In the glass manufacturing industry, high-temperature corrosion of refractory materials poses a critical challenge — leading to frequent maintenance, costly downtimes, and unwanted contamination of molten glass. The Fused-Cast α-β Alumina Brick TY-M offers a reliable solution designed specifically to combat these obstacles by delivering superior high-temperature corrosion resistance and chemical stability.

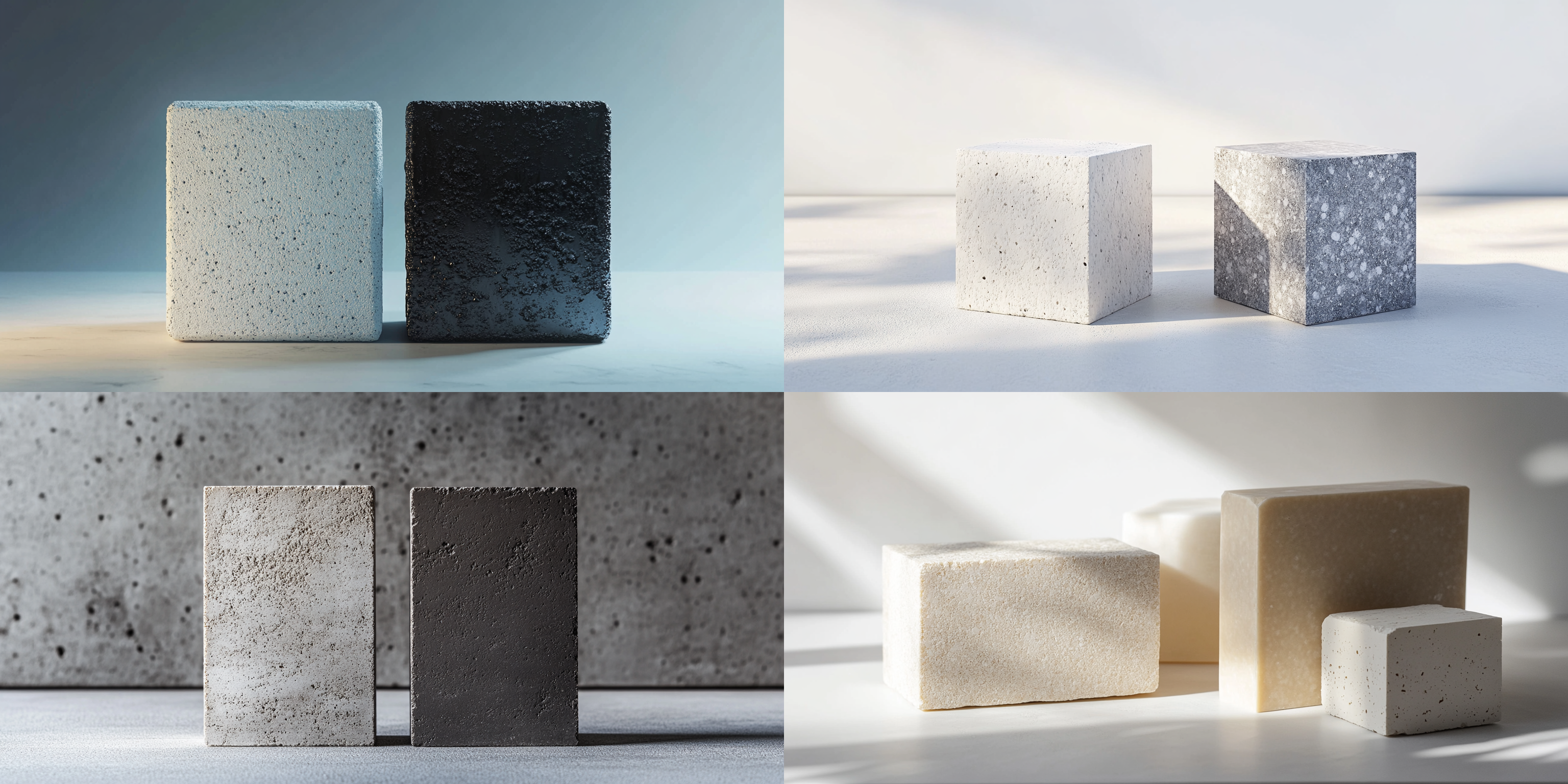

Crafted from ultra-high purity alumina and processed using a state-of-the-art 2000℃ electric furnace fusion technology, TY-M bricks develop a dense α-β corundum (alumina) microstructure. This unique crystalline composition provides exceptional mechanical strength and excellent chemical inertness at operating temperatures up to 1350℃.

Unlike conventional refractory bricks, TY-M bricks are completely free from iron oxide (Fe2O3) and titanium dioxide (TiO2) impurities, significantly reducing the risk of glass-melt contamination and minimizing bubble formation during glass production.

Laboratory corrosion tests demonstrate TY-M bricks maintain structural integrity and resist chemical attack at temperatures below 1350℃, outperforming traditional alumina-silicate refractory materials by 40% in corrosion resistance. This durability translates directly to longer service life, fewer replacements, and uninterrupted glass melting operations.

| Material | Corrosion Depth After 500 Hours (mm) | Service Life Estimate (hours) |

|---|---|---|

| Fused-Cast α-β Alumina Brick TY-M | 0.25 | >7000 |

| Standard Alumina Brick | 0.65 | ~4000 |

| Alumina-Silicate Brick | 0.95 | ~3000 |

The enhanced corrosion resistance of TY-M bricks reduces furnace maintenance frequency, thus lowering replacement costs by an estimated 35%, based on customer feedback from various glass production sites worldwide. These savings are compounded by a significant drop in unplanned production interruptions, directly improving manufacturing throughput and profitability.

Moreover, the absence of Fe2O3 and TiO2 impurities ensures the molten glass remains purer, decreasing defects such as gas bubbles by up to 25% during glass formation. The result is higher product quality with reduced post-production rejection rates.

A leading glass manufacturer in Europe adopted the TY-M bricks in their melting furnace linings last year. After 12 months, they reported:

This real-world example underscores the tangible benefits of integrating TY-M bricks into high-temperature glass production environments, solidifying its position as a key enabler of industrial efficiency and product excellence.

For procurement professionals and plant engineers evaluating refractory materials, Fused-Cast α-β Alumina Brick TY-M offers unmatched reliability, longevity, and purity benefits tailored to the stringent demands of modern glass manufacturing.

Reduce operational risks, extend furnace service life, and elevate glass quality — all while optimizing cost efficiency.

Discover how TY-M bricks can transform your glass production line — contact us today!