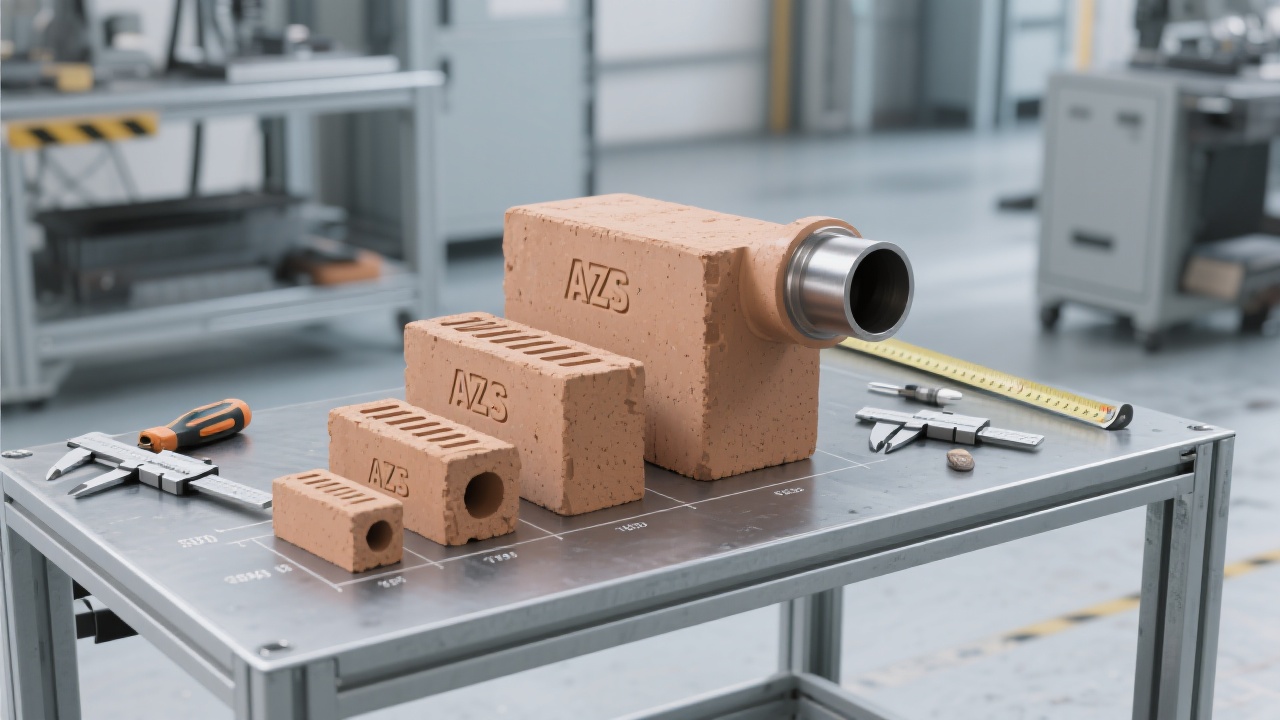

In the demanding environment of glass production, where temperatures exceed 1,600°C and chemical erosion is constant, the choice of refractory materials directly impacts furnace efficiency, safety, and lifecycle costs. Among these, electric-fused Al₂O₃–ZrO₂–SiO₂ (AZS) castables stand out—not just for their composition, but for how that composition translates into real-world performance.

The key to AZS’s effectiveness lies in its microstructure—a dense, interlocking network formed during high-temperature fusion. Studies show that an optimal ratio of 41% Al₂O₃, 35% ZrO₂, and 24% SiO₂ creates a phase-stable matrix with minimal porosity (<0.5%) and exceptional thermal shock resistance. This structure allows it to withstand over 1,000 thermal cycles without cracking—far surpassing conventional fireclay bricks, which typically fail after 300–500 cycles.

Moreover, ZrO₂ acts as a toughening agent by transforming from monoclinic to tetragonal phase under stress, absorbing energy and preventing crack propagation. In lab tests, AZS samples exhibited a flexural strength of up to 75 MPa at 1,500°C—more than double that of standard zirconia-alumina composites.

| Property | AZS Castable | Standard Refractory |

|---|---|---|

| Thermal Shock Resistance (cycles @1500°C) | >1,000 | ~400 |

| Wear Rate (mm³/cm²·hr) | 0.08 | 0.35 |

| Chemical Stability (in molten glass) | Excellent | Moderate |

A leading manufacturer in Belgium replaced traditional refractories in their upper melter wall and feed channel with electric-fused AZS blocks. After 18 months of continuous operation, they reported:

These improvements weren’t accidental—they were driven by precise installation practices and regular monitoring, both critical to maximizing performance. For instance, maintaining a uniform gap between blocks (≤2 mm) and using ceramic fiber insulation beneath them reduced thermal stress by up to 40%, according to field data from our R&D team.

Whether you’re designing a new furnace or optimizing an existing one, understanding how material science meets operational reality is essential. The right refractory isn’t just about durability—it’s about reducing total cost of ownership while ensuring consistent product quality.

If your plant faces frequent refractory degradation or wants to extend equipment life without compromising output, we invite you to explore how our engineered AZS solutions can deliver measurable results. Let’s talk about what’s possible—for your next project, and beyond.

Get Your Customized Refractory Assessment Today