Selecting optimal refractory lining materials for high-temperature industrial kilns remains a critical factor in ensuring efficient operation, extended service life, and cost-effective maintenance. Key performance indicators—such as chemical composition, bulk density, porosity, thermal shock resistance, and corrosion endurance—govern material suitability across demanding applications, especially in environments like glass melting furnaces.

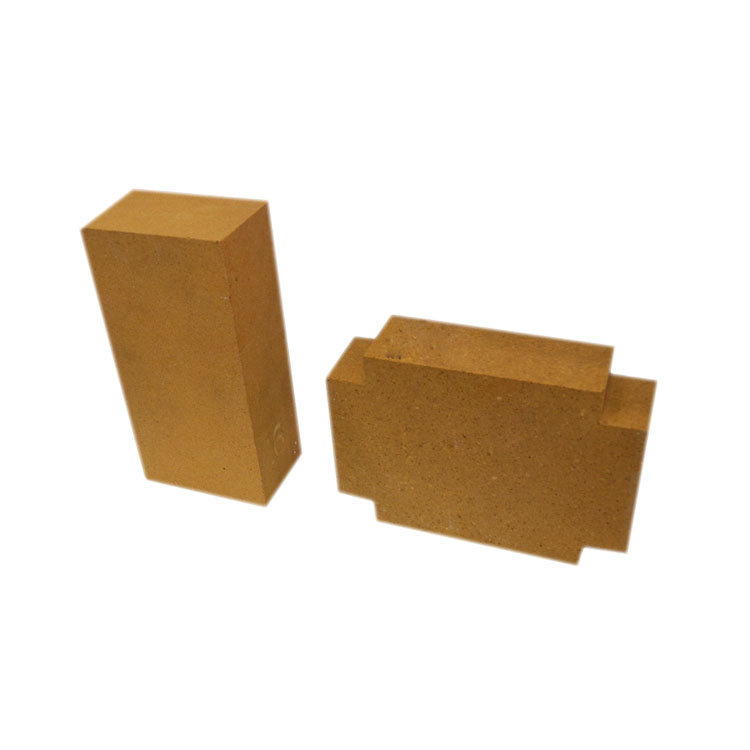

The chemical makeup of refractory materials fundamentally influences their resistance to corrosive slags, molten glass, and high-temperature gases. For instance, electric-fused AZS (Alumina-Zirconia-Silica) bricks, particularly the TY-AZS36 grade, feature a precisely balanced ratio of alumina (~36%), zirconia (~35%), and silica (~29%). This unique blend imparts superior corrosion resistance and mechanical strength, outperforming conventional fireclay or alumina bricks by up to 25% in lifespan under glass furnace conditions.

Bulk density and porosity are interdependent determinants of a refractory’s thermal stability and erosion resistance. High-density bricks exhibit enhanced mechanical strength, with TY-AZS36 reaching up to 3.3 g/cm3, substantially reducing wear. Meanwhile, controlled porosity around 12-15% maintains thermal shock resistance without compromising material integrity, essential for rapid heating cycles common in industrial kiln operations.

| Property | Value (TY-AZS36) | Industry Benchmark |

|---|---|---|

| Bulk Density (g/cm³) | 3.3 | ≥3.0 |

| Porosity (%) | 12-15 | 10-20 |

| Thermal Shock Resistance (cycle count) | ≥20 | ≥15 |

| Corrosion Resistance (weight loss %) | ≤3 | ≤5 |

Such parameter optimization translates to fewer kiln shutdowns and lower refractory consumption—key drivers for process uptime and cost mitigation.

Rapid temperature fluctuations in industrial environments subject kiln linings to intense mechanical stress. The TY-AZS36’s microstructure, characterized by homogeneously dispersed zirconia grains interlaced with alumina and silica matrices, effectively distributes thermal stress. Independent lab tests demonstrate thermal shock cycle counts exceeding 20, a significant improvement compared to standard alumina-based bricks, which often fail below 15 cycles.

Exposure to aggressive molten glasses and chemical slags accelerates refractory degradation. The electric-fused AZS bricks’ unique chemical inertness provides robust resistance to flux infiltration and slag corrosion. Real-world case studies from high-temperature glass melting furnaces show TY-AZS36 outlasting conventional bricks by up to 40%, reducing annual refractory replacement costs by over 15%.

A leading glass manufacturing facility implemented the TY-AZS36 refractory lining in their principal melting furnaces. Within 12 months, operational efficiency improved by an estimated 7%, attributed to reduced energy loss and minimized maintenance frequency. Additionally, users noted a 20% lower incidence of thermal cracking, supporting uninterrupted production cycles and enhancing overall cost efficiency.

For engineers and procurement professionals, balancing upfront refractory costs against long-term operational benefits is essential. Investing in premium electric-fused AZS bricks like TY-AZS36 delivers measurable ROI through extended service life, energy savings, and fewer unplanned downtimes. Comprehensive performance data and industrial benchmarks should guide material sourcing decisions, tailored to specific kiln temperatures, chemical exposure, and mechanical stress profiles.

Interested in upgrading your kiln linings to industry-leading electric-fused AZS bricks? Discover TY-AZS36’s advantages and request a tailored consultation today to maximize your kiln’s durability and operational efficiency.