In the demanding environment of float glass furnaces, the sustainability and performance of refractory linings directly impact both product quality and the operational lifespan of critical equipment. Among the key factors influencing refractory material durability, the sodium oxide (Na₂O) content plays a pivotal role in maintaining glass phase stability and improving anti-crystallization ability. This article delves into how controlling Na₂O levels to below 1.35% significantly enhances refractory corrosion resistance and extends service life—offering vital insights to technical teams and purchasing decision-makers aiming to optimize material selection, reduce downtime risks, and control maintenance expenditure.

The refractory lining of a float glass furnace endures aggressive chemical assaults and extreme thermal cycles, making its structural stability paramount. Instability within the refractory matrix often induces crystallization, which compromises the material’s protective role, leading to increased corrosion and mechanical failure. A stable glass phase within the refractory prevents the formation of secondary crystalline phases that are brittle and prone to spalling. Hence, understanding and controlling compositional factors, particularly Na₂O content, is essential for maintaining integrity under furnace conditions.

Sodium oxide acts as a flux agent in refractory compositions, affecting viscosity and melting behavior of the glass phase. Elevated Na₂O content generally lowers the melting point but also promotes devitrification—resulting in crystallization and weakening of the refractory structure. Conversely, reducing Na₂O to ≤1.35% stabilizes the glass phase by maintaining an optimal network former-to-modifier ratio, which suppresses nucleation and growth of unwanted crystals.

Chemically, lower sodium levels reduce alkali–silica interactions which mitigate corrosive attack by molten glass batches rich in sodium. Physically, this results in enhanced resistance against crystallization-related embrittlement and surface scale formation that accelerate lining degradation.

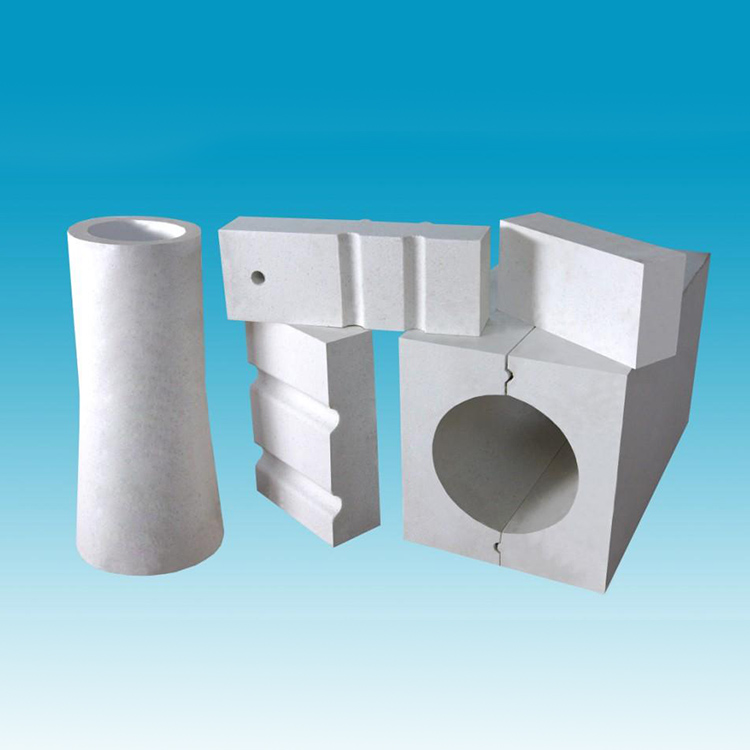

The TY-AZS36D refractory material, compliant with electric fusion AZS standards, employs a low sodium oxide formulation that has demonstrated remarkable performance improvements:

Optimal refractory selection requires a nuanced approach that aligns Na₂O levels with specific glass compositions, temperature gradients, and operational cycles. For instance:

Such strategic selection approaches reduce furnace downtime, minimize unplanned shutdown risks, and support overall operational efficiency.

The direct implications of using low Na₂O refractory products like TY-AZS36D translate into measurable cost savings and operational efficiencies:

Implementing these scientific insights fosters a competitive advantage for float glass manufacturers targeting both quality and sustainability.

Contact our expert team today for personalized technical support and access detailed product documentation to elevate your float glass production.