In the demanding world of glass manufacturing, maintaining high-quality standards while reducing defects is a constant challenge. One of the most critical components in this process is the use of high-performance refractory materials. Among these, AZS (Alumina-Zirconia-Silica) nozzle blocks have emerged as a reliable solution to enhance production efficiency and product quality.

Glass production involves extreme temperatures that can exceed 1,600°C. Traditional refractory materials often face issues such as thermal shock, chemical corrosion, and material degradation, leading to increased defect rates and production downtime. These challenges not only affect product quality but also raise operational costs and reduce overall productivity.

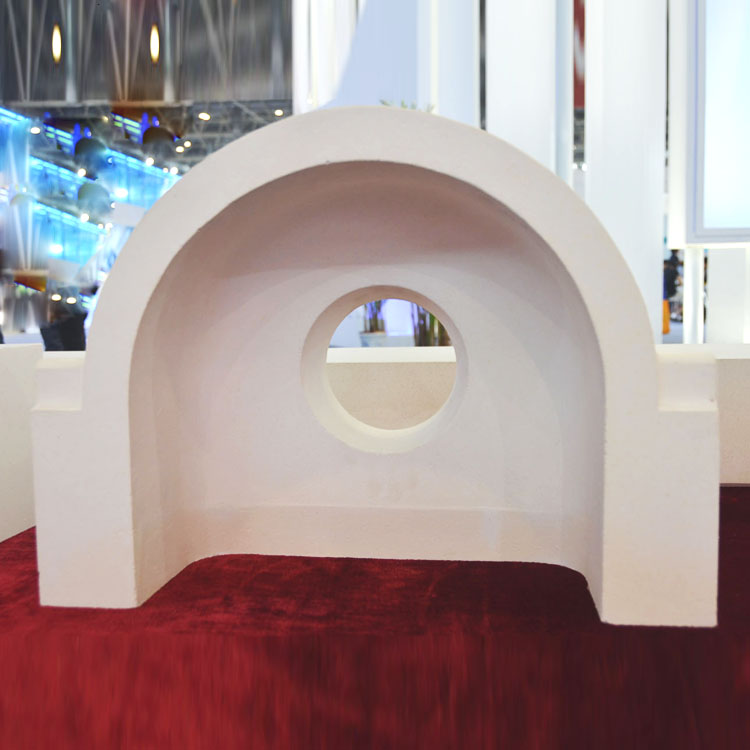

AZS nozzle blocks are engineered to withstand the harshest conditions in glass melting furnaces. Their unique composition offers exceptional performance in terms of heat resistance, thermal stability, and chemical durability. Here are some key advantages:

| Feature | Performance |

|---|---|

| Melting Point | >1,700°C |

| Thermal Shock Resistance | Excellent – withstands rapid temperature changes |

| Corrosion Resistance | High – resists alkali and silica attack |

| Pollution Level | Very Low – minimal contamination of molten glass |

One of the most significant benefits of AZS nozzle blocks is their ability to minimize pollution during the glass-making process. Traditional refractory materials may introduce impurities into the melt, resulting in bubbles, discoloration, or structural weaknesses in the final product. AZS blocks, however, maintain a very low level of contamination, ensuring consistent and high-quality output.

Additionally, their strong anti-spalling properties prevent the formation of flaky layers on the surface, which can lead to material loss and inconsistent flow in the furnace. This contributes to more stable and predictable production outcomes.

Every glass production line has unique requirements based on the type of glass being manufactured, furnace design, and operational parameters. AZS nozzle blocks offer a high degree of customization, allowing manufacturers to choose from a wide range of sizes, shapes, and compositions to suit their specific applications.

For example, one major European glass manufacturer reported a 30% reduction in defect rates after switching to custom-designed AZS blocks. Another client in Asia noted improved furnace efficiency and longer service life of their refractory components.

By choosing AZS nozzle blocks, glass manufacturers can significantly improve their production processes, reduce waste, and enhance product consistency. The combination of high performance and customizable options makes AZS an ideal choice for businesses looking to stay competitive in the global market.

Investing in superior refractory solutions like AZS nozzle blocks isn’t just about improving current operations—it’s about building a foundation for sustainable growth and long-term success.

Don’t miss the opportunity to transform your manufacturing process with high-performance AZS nozzle blocks. Contact us today to discuss your specific needs and receive tailored recommendations.

Get Your Customized Solution Now