In the glass manufacturing industry, furnace downtime due to side wall failure can cost up to $50,000 per day in lost production — a figure that makes refractory material selection not just an operational choice, but a strategic one.

Common failure modes include erosion from molten glass (especially at temperatures above 1550°C), chemical attack from alkali vapors, and structural degradation from thermal cycling. A recent survey by the International Refractories Association found that over 68% of unplanned shutdowns in flat glass plants were linked to premature refractory wear — with side walls being the most vulnerable zone.

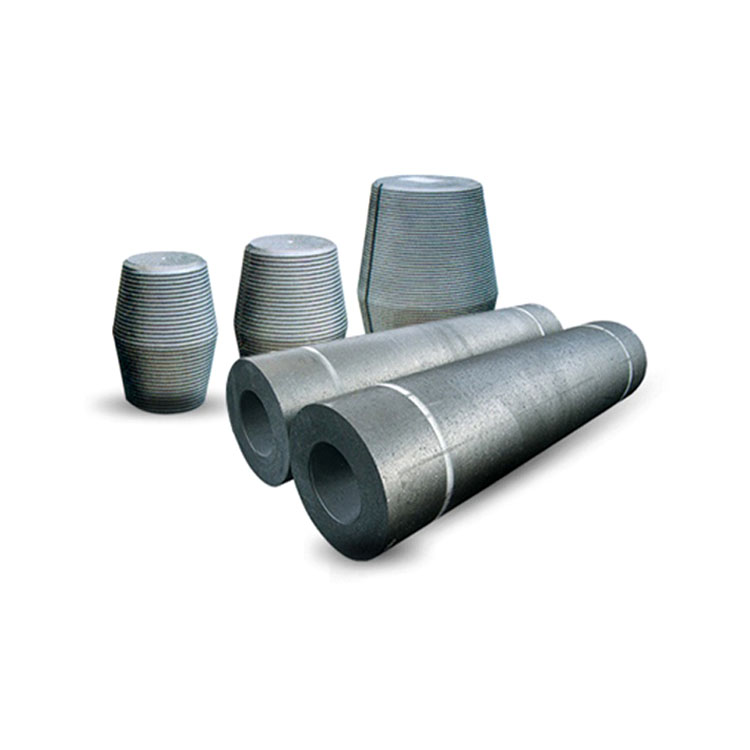

Eletrofused AZS-36 bricks are engineered for extreme conditions. Their key composition includes:

| Component | Typical Content (%) | Function |

|---|---|---|

| Al₂O₃ | 36% | High-temperature stability |

| ZrO₂ | 36% | Corrosion resistance to alkali vapors |

| SiO₂ | 28% | Structural integrity under thermal stress |

These properties translate into real-world performance: AZS-36 shows a cold crushing strength of ≥120 MPa and maintains >95% of its original mass after 24 hours in a 1580°C molten glass environment — significantly outperforming standard fused cast AZS-33 bricks, which typically lose 10–15% of their weight under similar conditions.

Each batch of our Eletrofused AZS-36 is tested against ISO 18788 standards for refractory materials. This ensures consistent quality across global supply chains — critical when sourcing from multiple vendors or managing multi-site operations.

A Tier-1 producer in Belgium replaced traditional AZS bricks with Eletrofused AZS-36 in their side walls. After 18 months of continuous operation, they reported a 40% reduction in maintenance frequency and a 25% increase in furnace run time between relines — directly improving OEE (Overall Equipment Effectiveness).

Download our comprehensive technical manual on Eletrofused AZS-36 applications in glass melting furnaces — complete with lab test results, installation guidelines, and case studies from leading manufacturers worldwide.

Get the Technical Manual Now