When selecting refractory materials for high-temperature industrial kilns, understanding the critical performance metrics is paramount. The chemical composition, bulk density, porosity, thermal shock resistance, and corrosion resistance intricately influence the durability and efficiency of kiln linings. These attributes not only determine how well the material withstands extreme thermal cycling but also how it resists chemical degradation from process gases and molten materials.

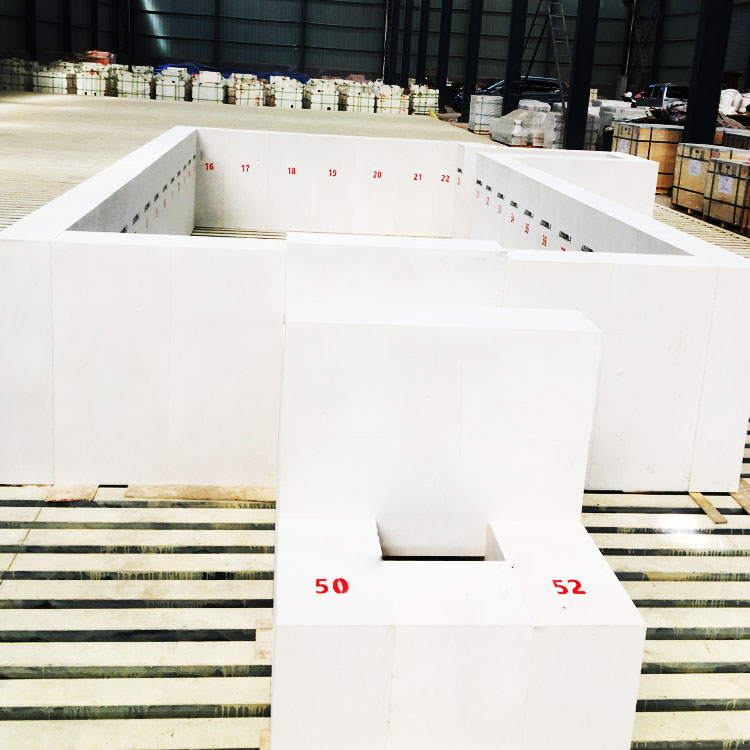

For example, electrical fused AZS (Alumina-Zirconia-Silica) bricks, such as the TY-AZS36 variant, exhibit excellent thermal stability and corrosion resistance. Their microstructure, featuring low porosity around 16% and a bulk density close to 3.0 g/cm³, ensures minimal gaseous infiltration and maximal structural integrity. This composition supports resistance to alkali and molten glass corrosion, making them particularly suitable for glass melting furnaces' sidewalls and throat areas.

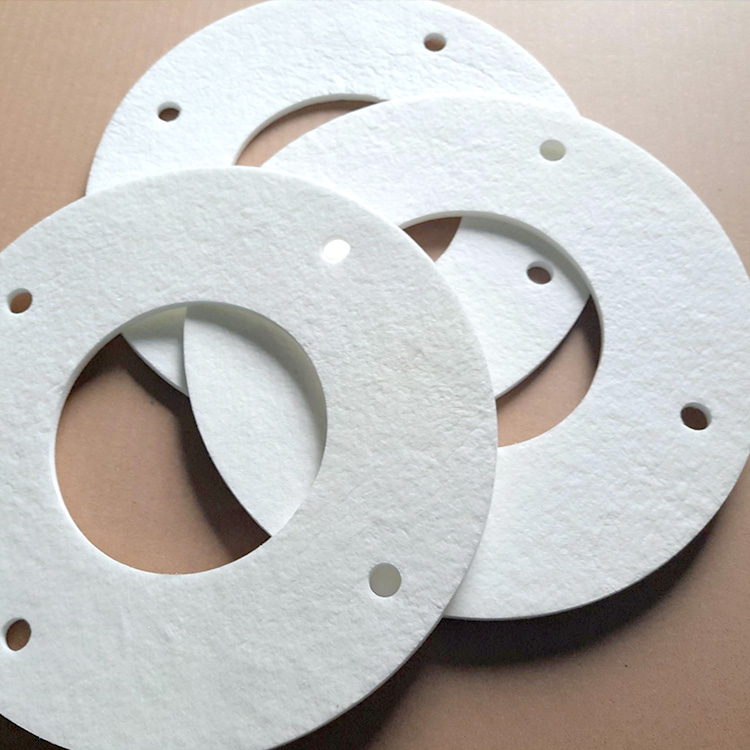

AZS bricks generally comprise roughly 70% alumina, 25% zirconia, and 5% silica, optimizing mechanical strength and chemical inertness. The cubic zirconia dispersed within the alumina matrix acts as a thermal expansion buffer, enhancing thermal shock resistance significantly. Microstructural analyses reveal uniform grain distribution and limited pore connectivity, which diminishes pathways for corrosive agents.

Industry studies have demonstrated that even a minor increase in open porosity from 10% to 20% can reduce thermal shock resistance by up to 25%. Thus, maintaining tight control on manufacturing parameters directly influences service life extension.

Thermal shock damage remains a leading cause of premature failure in refractory linings. Electrical fused AZS bricks like TY-AZS36 withstand over 30 cycles of rapid heating and cooling between room temperature and 1500°C before microcracking initiates, outperforming conventional fireclay bricks which may fail within 10 cycles.

Mitigating thermal shock failure requires both material selection and kiln operation optimization. Preheating protocols, controlled atmosphere, and gradual temperature ramp-up during startup phases are recommended techniques. Engineers should additionally consider composite lining strategies—pairing high thermal shock resistant bricks in critical zones with more economical materials elsewhere.

Corrosive degradation caused by molten glass and alkali vapors compromises kiln lining integrity and operational efficiency. The specialized chemical makeup of TY-AZS36 bricks provides robust resistance to these aggressive agents. Their high zirconia content improves crystalline stability, limiting reactions with molten glass components such as Na2O and K2O.

Field data from a glass manufacturing facility indicated a 40% reduction in refractory replacement downtime after transitioning to TY-AZS36 linings, with corrosion penetration depths decreasing from 15 mm to under 5 mm after 12 months of continuous operation. Such results underline the economic benefits of investing in premium lining materials.

| Parameter | TY-AZS36 Value | Industry Average |

|---|---|---|

| Bulk Density (g/cm³) | 3.0 | 2.8 - 3.1 |

| Porosity (%) | 16 | 15 - 20 |

| Thermal Shock Resistance (cycles) | >30 | <15 |

| Corrosion Resistance (penetration mm) | <5 | 10-15 |

At a leading glass manufacturer, the installation of TY-AZS36 electrical fused AZS bricks in the melting furnace’s sidewalls and throat areas yielded notable improvements. Prior challenges with frequent refractory failures due to alkali corrosion and thermal shock were mitigated, resulting in a 20% increase in average campaign life. Operational costs declined by reducing unscheduled outages and refractory replacements.

Additionally, precise quality control during brick manufacturing ensured dimensional stability and installation accuracy, minimizing cold joints and heat loss. Together with proper kiln maintenance protocols, including periodic inspections and hot repairs, the durability of the lining system was further enhanced.

Choosing the best refractory lining requires a thorough assessment of process conditions including maximum operating temperature, atmosphere composition, and thermal cycling frequency. Experts recommend conducting initial testing under simulated kiln environments to evaluate candidate materials’ behavior.

Combining scientific material selection with operational best practices ensures that industrial kilns achieve maximum uptime, energy efficiency, and cost-effectiveness.