In the high - temperature industrial sector, the selection of refractory materials is crucial for the efficient and safe operation of kilns. Fused AZS36 refractory bricks have emerged as a top - choice solution, offering a combination of excellent performance and reliability. This article delves into the core technical indicators and application scenarios of these bricks, providing valuable insights for professionals in the field.

The chemical composition of fused AZS36 refractory bricks is a key factor in determining their performance. The typical ratio of Al2O3/ZrO2/SiO2 is around 55%/36%/9%. This specific composition endows the bricks with unique properties. For instance, the high proportion of ZrO2 enhances the brick's resistance to corrosion at high temperatures, while the appropriate amount of Al2O3 contributes to its high strength.

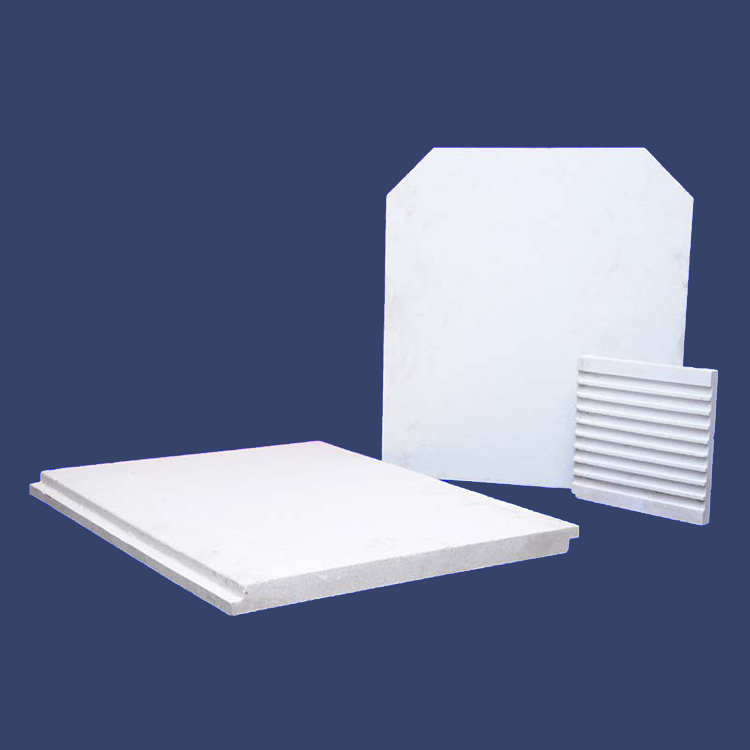

In terms of physical properties, the volume density of fused AZS36 refractory bricks is approximately 3.6 g/cm³, and the apparent porosity is less than 1%. These values indicate a dense and compact structure, which is essential for withstanding harsh operating conditions. The low porosity also helps to reduce the penetration of corrosive substances, thereby improving the overall durability of the bricks.

One of the outstanding features of fused AZS36 refractory bricks is their high cold crushing strength. Tests have shown that these bricks can withstand a pressure of up to 400 MPa, which is significantly higher than that of common AZS bricks. This high strength allows the bricks to maintain their structural integrity under heavy loads, making them suitable for use in areas with high mechanical stress in kilns.

In addition to strength, the high - temperature corrosion resistance of fused AZS36 refractory bricks is also remarkable. Their corrosion rate at high temperatures is as low as 0.1% per hour in a highly corrosive environment. This property makes them an ideal choice for glass melting furnaces and other high - temperature industrial kilns where they are exposed to aggressive chemicals and high - temperature gases.

The ISO international certification plays a vital role in ensuring the quality of fused AZS36 refractory bricks. Products with ISO certification have undergone strict quality control procedures, which guarantee that they meet international standards. This certification not only provides a reliable guarantee for product quality but also enhances the confidence of customers in the product.

When compared with common AZS bricks, the advantages of fused AZS36 refractory bricks are obvious. Their superior performance in cold crushing strength and high - temperature corrosion resistance makes them more suitable for demanding applications in high - temperature industries. These characteristics enable them to meet the requirements of harsh working conditions, such as those in glass melting furnaces.

Fused AZS36 refractory bricks are widely used in various high - temperature industrial kilns, especially in glass melting furnaces. In glass production, the high - temperature and corrosive environment requires refractory materials with excellent performance. The high cold crushing strength and high - temperature corrosion resistance of fused AZS36 refractory bricks make them an ideal choice for lining glass melting furnaces, ensuring the long - term stable operation of the furnaces.

This article provides in - depth information on fused AZS36 refractory bricks, which can serve as a professional reference for procurement officers, technical managers, and kiln design engineers. Whether you are looking to select the right refractory materials or enhance your technical knowledge, this article offers valuable insights. If you want to learn more about the detailed technical specifications and application cases of fused AZS36 refractory bricks, click here to access the detailed technical manual.