In the demanding environments of high-temperature ladle operations within the metallurgical industry, the selection of refractory materials is a decisive factor in ensuring optimal performance and longevity. AZS (Alumina-Zirconia-Silica) ladle bricks, renowned for their exceptional corrosion and thermal shock resistance, serve as the cornerstone for maintaining operational reliability in electric arc furnaces and similar high-temperature applications.

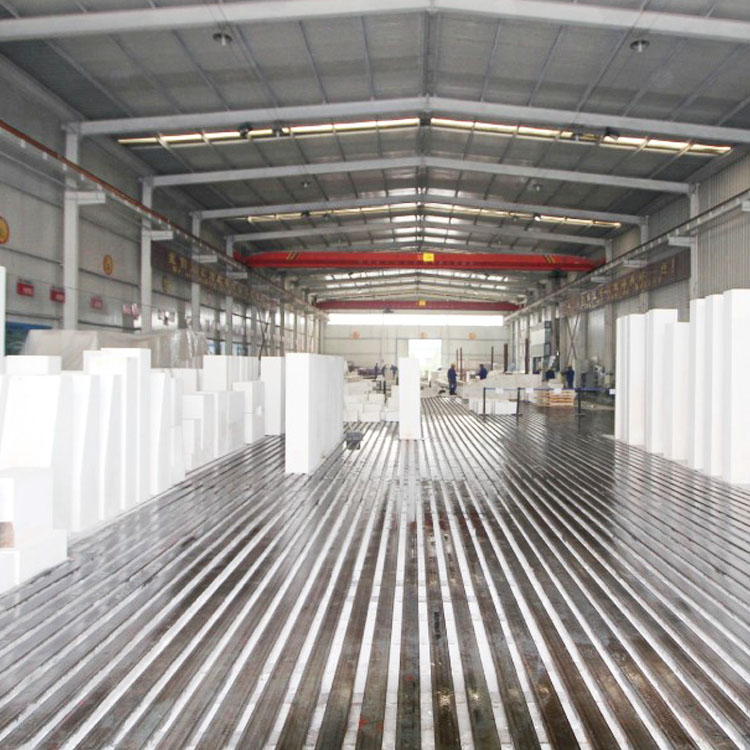

AZS ladle bricks function as the critical interface that withstands molten metal and slag attack. Their manufacturing process involves the melting of a precise mixture of raw materials at temperatures surpassing 1700°C in high-temperature electric furnaces, followed by liquid casting into molds. Upon solidification, the product attains its characteristic vitrified, dense ceramic matrix, ensuring superior durability and structural stability.

The cornerstone of any high-performance AZS ladle brick lies in the purity of its raw materials—high-grade alumina, zirconia, and silica. Impurities such as alkali metals, iron oxides, or other contaminants can significantly impair the melting behavior, crystallization, and ultimately the mechanical strength and corrosion resistance of the final product.

Maintaining raw material purity above 99.8% for alumina and 99.5% for zirconia ensures reproducibility of thermal expansion coefficients and enhances the chemical stability of the bricks in aggressive molten environments, reducing failure rates and downtime.

Proven formulations combining optimized proportions of alumina, zirconia, and silica are developed based on decades of material science research and metallurgical experience. Advanced fused-cast manufacturing technology, including controlled atmosphere melting and precision temperature management, facilitates a dense, homogeneous microstructure with minimal porosity.

Professional technical guidance throughout the production chain further guarantees the product’s consistent quality and enhanced performance under cyclic thermal and chemical stress.

Adherence to ISO standards, particularly ISO 9001 for quality management systems and ISO 14001 for environmental management, acts as an authoritative benchmark for global buyers. Certification confirms rigorous process controls, traceability, and a commitment to continual product improvement—essential assurances for clients relying on AZS ladle bricks in critical and costly metal casting operations.

| Parameter | High-Purity AZS Bricks | Conventional AZS Bricks |

|---|---|---|

| Bulk Density (g/cm³) | 3.45 | 3.25 |

| Cold Crushing Strength (MPa) | >75 | 60 |

| Thermal Shock Resistance (Cycle) | >25 | 15 |

| Corrosion Resistance (mm/year) | 0.3 | 0.6 |

With the global electric arc furnace market forecasted to grow annually by 4.5% over the next five years, demand for superior refractory materials like high-purity AZS ladle bricks is rising steadily. End-users prioritize durability, energy efficiency, and reduced maintenance costs—in areas where these bricks prove their unmatched value.

“Since switching to these high-purity AZS ladle bricks, we have experienced a 30% increase in service life and a notable reduction in unscheduled furnace downtimes. Their consistent quality and the manufacturer’s technical support have been invaluable to our operations.”

— Global Steel Producer, Europe

For procurement specialists and industry managers committed to optimizing refractory solutions, selecting AZS ladle bricks manufactured from high-purity raw materials represents an investment in operational excellence and long-term cost-effectiveness. Detailed technical data sheets, sample testing, and customized solutions are available upon request.