In the glass manufacturing industry, wear resistance in high-temperature zones is not just a technical detail—it’s a direct cost driver. If you're managing a melting furnace, understanding how electrically fused AZS (Al₂O₃-ZrO₂-SiO₂) cast blocks work under extreme conditions can help you avoid costly downtime and extend your equipment life by up to 40%.

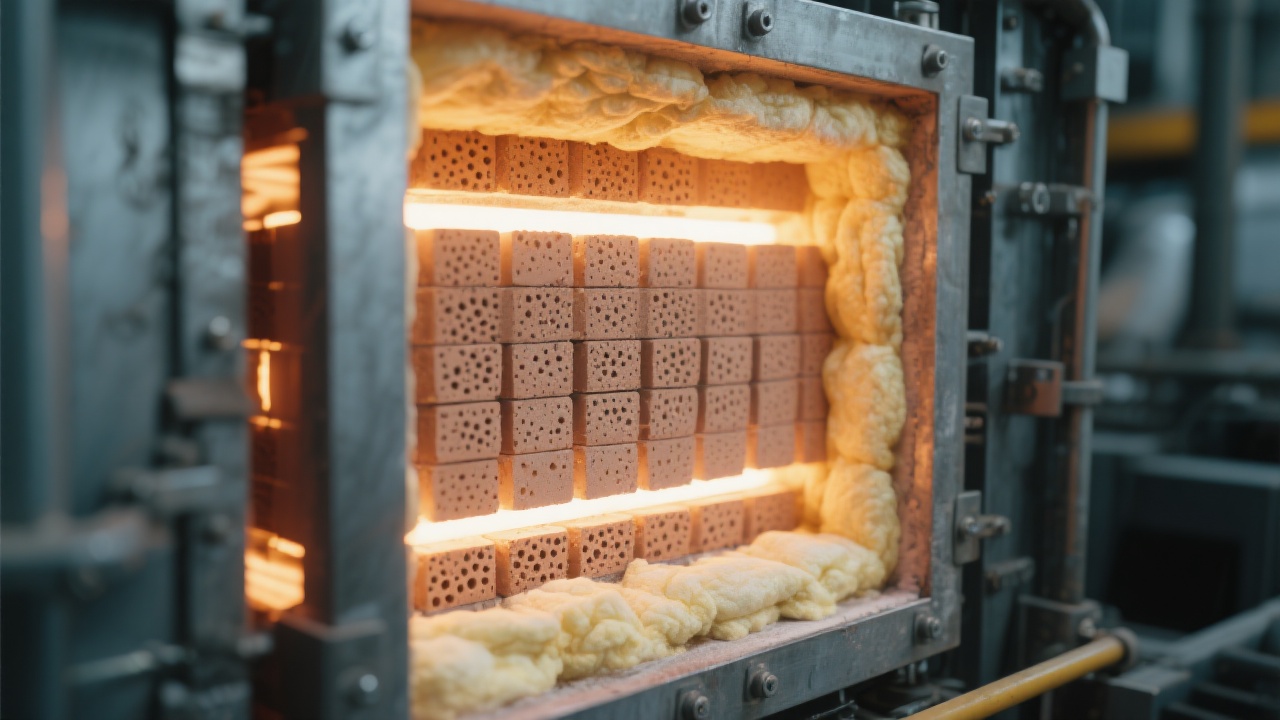

The key lies in the dense, uniform microstructure formed during electric fusion. Unlike sintered bricks, which have pores and grain boundaries that act as weak points, AZS blocks develop a continuous crystalline network at temperatures above 1700°C. This structure resists thermal shock, chemical attack from molten glass (especially alkali-rich melts), and mechanical abrasion—critical factors when lining the upper structure or side walls of your furnace.

You may see various grades like 33#, 36#, or 41#. But here's what matters: 33# AZS contains ~33% Al₂O₃, ~23% ZrO₂, and ~44% SiO₂. This ratio creates optimal phase balance—enough zirconia for refractoriness (>1750°C), enough alumina for strength, and sufficient silica to reduce thermal expansion mismatch with molten glass. In real-world applications across Europe and Southeast Asia, this grade consistently outperforms others in both longevity and reliability.

| Grade | Typical Use Case | Avg. Service Life (Months) |

|---|---|---|

| 33# AZS | Upper wall, side wall, feed channel | 24–36 |

| 36# AZS | High-alkali areas, crown | 18–28 |

| 41# AZS | Specialized corrosion zones | 12–20 |

“Before switching to 33# AZS blocks, our feed channel would clog every 3–4 months due to crystallization. After proper installation and using the correct joint design, we saw zero blockages for over 10 months — and our maintenance team reported a 35% drop in labor hours.”

— Miguel Torres, Plant Manager, VetroTech Spain

Even the best material fails if installed incorrectly. Here are the top 3 mistakes we’ve seen:

Follow our step-by-step guide: preheat slowly (≤100°C/hr), use phosphate-based mortar (not cement!), and install blocks with precise joint gaps of 3–5 mm. These small steps translate into up to 30% lower maintenance frequency and longer service intervals.

If you’re still using older refractory materials or facing frequent repairs, it’s time to upgrade. We’ve helped over 30 glass plants globally reduce operating costs through smarter AZS selection and structured maintenance planning.