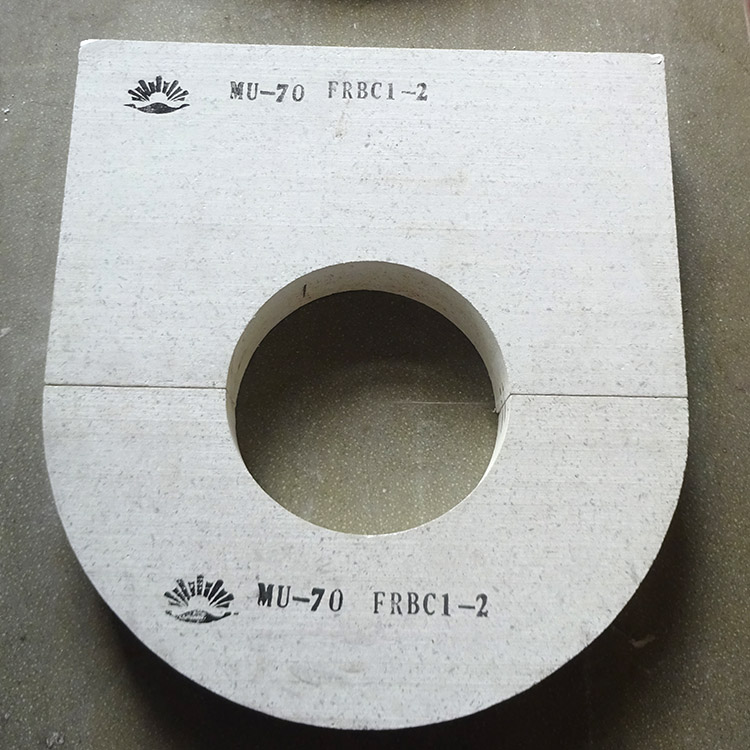

In the global glass industry, the demand for high-quality refractory materials is ever - increasing. The quality of refractory materials directly impacts the efficiency and quality of glass production. Against this backdrop, the AZS rotary tube bricks produced by our company have emerged as a reliable solution, especially with the support of ISO certification.

Our AZS rotary tube bricks possess a series of remarkable quality characteristics. Firstly, they have excellent fire - resistance. With a melting point of up to 1800°C, they can withstand the extremely high temperatures in glass furnaces without significant deformation or damage. This high - temperature resistance ensures a long service life in harsh working environments.

Secondly, their thermal stability is impressive. These bricks can endure rapid temperature changes without cracking. Tests have shown that they can withstand temperature fluctuations of up to 200°C per hour, which is crucial in the glass - making process where temperature adjustments are frequent.

In addition, the AZS rotary tube bricks have strong resistance to corrosion by molten glass. The corrosion rate in contact with common glass melts is as low as 0.1mm per year, effectively protecting the furnace lining and minimizing the pollution of molten glass. Their anti - peeling performance is also excellent, which helps maintain the integrity of the furnace structure and ensures the stability of the glass - making process.

Our company has obtained ISO certification, which is a testament to our strict quality control system. We adhere to international standards throughout the production process. From the selection of raw materials to the final product inspection, every step is carefully monitored. Our advanced production technology ensures the consistency and high quality of each AZS rotary tube brick.

For example, we use a special high - pressure molding process, which makes the internal structure of the bricks more compact and uniform. This process not only enhances the physical properties of the bricks but also improves their chemical stability.

We understand that different glass manufacturers may have different requirements. Therefore, we offer customized services. Whether it is the size, shape, or performance parameters of the AZS rotary tube bricks, we can tailor - make products according to the specific needs of customers.

Many well - known glass companies around the world have chosen our AZS rotary tube bricks. For instance, a large - scale glass manufacturer in Europe reported that after using our products, the service life of their glass furnaces increased by 30%, and the defect rate of glass products decreased by 20%. Another glass factory in Asia said that the use of our AZS rotary tube bricks significantly reduced the pollution of molten glass, improving the clarity and quality of the final glass products.

With ISO certification and strict quality control, our AZS rotary tube bricks are a reliable choice for your glass production. Their high fire - resistance, excellent thermal stability, strong corrosion resistance, and good anti - peeling performance can effectively improve the quality and efficiency of glass production. The customization service can meet your specific needs.

If you are looking for high - quality refractory materials for your glass production, our AZS rotary tube bricks are the ideal solution. Contact us today to learn more about our products and how they can benefit your business. Our professional team is ready to provide you with detailed information and support.