.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

In industries requiring robust and reliable refractory linings, such as steelmaking and non-ferrous metal production, high-temperature ladles operate under extreme thermal and chemical stresses. The integrity and longevity of refractory materials directly influence operational efficiency, maintenance costs, and product quality. Among various refractory solutions, AZS (Alumina-Zirconia-Silica) fireclay bricks stand out as premium materials engineered to meet these demands with exceptional performance.

.jpg)

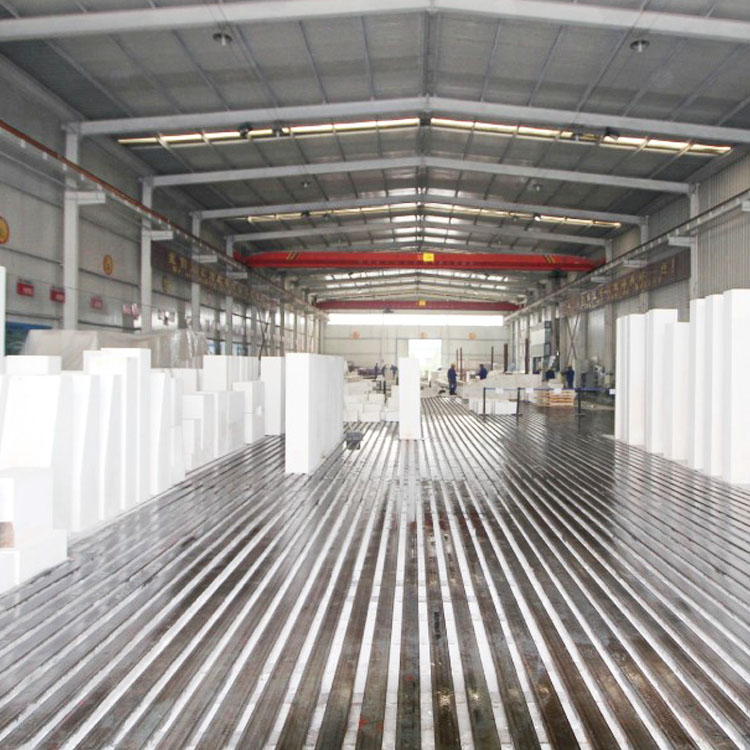

The production of AZS fireclay bricks involves a meticulously controlled process, starting with the melting of high-purity raw materials in electric furnaces at temperatures reaching approximately 1700°C. The homogeneous molten mixture is then poured in liquid form into precision-engineered molds where it solidifies, forming a dense and uniform ceramic bonding matrix. This fused-cast process not only guarantees exceptional chemical stability and mechanical strength but also provides resistance against corrosion from molten glass and alkaline slags.

Key manufacturing stages and their significance:

| Stage | Description | Quality Impact |

|---|---|---|

| High-Purity Raw Material Selection | Use of top-grade alumina, zirconia, and silica ores | Ensures chemical inertness and minimizes impurity-induced degradation |

| Electric Furnace Melting | Homogeneous fusion of raw materials into a molten state | Creates uniform crystal structure, enhancing mechanical performance |

| Liquid Casting into Molds | Controlled cooling to form dense ceramic matrix | Prevents porosity, improves slag resistance, and structural integrity |

| Quality Inspection and Technical Guidance | Expert monitoring throughout production and post-manufacturing | Ensures consistent output aligned with industry standards |

The hallmark of excellence in refractory manufacturing, ISO 9001 certification verifies stringent quality management systems and consistency in product delivery. AZS fireclay bricks bearing this certification signal to global buyers that rigorous control procedures are embedded at every stage — from raw material procurement to finished product evaluation.

This internationally recognized standard is especially critical for industries where safety, durability, and performance cannot be compromised. For procurement managers, engaging suppliers with ISO-certification substantially mitigates risk linked to refractory failures and unplanned downtime.

When benchmarked against standard fireclay or mullite bricks, AZS fireclay bricks showcase multiple advantages:

The refractory industry is growing steadily at an approximate CAGR of 5%, propelled by the expansion of steel and glass manufacturing globally. Demand for highly specialized refractory bricks like AZS is rising, especially in regions focusing on energy efficiency and sustainable production.

Industry leaders have expressed confidence: a major steel producer recently noted, “Since switching to ISO-certified AZS bricks, our ladle maintenance intervals have extended by 25%, reducing downtime and costs significantly.” Another customer highlighted improved product consistency, stating that “the uniformity and corrosion resistance of AZS bricks are unmatched compared to previous materials.”

The fusion of premium raw materials, stringent manufacturing protocols, and ISO international certification culminates in AZS fireclay bricks offering exceptional resistance to temperature extremes, chemical attack, and mechanical wear. These qualities translate into reduced operational costs and enhanced safety for high-temperature ladle applications worldwide.

For procurement professionals seeking reliable refractory solutions with a verified quality promise, AZS bricks represent a prudent investment in longevity and performance.