figure 1 for a typical furnace temperature distribution).

Here’s where theory meets practice. Several critical steps must be carefully managed:

Many installations suffer from rushed preheat or uneven joint treatment. We saw a South American glass plant cut refractory damage rates by half simply through enhanced training on these installation details.

Ongoing surveillance ensures longevity. Your maintenance routine should incorporate:

Expert Insight: “Integrating predictive analytics from real-time thermocouple data has transformed maintenance scheduling in several top glass manufacturing plants, significantly improving furnace uptime,” says Dr. Emma Rodriguez, refractory materials consultant.

The future is promising: next-gen AZS blocks with nano-engineered grain boundaries offer ultra-high corrosion resistance. Meanwhile, embedding IoT sensors into refractory linings facilitates real-time condition tracking, enabling preemptive maintenance decisions.

While these enhancements sound futuristic, pilot projects in North America have already achieved measurable reductions in unscheduled downtimes by 20–25%. That said, this conclusion needs further validation across diverse furnace types.

Master these 5 key steps — optimal AZS selection, strategic placement, meticulous installation, rigorous maintenance, and embracing innovation — to minimize downtime, maximize production lines, and keep your glass melting furnace running rock-solid!