In the float glass industry, the selection of refractory materials is crucial for the efficient and long - term operation of glass kilns. This article delves into the technical principles behind why float glass plants should give priority to refractory materials with a Na₂O content below 1.35%, such as the TY - AZS36D low - sodium formula.

Na₂O, an alkali metal oxide, has a significant impact on the stability of the glass phase. When the Na₂O content in refractory materials is high, it can disrupt the chemical balance of the glass phase. In the high - temperature environment of a glass kiln, Na₂O can react with other components in the glass, leading to an increase in the fluidity of the glass phase and a decrease in its viscosity. This, in turn, makes the glass phase more prone to crystallization and corrosion. Research shows that when the Na₂O content exceeds 1.35%, the risk of glass phase instability increases significantly.

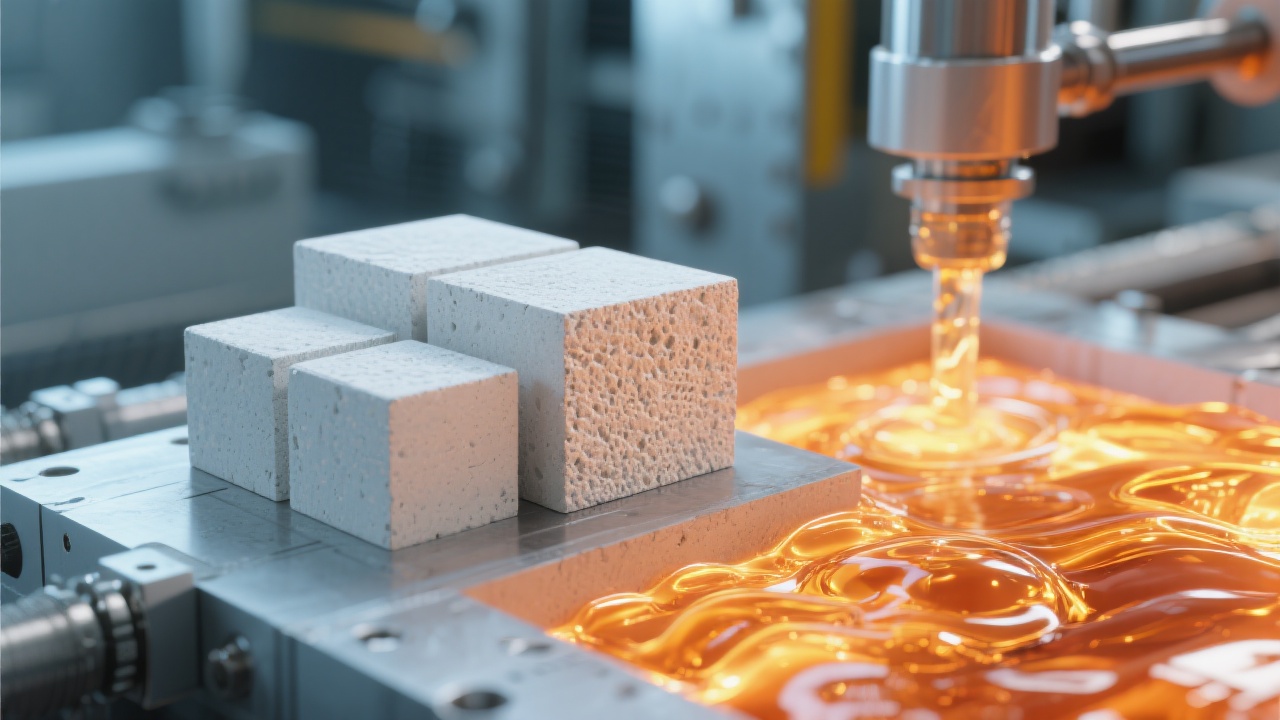

Low - sodium formulas, like TY - AZS36D, are designed to reduce the content of alkali metal oxides in the glass phase. By controlling the Na₂O content below 1.35%, these formulas can effectively inhibit the precipitation of grains in the high - temperature environment of the kiln. At high temperatures, the low - sodium refractory materials maintain a more stable glass phase structure, which helps to prevent the formation of crystalline phases that can cause glass defects and reduce the service life of the kiln.

