Glass furnace lining failure is a common problem in the glass manufacturing industry, which can lead to significant economic losses. There are several common causes of lining failure, including bubble generation, erosion perforation, and thermal shock cracking.

For example, bubble generation can be caused by the reaction between the lining material and the molten glass, which produces gas bubbles. These bubbles can accumulate and cause the lining to fail. Erosion perforation occurs when the lining material is gradually worn away by the molten glass, leading to holes in the lining. Thermal shock cracking is caused by the rapid temperature changes in the furnace, which can cause the lining material to crack.

Let's take a look at a typical case. In a glass manufacturing plant, the lining of a glass furnace failed after only a few months of operation. The failure was characterized by erosion perforation in the side wall of the furnace. After a detailed analysis, it was found that the lining material used was not suitable for the high - temperature and corrosive environment of the furnace. The material had a relatively high porosity, which allowed the molten glass to penetrate and erode the lining.

The microstructure of the glass furnace lining material plays a crucial role in its corrosion resistance. Three key factors are the denseness, grain boundary distribution, and the precipitation temperature of the glass phase.

Denseness is an important factor. A more dense material has fewer pores and channels, which can prevent the penetration of the molten glass. The grain boundary distribution also affects corrosion resistance. A well - distributed grain boundary can act as a barrier to the diffusion of corrosive substances. The precipitation temperature of the glass phase is another critical factor. A higher precipitation temperature means that the glass phase is more stable at high temperatures, which can enhance the corrosion resistance of the material.

For instance, in a study, two samples of lining materials with different microstructures were tested. The sample with a more dense structure and a well - distributed grain boundary showed a significantly higher corrosion resistance than the other sample. This clearly demonstrates the importance of microstructure in corrosion resistance.

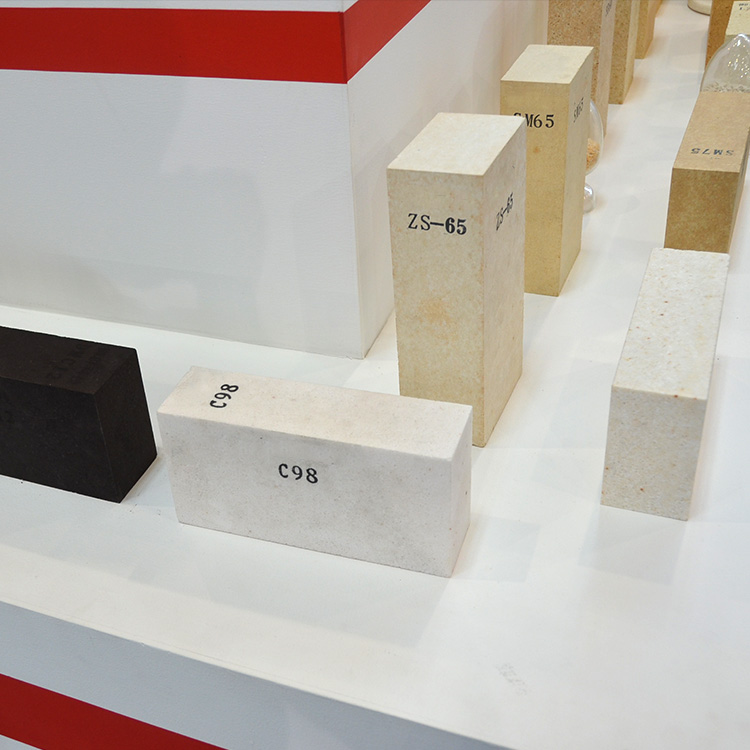

The chemical composition and physical properties of the glass furnace lining material are key to its performance. The ratio of Al₂O₃/ZrO₂/SiO₂, volume density ≥3.85g/cm³, and apparent porosity ≤1.0% are important parameters.

The Al₂O₃/ZrO₂/SiO₂ ratio affects the high - temperature stability and corrosion resistance of the material. Al₂O₃ provides high - temperature strength, ZrO₂ enhances the corrosion resistance, and SiO₂ helps to form a stable glass phase. A proper ratio of these three components can optimize the performance of the material.

The volume density of the material should be at least 3.85g/cm³. A higher volume density means a more dense material, which can resist the penetration of the molten glass. The apparent porosity should be no more than 1.0%. A low porosity reduces the contact area between the material and the molten glass, thus improving the corrosion resistance.

The scientific basis for these parameters comes from extensive research and industry - wide testing. For example, in a series of tests, materials with a volume density of 3.85g/cm³ or higher and an apparent porosity of 1.0% or lower showed much better corrosion resistance than materials with lower density and higher porosity.

To evaluate the performance of TY - AZS36, a comparison test was conducted between TY - AZS36 and ordinary AZS bricks at high temperatures (≥1400℃). The corrosion rate was measured as an important indicator.

| Material | Corrosion Rate (mm/24h) |

|---|---|

| TY - AZS36 | ≤1.3 |

| Ordinary AZS Bricks | Higher than 1.3 |

The results clearly show that TY - AZS36 has a much lower corrosion rate than ordinary AZS bricks at high temperatures. This means that TY - AZS36 can better withstand the corrosive environment of the glass furnace, which can significantly extend the service life of the furnace and reduce the operating cost.

Different parts of the glass furnace have different operating conditions, so the selection of lining materials should be based on the specific application scenarios. For the side wall of the furnace, a material with high corrosion resistance and thermal shock resistance is required. TY - AZS36 is a good choice for the side wall because of its low corrosion rate and high - temperature stability.

The throat of the furnace is a critical area where the flow of molten glass is concentrated. A material with high wear resistance and corrosion resistance is needed. The high - density and low - porosity properties of TY - AZS36 make it suitable for this area. For the electrode sealing area, a material with good electrical insulation and corrosion resistance is required. TY - AZS36 also meets these requirements.

In addition to proper material selection, maintenance is also crucial. Regular inspection of the lining, timely repair of any damage, and proper control of the furnace operating conditions can all help to extend the service life of the lining.

In the context of the upgrading of new material standards in the industry, the selection strategy based on microstructure optimization has become increasingly important. New standards require lining materials to have better performance in terms of corrosion resistance, high - temperature stability, and energy efficiency.

By understanding the microstructure of the lining material, engineers and procurement decision - makers can make more informed choices. For example, they can select materials with a more dense structure, a well - distributed grain boundary, and a high glass - phase precipitation temperature. This can not only improve the performance of the glass furnace but also reduce the environmental impact and operating cost.

As the industry continues to develop, the demand for high - performance glass furnace lining materials will only increase. Therefore, it is essential for manufacturers and users to keep up with the latest trends and adopt the most advanced selection and maintenance strategies.

ISO certification is an important guarantee of product quality. Our TY - AZS36 products have passed the ISO certification, which means they meet the international standards in terms of quality, performance, and safety.

If you are an engineer or a procurement decision - maker in the glass manufacturing industry, and you want to learn more about high - quality electro - fused AZS brick solutions, please visit CTA - URL. We are committed to providing you with the most professional advice and the best products to help you extend the life of your glass furnace and reduce operating costs.