In float glass production, the selection of refractory materials directly impacts furnace longevity, production stability, and ultimately the quality of the glass product. A critical, yet often underappreciated factor is the sodium oxide (Na₂O) content in the molten glass and its effect on the stability of the glass phase and crystallization resistance. This article delivers an in-depth, scientifically grounded guide for engineers and procurement specialists on how to optimize refractory material selection by harmonizing the chemistry of the glass melt with operating temperature profiles and maintenance intervals.

Sodium oxide acts as a network modifier in the glass melt, affecting both the viscosity and the tendency of the melt to induce corrosion or crystallization on the refractory lining. High Na₂O levels tend to lower glass viscosity and promote undesirable crystalline phase separation on the refractory surface, accelerating wear and fostering defective glass production.

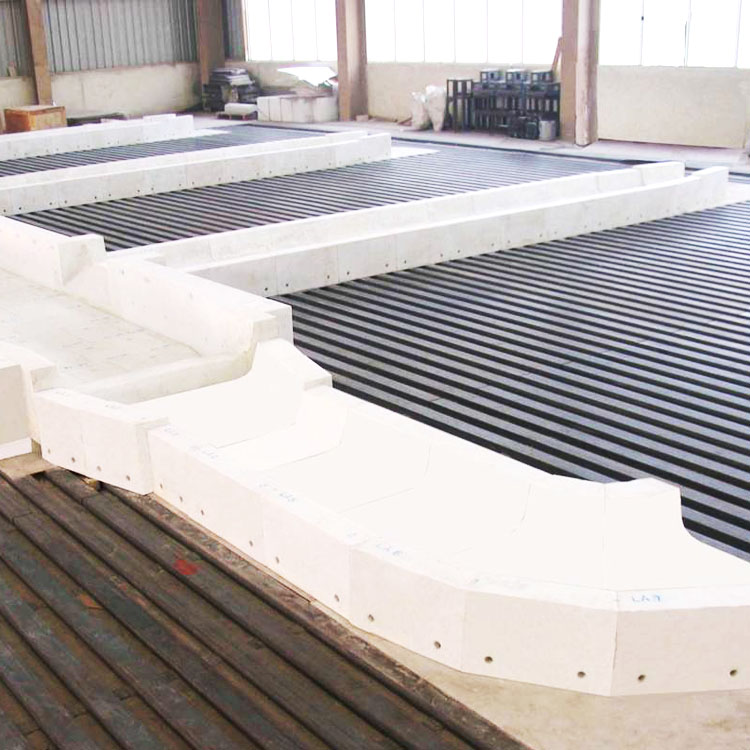

Extensive experimental data confirm that maintaining total alkali content (Na₂O + K₂O) below 1.35% significantly enhances refractory resistance against corrosion and crystallization. This lower alkali design approach is exemplified by the TY-AZS36D material, a low-sodium electrofused alumina-zirconia-silica (AZS) refractory with superior durability compared to traditional AZS36.

The lower Na₂O content in TY-AZS36D reduces the formation of water-soluble crystalline phases and glassy corrosion products at operational temperatures above 1400°C. By stabilizing the glassy phase and discouraging phase separation, the refractory lining maintains integrity longer under extreme thermal and chemical stresses.

This improvement translates into a notable increase in the refractory service life—often exceeding 20%–30% compared to conventional AZS36 materials—alongside a substantial reduction in glass defects such as stones and seeds, enhancing final product yield and reducing costly downtime.

Several float glass manufacturing facilities adopting the TY-AZS36D low-Na refractory have recorded measurable benefits. One leading plant reported a furnace campaign extension from 18 months to over 24 months and a 40% decrease in glass stone-related rejects after switching from traditional AZS36 to the low-alkali alternative.

These results underscore the critical importance of aligning refractory chemistry with the glass batch design, along with precise control of operating temperature gradients—particularly in the melting and conditioning zones where corrosion and crystallization risks peak.

To effectively utilize these findings, manufacturers must integrate three key parameters into their refractory material selection model:

Structuring this model allows engineers and procurement teams to quantitatively evaluate refractory alternatives against operational targets—bridging chemistry, thermodynamics, and economics in a single framework.

The low-sodium TY-AZS36D refractory is backed by over three decades of R&D development, stringent ISO certifications, and comprehensive real-world testing across multiple float glass manufacturing lines worldwide. Choosing this solution ensures stability in product quality and a reduction in maintenance costs unlike any conventional refractory option.

For factories aiming to optimize furnace campaigns, minimize unplanned stops, and deliver a higher-quality glass product, scientifically matching the refractory material with the glass chemistry and thermal conditions is imperative. Choosing us means you’re choosing peace of mind and unparalleled performance—you will never be disappointed.