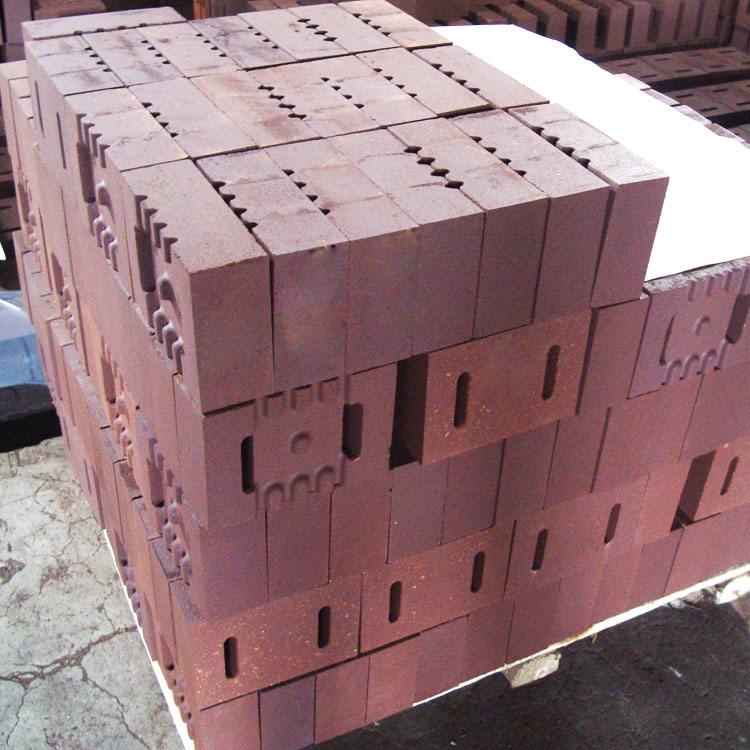

High-temperature applications in industries such as metallurgy, glass manufacturing, and ceramics demand refractory materials that can withstand extreme conditions without compromising performance. Among these, AZS slab bricks have emerged as a top choice due to their exceptional thermal stability, chemical resistance, and durability. This article delves into the features, production process, and advantages of AZS slab bricks, offering insights that help global buyers make informed decisions.

AZS slab bricks are produced through a meticulous process involving electric furnace melting, liquid casting, and solidification into a ceramic bond. The key steps include:

The quality of AZS slab bricks is ensured by a combination of high-purity raw materials, scientific formulation, advanced production technology, and professional technical guidance. Here's how each factor contributes to superior performance:

All AZS slab bricks are manufactured under strict ISO 9001 quality management systems. This certification ensures that every product meets international standards for consistency, reliability, and safety. It also provides buyers with confidence in the product’s performance and compliance with global regulations.

| Feature | AZS Slab Bricks | Traditional Chrome-Magnesite Bricks |

|---|---|---|

| Thermal Shock Resistance | High | Moderate |

| Chemical Stability | Excellent | Limited |

| Service Life | Longer | Shorter |

With the increasing demand for energy-efficient and durable refractory solutions, AZS slab bricks are gaining traction across various sectors. According to recent market reports, the global refractory materials market is expected to grow at a CAGR of 4.2% from 2023 to 2030. AZS products are well-positioned to capture a significant share of this growth due to their superior performance and environmental compatibility.

Industry leaders and end-users have consistently praised the performance of AZS slab bricks. One customer from a steel manufacturing company in South Korea shared:

“Since we switched to AZS slab bricks, our furnace maintenance costs have decreased by 30%. The bricks show no signs of wear even after extended use. We highly recommend them.”

.jpg)

AZS slab bricks offer a compelling combination of performance, durability, and cost-effectiveness for high-temperature applications. Their advanced manufacturing process, rigorous quality control, and proven track record make them a preferred choice among global buyers. Whether you're looking to upgrade your current refractory system or seeking a reliable supplier, AZS slab bricks are an excellent investment.

If you want to learn more about our AZS slab bricks and how they can benefit your operations, visit our website today and discover why so many companies trust us for their refractory needs.