In the glass melting industry, kiln longevity under extreme high-temperature corrosive conditions has emerged as a pivotal concern affecting operational efficiency and cost management. The deployment of fusion-cast AZS bricks (TY-AZS36) at critical kiln sections such as the ventilation openings and throat areas significantly mitigates erosion and thermal shock risks. This article delves into the chemical composition and microstructural superiority of these high-purity refractory bricks, explores their practical on-site performance, and discusses systematic maintenance strategies that together forge a sustainable approach to kiln protection.

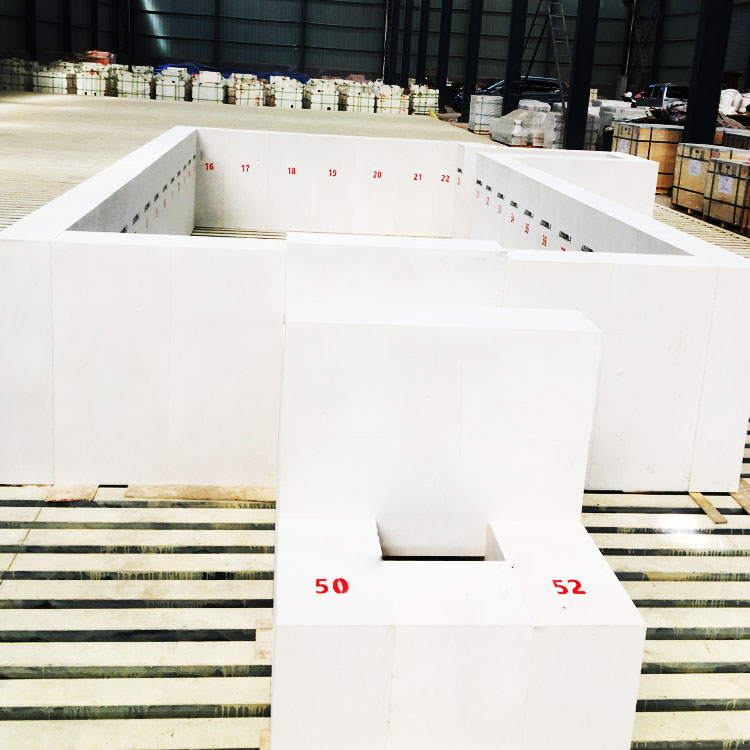

The TY-AZS36 bricks boast an optimized chemical formulation with a minimum of 49% Al₂O₃ and 35.5% ZrO₂. This carefully balanced composition endows the bricks with excellent corrosion resistance. The fusion-casting process produces a dense microstructure characterized by a gas porosity rate below 1.0%, which is crucial in limiting the ingress of molten glass and corrosive agents.

The intrinsic density and microstructural integrity also impart remarkable thermal shock resistance. Cold crushing strength values exceeding 300 MPa testify to the bricks’ capacity to withstand intense thermal cycling without fracturing—critical for kiln zones experiencing rapid temperature fluctuations.

| Parameter | Specification | Benefit |

|---|---|---|

| Aluminium Oxide (Al₂O₃) | ≥ 49% | Enhances chemical stability and corrosion resistance |

| Zirconium Dioxide (ZrO₂) | ≥ 35.5% | Increases thermal shock resistance and structural toughness |

| Gas Porosity | ≤ 1.0% | Restricts corrosive medium infiltration |

| Cold Crushing Strength | ≥ 300 MPa | Maintains mechanical integrity during thermal cycles |

| Corrosion Rate | ≤ 1.3 mm / 24h | Effective minimization of material loss |

Ventilation ports and throat sections of glass melting furnaces are subjected to intense chemical attack from molten glass and hot corrosive gases, accelerating refractory degradation. The employment of TY-AZS36 bricks in these zones effectively reduces bubble entrapment within the melt, which is a common cause of premature brick failure.

Industrial installations report that switching to fusion-cast AZS bricks with the above specifications has resulted in a 30-40% extension of service life in these critical kiln parts. This has a direct impact in reducing costly kiln downtime and maintenance frequency.

Beyond material selection, a systematic maintenance protocol is vital to fully realize the bricks' lifespan benefits. Key measures include:

These operational measures, integrated with the scientifically engineered fusion-cast AZS bricks, create a closed-loop protective strategy that optimizes kiln runtime and safety.

The production of TY-AZS36 bricks complies with international ISO certifications, guaranteeing consistent quality, traceability, and environmental responsibility in manufacturing. This commitment supports green manufacturing trends, increasingly valued in global glass production markets.

Using fusion-cast AZS bricks is not only a technical decision but also a sustainable investment—reducing raw material waste and energy consumption by minimizing shutdowns and brick replacements.

Ready to extend your furnace’s operational life with proven material science? Discover tailored solutions backed by rigorous quality standards and field-tested performance. Click here to learn more about our science-driven approach to kiln protection.

Have questions or want to share your operational experience with fusion-cast AZS refractory materials? Leave your comments below and join the conversation with industry peers and experts.