As a critical component in the glass manufacturing process, the melting furnace is constantly exposed to extreme temperatures and corrosive environments. Over time, this leads to issues such as corrosion, thermal stress, and structural degradation, which significantly reduce the lifespan of the furnace and increase maintenance costs. To address these challenges, many glass manufacturers are turning to advanced refractory materials like AZS33, which offer superior performance and long-term reliability.

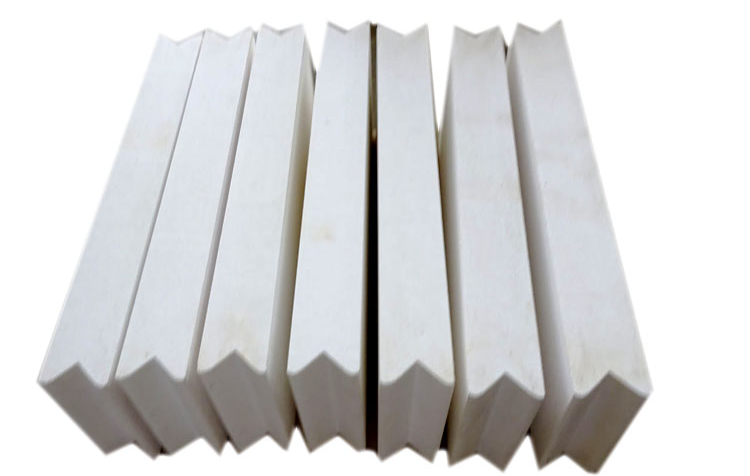

AZS33 is a high-performance fused zirconia-alumina-silica (AZS) material, specifically designed for use in glass melting furnaces. It is composed of approximately 33% zirconium oxide (ZrO₂), 47% aluminum oxide (Al₂O₃), and 20% silicon dioxide (SiO₂). This unique composition provides excellent resistance to chemical attack from molten glass and maintains structural integrity under high-temperature conditions.

The exceptional durability of AZS33 stems from its dense microstructure, formed through an advanced fusion process that minimizes porosity and enhances mechanical strength. This structure significantly improves the material's resistance to penetration by molten glass, reducing wear and extending the service life of furnace components.

Compared to conventional refractories, AZS33 demonstrates a reduction in corrosion rate by up to 40%, according to field tests conducted by leading glass producers. This makes it particularly suitable for high-temperature zones where glass melt interacts directly with the refractory lining.

AZS33 is widely used in critical areas of the glass melting furnace, including:

Several glass manufacturing companies have reported significant improvements after switching to AZS33. For example, one major producer in Europe saw a 30% increase in furnace operational life and a 25% reduction in downtime due to refractory failure. Another case study from Asia showed a 15% improvement in product quality, attributed to the consistent thermal properties of AZS33.

| Application Area | Performance Improvement |

|---|---|

| Combustion Zone | Reduction in corrosion by 40% |

| Bottom Lining | Extended service life by 30% |

| Side Walls | Improved thermal stability by 20% |

AZS33 material offers a scientifically validated solution for enhancing the performance and longevity of glass melting furnaces. Its unique composition, dense microstructure, and proven application results make it an ideal choice for manufacturers seeking to improve efficiency, reduce maintenance, and ensure consistent product quality.

For those looking to optimize their production processes and achieve long-term cost savings, AZS33 is a key investment. Explore our full range of refractory solutions today and take your glass manufacturing operations to the next level.