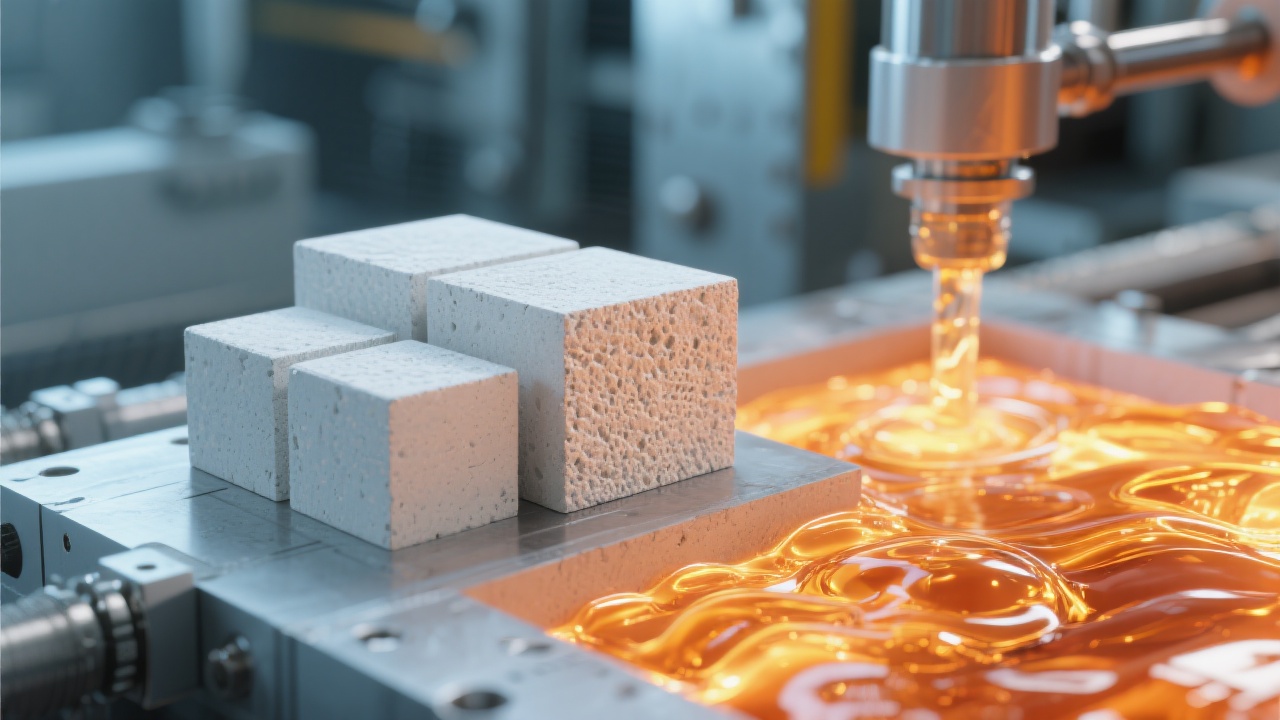

In the operation of float glass furnaces, the corrosion resistance of refractories directly determines the production stability and glass quality. This article delves into how low-sodium fused AZS refractories, such as TY - AZS36D, enhance the stability of the glass phase and inhibit crystal precipitation by controlling the Na₂O content (≤1.35%), thereby significantly extending the furnace life and reducing glass defects.

The structure of the glass phase in refractories is crucial for the performance of float glass furnaces. High Na₂O content can lead to unstable glass phase structures, which may cause crystal precipitation and reduce the corrosion resistance of refractories. For example, when the Na₂O content exceeds 1.35%, the glass phase tends to crystallize more easily under high - temperature conditions in the furnace, resulting in the deterioration of refractory performance.

Let's take a look at some real - world data. In a large - scale float glass production line, the original refractory materials with higher Na₂O content had an average furnace life of about 4 - 5 years. After replacing them with low - sodium fused AZS refractories like TY - AZS36D, the furnace life was extended to 6 - 7 years. This is because the low - sodium formulation effectively stabilizes the glass phase, reducing the damage caused by corrosion and crystallization.

One of our customers, a well - known glass manufacturer in Europe, reported a significant reduction in glass defects after using TY - AZS36D in their float glass furnace. The defect rate decreased from about 3% to less than 1%, which not only improved the glass quality but also increased the production efficiency.

The performance indicators of low - sodium fused AZS refractories are closely related to their usage scenarios. For example, in the key parts of float glass furnaces, materials with Al₂O₃ ≥ 50% and ZrO₂ ≥ 35.5% are required. These high - content components endow the refractories with excellent corrosion resistance and high - temperature stability.

The apparent porosity of ≤2% also plays a vital role. A lower apparent porosity means less penetration of corrosive substances, which is crucial for maintaining the long - term performance of refractories in harsh furnace environments. Different parts of the float glass furnace, such as the melting zone and the throat, have different requirements for refractory materials. Based on the glass composition, temperature gradient, and operation cycle, we can select the most suitable low - sodium fused AZS refractories.

TY - AZS36D has passed ISO certification, which is a testament to its high - quality production process and stable performance. Moreover, it has been verified through long - term overseas cooperation. We have served customers in more than 30 countries around the world, and their positive feedback shows the reliability of TY - AZS36D.

For technical personnel in charge of procurement, process control, and equipment maintenance, making the right choice of refractories is a challenging task. We provide a scientific selection guide based on the glass composition, temperature gradient, and operation cycle of the float glass furnace. By referring to this guide, they can make more efficient and economical decisions.

For example, if the glass contains a high proportion of alkaline substances, a low - sodium fused AZS refractory with a higher Al₂O₃ content may be more suitable. If the furnace operates at a very high temperature for a long time, a material with better high - temperature stability and lower apparent porosity should be selected.

In conclusion, low - sodium fused AZS refractories, especially TY - AZS36D, offer significant advantages in float glass furnace applications. They can effectively solve the technical selection pain points of float glass furnace lining materials. By choosing our products, you will never be disappointed. We are committed to helping you extend the furnace life, reduce glass defects, and improve production efficiency.