When comparing traditional AZS refractory materials with TY - AZS36D in the glass contact area, the difference in performance is obvious. Traditional AZS materials with relatively high Na₂O content are more likely to react with the glass, resulting in corrosion and the formation of defects on the glass surface. In contrast, TY - AZS36D, with its low - sodium formula, shows excellent resistance to corrosion and crystallization in the glass contact area. For example, in some long - term operation cases, the corrosion rate of traditional AZS in the glass contact area is about 2 - 3 times higher than that of TY - AZS36D.

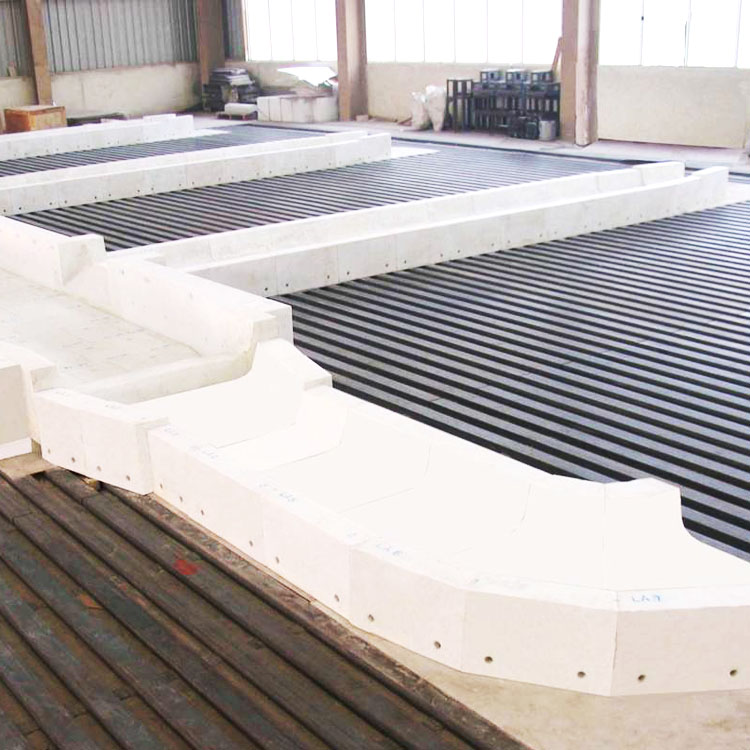

In typical application scenarios such as the side walls of bottle kilns and floor tile areas, the performance advantages of low - sodium refractory materials are well - demonstrated. In bottle kilns, the low - sodium refractory materials can significantly reduce the occurrence of glass defects, such as bubbles and inclusions, ensuring the quality of glass products. In floor tile areas, the high - performance low - sodium refractory materials can withstand the long - term high - temperature erosion, effectively extending the service life of the kiln. For instance, in a bottle kiln side - wall application, the use of TY - AZS36D has extended the kiln's service life by about 2 - 3 years compared to traditional materials.

Selecting the right refractory materials requires considering multiple factors, including glass composition, temperature gradient, and operating cycle. For different glass compositions, the chemical reactions with refractory materials vary. By analyzing the specific glass composition, technicians can determine the most suitable low - sodium refractory material. Temperature gradient also plays an important role. In areas with a large temperature gradient, low - sodium refractory materials with better thermal stability should be selected. Additionally, the operating cycle of the kiln affects the wear and tear of the refractory materials. For long - cycle operations, refractory materials with high corrosion resistance and stability are essential. Our products, with 30 years of实战经验沉淀 and ISO international certification, can provide scientific matching solutions for different application scenarios.

The proper selection of refractory materials can significantly reduce operation and maintenance costs and the risk of kiln shutdown. Using low - sodium refractory materials can extend the service life of the kiln, reducing the frequency of kiln repairs and replacements. Moreover, by reducing glass defects, the quality of glass products can be improved, increasing the economic benefits of the glass plant. A wrong choice of refractory materials can lead to frequent kiln shutdowns for repairs, resulting in huge economic losses. For example, an improper material selection may cause a kiln shutdown for several weeks, resulting in production losses worth hundreds of thousands of dollars.

In conclusion, float glass plants should give full consideration to the Na₂O content in refractory materials. Low - sodium refractory materials, such as TY - AZS36D, offer significant advantages in terms of glass phase stability, corrosion resistance, and anti - crystallization ability. If you are a technical expert or a procurement decision - maker in the float glass industry, download our technical manual for more in - depth information on refractory material selection. Download Technical Manual Now