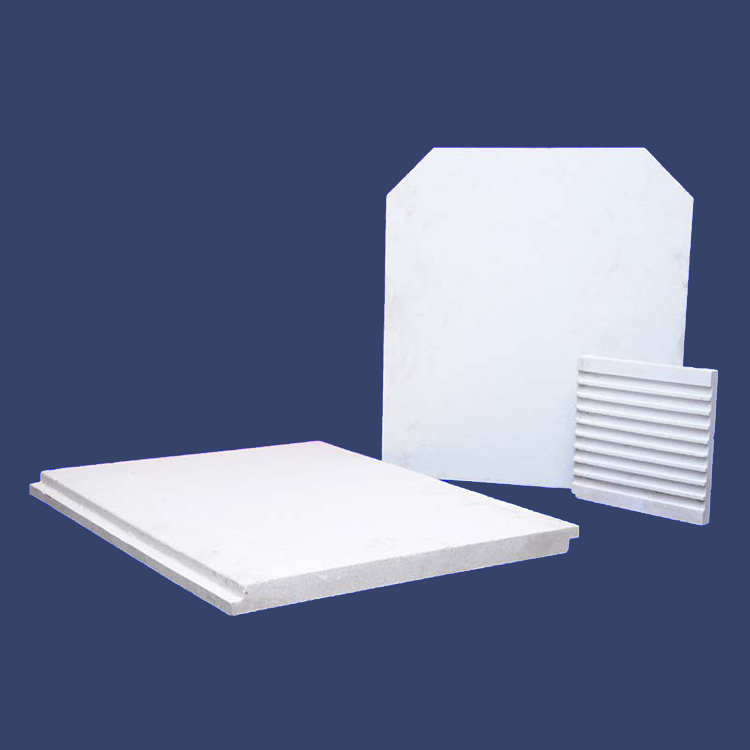

In the demanding environment of glass melting furnaces, selecting the right refractory material is critical to operational stability and cost efficiency. The fused AZS36 refractory brick, specifically the TY-AZS36 variant, is engineered with meticulous chemical and physical parameters that dictate its performance. This guide provides a technical exploration of its core composition and physical properties, offering procurement professionals and engineers a data-driven foundation to improve purchasing quality while minimizing operational risks.

The chemical makeup of fused AZS36 bricks is pivotal to their resilience in high-temperature corrosive environments. The primary constituents include:

| Oxide Component | Minimum/Maximum (%) |

|---|---|

| Aluminum Oxide (Al₂O₃) | ≥ 49% |

| Zirconium Dioxide (ZrO₂) | ≥ 35.5% |

| Silicon Dioxide (SiO₂) | ≤ 13.5% |

Aluminum oxide provides structural stability and abrasion resistance, enhancing the overall toughness of the brick. Zirconium dioxide excels in chemical inertness and high-temperature corrosion resistance, ensuring the furnace lining endures aggressive slags and molten glass. Meanwhile, controlling silicon dioxide content prevents weakening of the matrix and limits thermal expansion discrepancies.

Beyond chemistry, physical characteristics determine durability and operational costs. Key parameters for TY-AZS36 include:

| Property | Specification | Operational Impact |

|---|---|---|

| Bulk Density | ≥ 3.85 g/cm³ | Higher density correlates with improved strength and resistance to deformation. |

| Apparent Porosity | ≤ 1% | A low porosity, akin to minimal skin pores in humans, reduces slag penetration, enhancing corrosion resistance. |

| Cold Crushing Strength | ≥ 300 MPa | High strength ensures structural integrity under mechanical stress and thermal cycling. |

These physical markers are not mere numbers but indicators directly linked to refractory lifetime and maintenance intervals. For example, a porosity below 1% significantly reduces the rate at which molten glass or slag infiltrates the brick, thus preventing premature failures that can lead to costly downtime.

The TY-AZS36 bricks adhere to ISO quality management and product standards specific to refractory materials. Such certifications assure buyers of controlled manufacturing processes, uniform composition, and rigorous testing that align with international benchmarks. This quality management framework mitigates risks in scaling furnace operations by ensuring repeatable material performance.

When benchmarked against typical high-alumina or zircon bricks, TY-AZS36 exhibits a controlled high-temperature corrosion wear rate below 1.3 mm per 24 hours under glass furnace conditions. This metric is crucial; slower wear rates translate to longer service cycles and reduced refractory replacement costs.

In comparison, standard fused alumina bricks often encounter wear rates exceeding 2 mm per 24 hours, especially in aggressive molten glass applications. This difference can impact annual maintenance budgets substantially.

Procurement teams can harness the detailed chemical and physical profiles of TY-AZS36 refractories to:

Leveraging these insights not only elevates the quality of material decisions but also sustains furnace uptime, boosting overall production efficiency.

The interplay of Al₂O₃, ZrO₂, and SiO₂ ratios influences thermal shock resistance — a critical factor in furnace lining endurance. High zirconia content improves crack resistance under rapid temperature fluctuations, while sufficient alumina content maintains crystalline structure integrity.

Silicon dioxide serves to fill microstructural voids but must be carefully limited to prevent increased brittleness. Thus, the ≤13.5% SiO₂ content balances structural flexibility and strength.