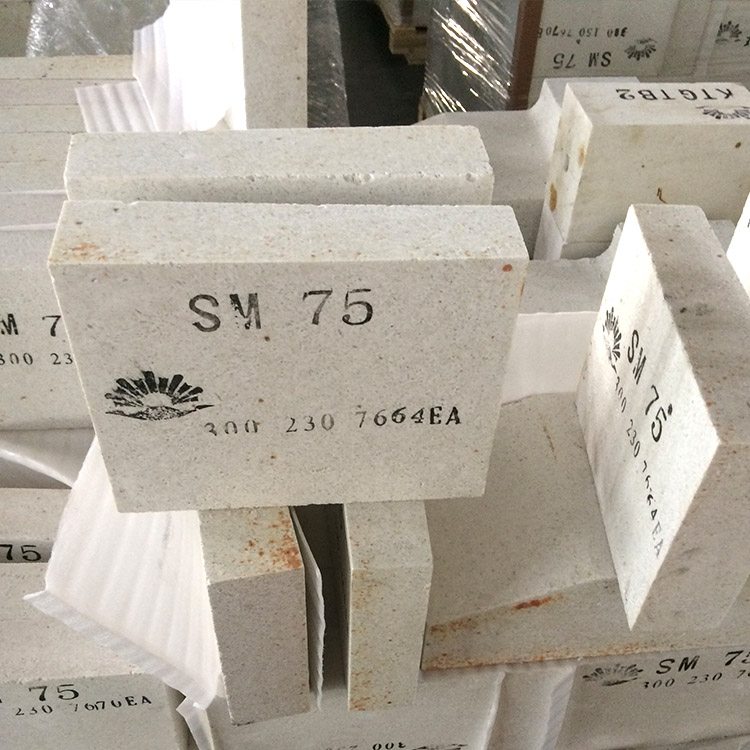

Electro - fused AZS refractory bricks have gained significant popularity in the industry for their high stability and corrosion resistance. This article will take you through the whole process from raw material screening to the cooling system, highlighting the key control points that ensure the quality of these bricks.

The purity and proportion of raw materials play a crucial role in determining the performance of electro - fused AZS refractory bricks. High - purity raw materials can effectively improve the overall quality of the product. For example, by carefully controlling the proportion of various oxides, the glass phase stability can be enhanced. A well - balanced raw material formula can reduce the content of harmful impurities, such as Na₂O. In the oxidation process during electro - fusion casting, the reduction of Na₂O content can significantly improve the quality of the glass phase and its anti - crystallization ability.

Traditional AZS bricks often face issues due to relatively high alkali metal oxide content. In contrast, TY - AZS36D has a lower alkali metal oxide content, which brings about obvious structural optimization. The low - alkali structure makes the brick more stable under high - temperature conditions, reducing the risk of thermal shock cracking. Many engineers have found that when using TY - AZS36D, the service life of the furnace can be significantly extended.

In a typical floating glass furnace, traditional AZS bricks may start to show signs of erosion after about 12 months of continuous operation. However, TY - AZS36D has been proven to support the furnace to run continuously for more than 18 months without erosion, greatly improving production efficiency and reducing maintenance costs.

The refractory industry often faces problems such as thermal shock cracking and accelerated erosion. These issues can lead to unexpected production halts and increased costs. Through strict control of the raw material screening process and the cooling system, we can effectively solve these problems. By optimizing the oxidation process, the anti - crystallization ability of the glass phase is improved, reducing the probability of brick body crystallization that may cause furnace shutdown. Have you ever encountered the problem of furnace shutdown due to brick body crystallization?

TY - AZS36D, with its advanced production technology and strict quality control, can effectively address these industry pain points. The key lies in its low - alkali metal oxide content and superior glass phase stability.

In summary, choosing high - quality electro - fused AZS refractory bricks like TY - AZS36D can bring significant benefits to your production. Understanding the technical details behind these products is crucial for engineers and procurement decision - makers.

To learn more about the application cases and process details of our electro - fused AZS series products, please visit our official website's technical column.