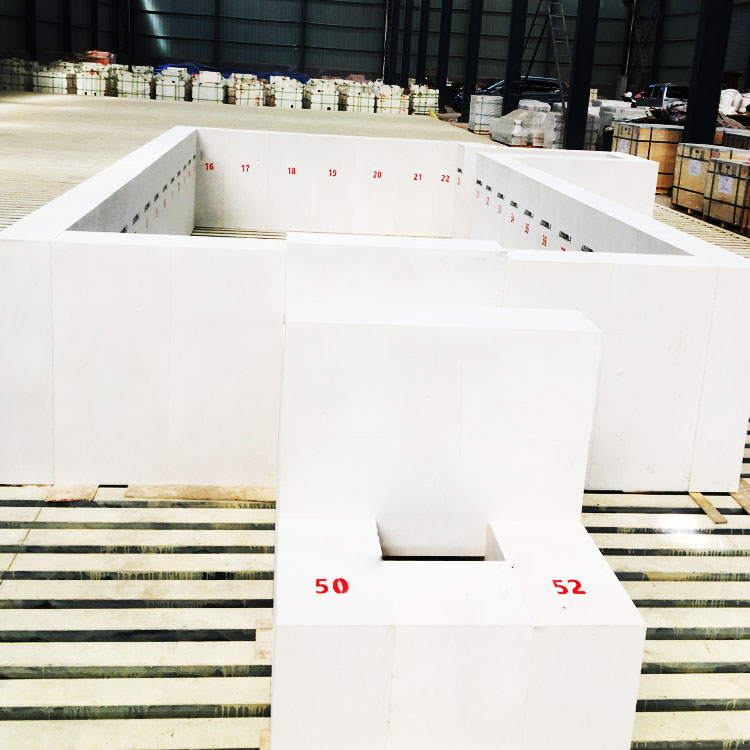

In the demanding environment of glass melting furnaces, sidewall damage caused by repeated high-temperature corrosion and thermal stress significantly impacts operational efficiency and maintenance costs. The innovative E-fused AZS Brick TY-AZS36 offers advanced material properties engineered to resist these harsh conditions, providing a robust solution for glass manufacturers seeking durability and longevity in furnace linings.

The core strength of TY-AZS36 lies in its carefully optimized chemical composition and microstructure:

| Key Component | Content (%) | Benefits |

|---|---|---|

| Aluminum Oxide (Al₂O₃) | ≥ 49% | High refractoriness, improved heat resistance |

| Zirconium Oxide (ZrO₂) | ≥ 35.5% | Enhanced chemical stability, minimized corrosive interactions |

Complementing this composition is the tight microstructure with an apparent porosity rate of ≤1.0%, ensuring minimal infiltration of molten glass and corrosive agents, and a superior cold crushing strength exceeding 150 MPa. This combination significantly mitigates erosion and mechanical failure risks under thermal cycling.

Industrial trials reveal that TY-AZS36 boasts a glass phase precipitation temperature greater than 1400°C, translating to outstanding thermal shock resistance critical for the high-temperature swings in furnace operation. Empirical data from continuous 24-hour high-temperature erosion tests demonstrate an average corrosion rate below 1.3 mm per day, outperforming standard AZS bricks by nearly 20%.

TY-AZS36’s applicability extends across critical furnace zones, including:

Comparative field studies illustrate TY-AZS36’s superior performance, reducing emergency downtime by 30% and extending refractory lining lifespans by up to 25% relative to conventional fused AZS bricks.

To leverage the full benefits of TY-AZS36, a rigorous maintenance regime is essential. Recommended guidelines include:

Integrating these practices with TY-AZS36’s inherent chemical and physical resilience ensures maximized furnace uptime and significantly reduced replacement costs.

Explore the detailed technical parameters and maintenance tips of the TY-AZS36 – discover how to extend your furnace’s service life effectively.

Have specific questions about applying TY-AZS36 in your facility or want guidance on troubleshooting refractory lining issues? Share your experiences or ask our technical specialists in the comments below.