The glass industry operates under extreme conditions, with high - temperature environments posing significant challenges to the durability of materials. High - temperature corrosion can lead to equipment damage, reduced production efficiency, and increased maintenance costs. For example, in a glass melting furnace, the lining materials are constantly exposed to high - temperature glass melts and corrosive gases, and traditional materials may show signs of corrosion and wear within a short period, which affects the quality and stability of glass production.

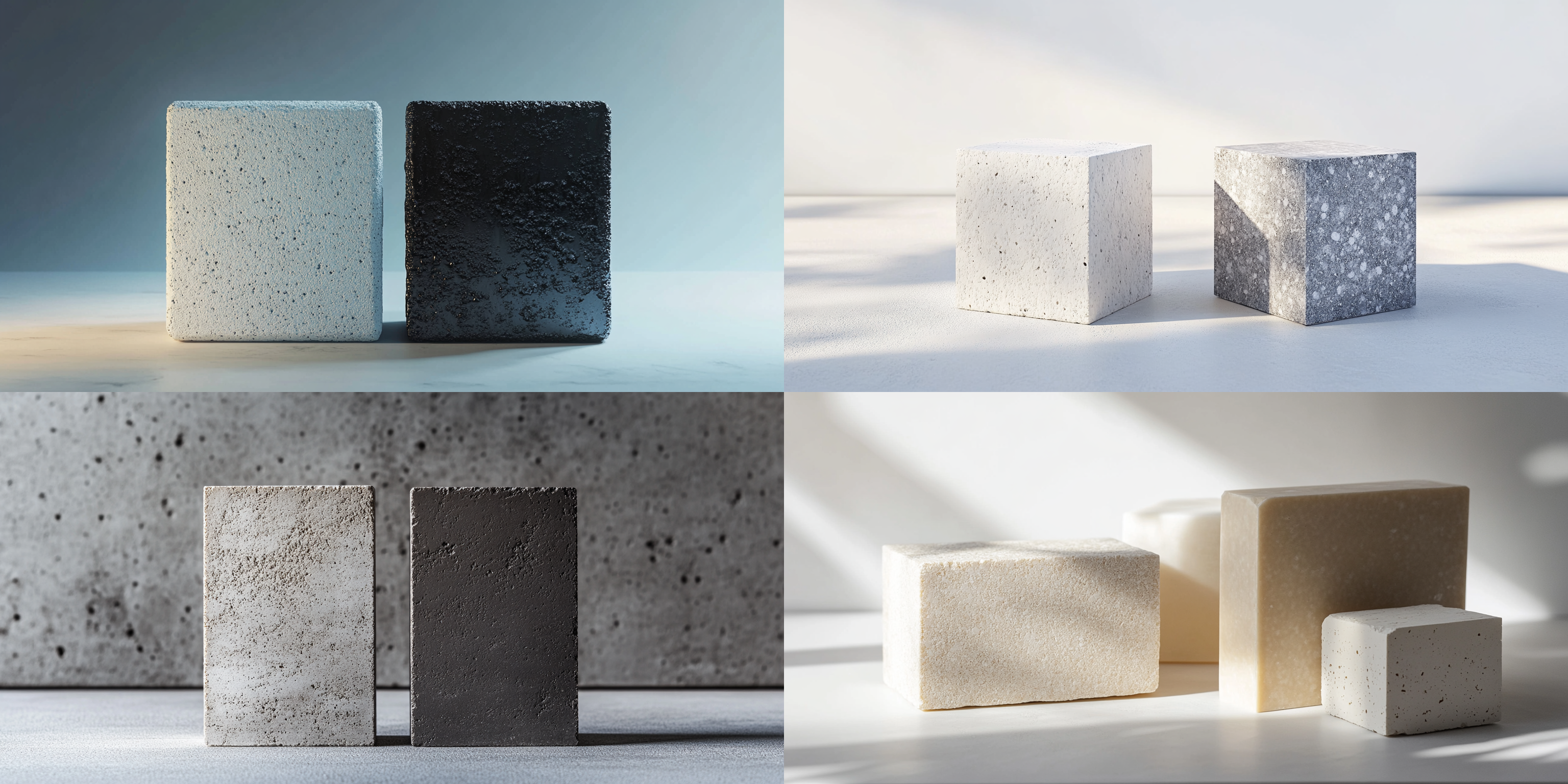

Fused α - β Alumina Brick TY - M is made from high - purity Al₂O₃ as the raw material. The production process involves melting the raw material in an electric furnace at 2000°C. Through this high - temperature melting process, a dense α - β corundum structure is formed. This unique structure endows the brick with excellent physical and chemical properties.

One of the core advantages of Fused α - β Alumina Brick TY - M is its outstanding corrosion resistance below 1350°C. Comparative tests show that compared with ordinary refractory bricks, the corrosion rate of Fused α - β Alumina Brick TY - M in a 1300°C glass melt environment is reduced by 50%. This means that it can maintain its integrity and performance for a longer time in high - temperature and corrosive environments, reducing the frequency of material replacement.

| Material Type | Corrosion Rate at 1300°C (mm/year) |

|---|---|

| Ordinary Refractory Brick | 20 |

| Fused α - β Alumina Brick TY - M | 10 |

A glass manufacturing company used Fused α - β Alumina Brick TY - M in its melting furnace. Before using this product, the furnace needed to be shut down for maintenance every 6 months due to lining material corrosion, and the maintenance cost was approximately $50,000 each time. After using Fused α - β Alumina Brick TY - M, the maintenance interval was extended to 18 months, and the annual maintenance cost was reduced by 60%. At the same time, the production efficiency increased by 15% because of the stable operation of the furnace.

Fused α - β Alumina Brick TY - M has a low pollution characteristic. During the glass production process, it releases very few impurities into the glass melt, which can significantly improve the quality of the glass product. The low - pollution property ensures the stability of the glass melt's chemical composition, reduces the occurrence of defects such as bubbles and inclusions in the glass, and improves the transparency and homogeneity of the glass.

With the continuous development of the glass industry, the demand for high - performance high - temperature corrosion - resistant materials is increasing. Fused α - β Alumina Brick TY - M, with its excellent corrosion resistance, low pollution, and cost - saving features, has broad application prospects in the glass industry. It can help glass manufacturing enterprises achieve efficient and sustainable development.

If you are looking for a high - performance high - temperature corrosion - resistant material for your glass production, Fused α - β Alumina Brick TY - M is definitely worth considering. Click here to learn more about the product's advantages and how it can benefit your business!