As a glass kiln operator or maintenance technician, you're well aware of the stringent requirements for refractory materials in critical parts of glass melting furnaces. The high temperatures, corrosive environments, and mechanical stresses demand materials that can withstand these harsh conditions over extended periods. In this article, we'll delve into the world of TY - AZS36 refractory bricks and explore how they can meet these challenges, offering solutions to extend the lifespan of your glass kilns.

The key components of a glass kiln, such as the side walls, throat, and electrode seals, are constantly exposed to extreme heat and chemical corrosion. For example, the side walls are often subject to high - temperature erosion and mechanical wear, which can lead to frequent breakage. This not only disrupts production but also incurs significant costs for repairs and replacements. To address these issues, a refractory material with excellent high - temperature resistance and corrosion protection is essential.

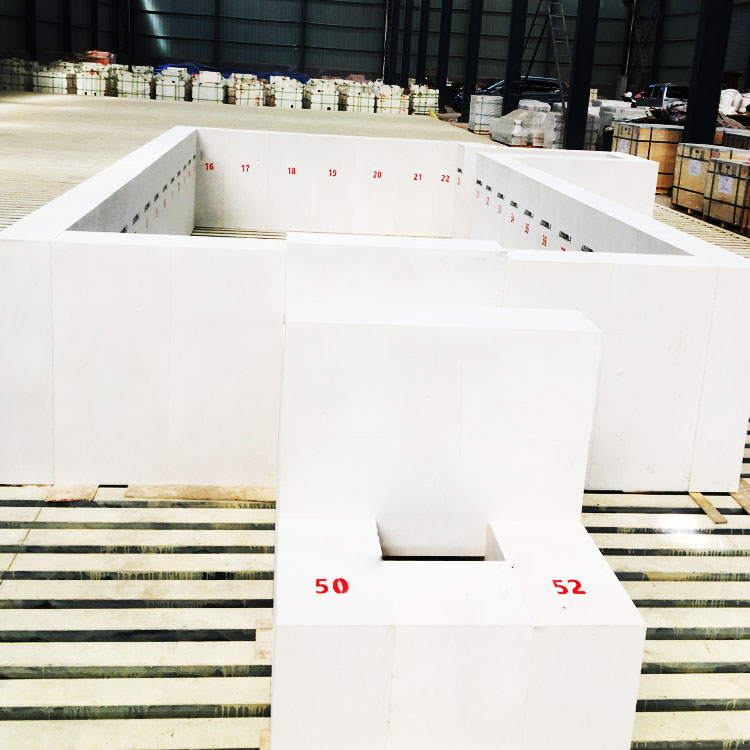

TY - AZS36 refractory bricks are engineered to meet the most demanding requirements of glass kilns. Their high - purity chemical composition, with Al₂O₃ ≥ 49% and ZrO₂ ≥ 35.5%, plays a crucial role in their performance. These chemical elements contribute to a dense microstructure, which is the foundation of their outstanding corrosion resistance and thermal shock stability.

The high alumina content provides excellent refractoriness and mechanical strength, while the zirconia enhances the material's resistance to chemical attack. This combination results in a material that can withstand the high temperatures and corrosive environments inside the glass kiln. For instance, the cold - crushing strength of TY - AZS36 is ≥ 300MPa, and the apparent porosity is ≤ 1.0%. These data indicate its high density and low permeability, which are vital for preventing the penetration of molten glass and corrosive gases.

Let's take a look at some real - world scenarios. In many glass kilns, the side walls are prone to frequent damage. The high - quality TY - AZS36 bricks can be used in these areas to effectively reduce the occurrence of such problems. Their excellent corrosion resistance reduces the formation of bubbles in the glass, improving the quality of the final product. Moreover, they can significantly extend the life of the kiln, reducing downtime and maintenance costs.

When used in the throat and electrode seals, TY - AZS36 also shows remarkable performance. Its thermal shock stability ensures that it can withstand sudden temperature changes without cracking, while its chemical resistance protects against the aggressive chemicals present in these areas. This results in a more stable and efficient operation of the glass kiln.

To fully utilize the benefits of TY - AZS36 refractory bricks, proper maintenance is crucial. We recommend a comprehensive maintenance plan that includes temperature gradient control, regular thickness measurement, and abnormal point marking. By controlling the temperature gradient, you can prevent thermal stress from causing damage to the bricks. Regular thickness measurements help you monitor the wear of the bricks, allowing you to plan for replacements in a timely manner. Marking abnormal points enables you to quickly identify and address potential problems.

Here is a suggested maintenance cycle diagram:

By following these maintenance strategies, you can effectively manage the maintenance cycle, reduce downtime costs, and achieve energy - efficient production.

TY - AZS36 refractory bricks are produced in accordance with ISO standards, which ensures their quality and reliability. The ISO certification is a guarantee of the product's compliance with international quality management systems.

ISO certification indicates that our manufacturing processes meet strict international standards, ensuring consistent quality and performance of TY - AZS36 refractory bricks.

Moreover, in line with the trend of green manufacturing, TY - AZS36 is designed to be energy - efficient and environmentally friendly. Its long lifespan and high performance contribute to reducing waste and energy consumption, making it a sustainable choice for your glass kiln operations.

We encourage you to share your experiences and ask questions in the comments section below. Your feedback and insights can help us improve our products and services, and also provide valuable information for other glass kiln operators. By participating in this discussion, you can contribute to the UGC content, which will enhance the SEO weight of our website and help more people find useful information.

If you're interested in learning more about the detailed parameters of TY - AZS36 refractory bricks, click here to visit our product page and discover how these bricks can transform your glass kiln operations.