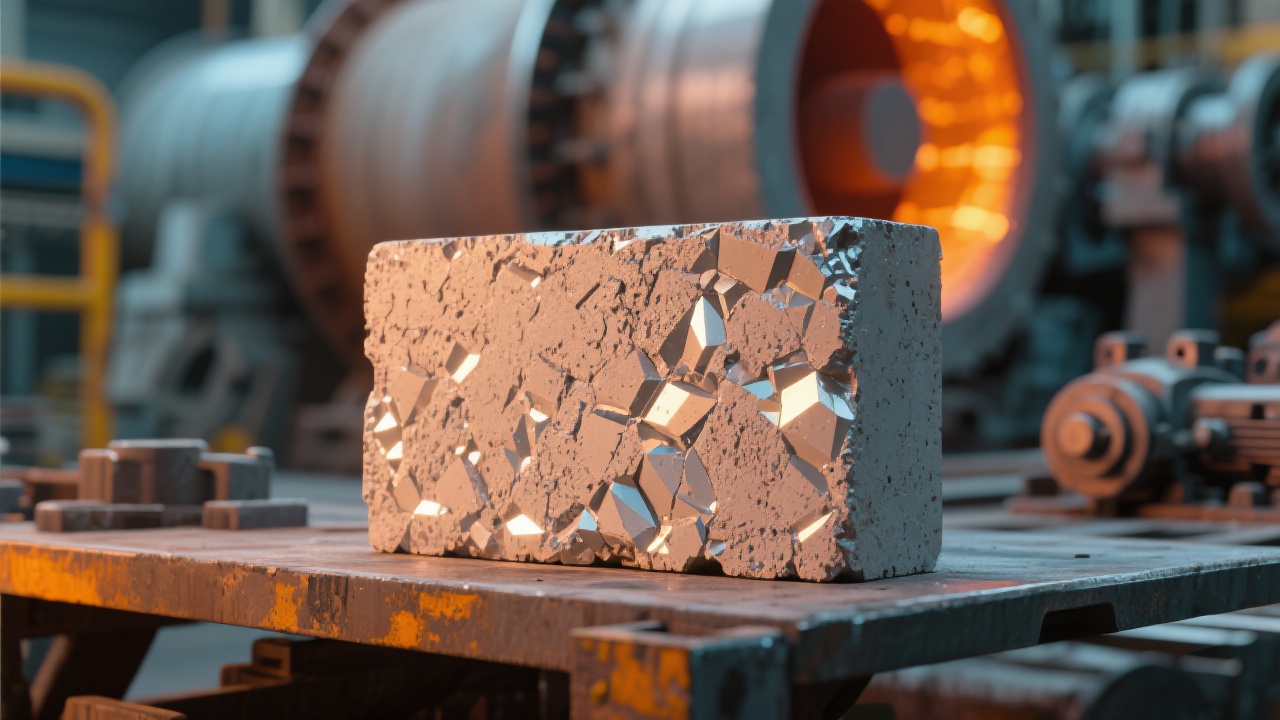

Fused AZS cast blocks are mainly composed of Al2O3-ZrO2-SiO2. This unique chemical composition forms a dense structure during the melting and casting process. The dense structure endows the product with excellent physical and chemical stability under extreme conditions. For example, at high temperatures up to 1500°C, the material can maintain its structural integrity, with a strength loss of less than 10% compared to room temperature, which is far superior to many ordinary refractory materials.

In glass melting furnaces, the materials are often subject to the scouring of high - temperature glass liquid. Fused AZS cast blocks have extremely high hardness, and their wear rate in high - temperature glass liquid can be controlled within 0.1mm/year, effectively protecting the furnace structure and reducing the wear caused by the flowing glass liquid.

During the operation of the glass melting furnace, the temperature changes frequently. Fused AZS cast blocks can withstand rapid temperature changes from 200°C to 1500°C without cracking. Through experimental tests, it can withstand more than 1000 thermal shock cycles, ensuring the long - term stable operation of the furnace.

The chemical substances in the glass melting process, such as alkalis and acids, have strong corrosive effects on materials. Fused AZS cast blocks show excellent chemical corrosion resistance. In a strong alkali environment, its corrosion rate is less than 0.05mm/year, greatly extending the service life of the furnace.

Fused AZS cast blocks have a wide range of applications in different areas of glass melting furnaces. In the upper structure of the furnace, they can resist high - temperature flue gas erosion; in the side walls, they can withstand the scouring of high - temperature glass liquid; in the charging channel, they can ensure the smooth flow of raw materials without being easily worn or corroded. The following table shows the application effects in some key areas:

| Application Area | Advantages | Maintenance Points |

|---|---|---|

| Working Pool Side Wall | Resist the scouring of high - temperature glass liquid, reduce wear | Regularly check the wear degree, and repair or replace in time |

| C - shaped Brick | Ensure the structural stability of the furnace, resist high - temperature deformation | Check the connection parts regularly to prevent loosening |

| Trough Bottom | Resist the corrosion of glass liquid, extend the service life of the trough | Keep the bottom clean, prevent the accumulation of impurities |

Proper installation and maintenance are crucial for the performance of fused AZS cast blocks. During installation, it is necessary to ensure accurate positioning and tight connection to avoid gaps that may cause leakage or damage. In daily maintenance, regular inspections should be carried out, including checking for cracks, wear, and corrosion. According to engineering experience, regular maintenance can extend the service life of the product by more than 30%.

With the continuous development of the glass industry, the requirements for refractory materials are also increasing. We are committed to continuous innovation, constantly improving the performance of fused AZS cast blocks, and adapting to new industry requirements. For example, we are researching new production processes to further improve the density and performance of the material.

In conclusion, fused AZS cast blocks have excellent performance and broad application prospects in glass melting furnaces. They can effectively improve the efficiency of glass production, extend the service life of the furnace, and reduce maintenance costs. If you want to learn more about our high - performance fused AZS cast blocks and how they can bring value to your glass manufacturing business, click here to explore now!