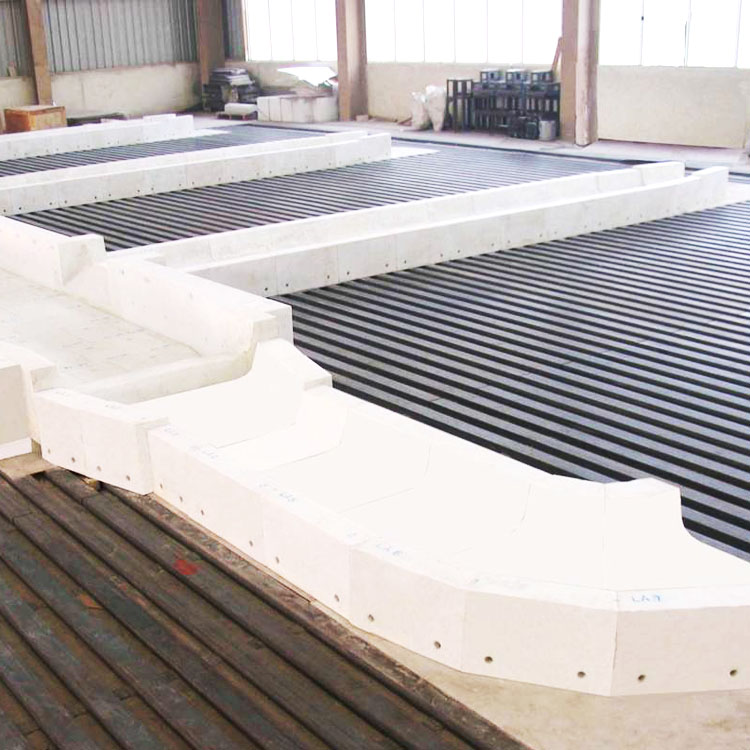

In the demanding environment of glass melting furnaces, operational uptime and material durability remain critical. Frequent downtime due to refractory erosion substantially inflates maintenance costs and shortens equipment lifespan. The top-side components of glass melting furnaces are particularly vulnerable, where corrosion by molten glass and thermal shocks plague traditional refractory materials. Addressing these challenges, the e-fused AZS33# block stands out with its advanced microstructure and superior high-temperature stability, becoming the preferred choice for key furnace zones such as the feeding channel, tank bottom, and hopper top.

The AZS33# block is composed primarily of a chemically optimized mix of alumina (Al₂O₃), zirconia (ZrO₂), and silica (SiO₂). This precise ratio—approximately 33% alumina combined with a stable zirconia-silica matrix—not only forms a highly dense microstructure but also is achieved through the sophisticated e-fusion manufacturing process instead of traditional sintering. The e-fusion technique induces homogeneous melting and rapid solidification, leading to a tightly bonded crystalline phase with minimal porosity.

The glass industry’s furnace environment demands refractory materials to endure aggressive chemical corrosion from molten glass, severe thermal cycling, and mechanical stresses. AZS33#’s dense microstructure dramatically reduces glass infiltration and corrosive attack by minimizing grain boundary phases vulnerable to erosion. Moreover, its inherent low thermal expansion and excellent thermal shock resistance mitigate cracking risks induced by rapid temperature changes during furnace operation.

For practical context, in the feeding channel and tank bottom—areas notorious for intense glass flow and thermal gradients—AZS33# blocks demonstrate usage lifespans up to 20-30% longer compared to conventional fused silica or high-alumina bricks, directly translating into less frequent shutdowns.

| Material | Average Lifespan (Months) | Maintenance Frequency (per year) | Relative Total Cost* |

|---|---|---|---|

| E-Fused AZS33# Block | 18-24 | 1 | 1.0 (Baseline) |

| Fused Silica Brick | 12-15 | 2 | 1.3 |

| High Alumina Brick | 10-14 | 3 | 1.6 |

| Zircon Sand Brick | 8-12 | 4 | 1.8 |

*Relative Total Cost factors in purchase price, installation, maintenance downtime, and repair expenses over equivalent lifespan.

The AZS33# blocks exhibit versatility across multiple furnace components. Their application in the feeding channel, hopper top, and tank sidewall ensures a cohesive thermal barrier with minimal joints and consistent performance. Unlike conventional refractory materials which require frequent replacement in these high-wear areas, AZS33# blocks reduce unscheduled maintenance interventions, directly lowering operational costs and enhancing furnace running efficiency.

Compliance with industry standards such as GB/T 24760 further attests to the product’s quality and reliability, providing procurement officers and engineers with added confidence for specification and usage.

As the glass industry continues to demand high uptime and cost-efficiency, adopting refractory materials such as the e-fused AZS33# block emerges as a strategic advantage. Are you evaluating options to extend your furnace component lifespan and optimize maintenance cycles? How has refractory wear affected your operational budget in recent projects?

Discover How AZS33# Blocks Can Reduce Your Furnace Down-Time Today