Fused AZS refractory materials play a crucial role in the glass industry, especially in high - temperature kilns. Understanding their core process and technical details is essential for both engineering technicians and procurement decision - makers.

The quality of raw materials is the foundation of high - performance fused AZS refractory materials. High - purity raw materials are selected to ensure the basic properties of the final product. For example, the selection of alumina, zirconia, and silica should meet strict purity standards. Generally, the alumina content should be above 95%, zirconia around 30%, and silica about 5% - 10%. The proportioning of these raw materials follows the principle of achieving the best chemical and physical properties. A proper ratio can optimize the crystal structure and glass - phase composition of the refractory material.

The electric furnace melting process is a critical step in the production of fused AZS refractory materials. Precise control of temperature, time, and power is required. The melting temperature usually ranges from 1800°C to 2000°C. Maintaining a stable temperature is crucial for ensuring the uniformity of the molten liquid. The melting time is also carefully controlled, typically around 8 - 12 hours, depending on the furnace capacity and raw material characteristics. During the melting process, the oxidation process has a significant impact on the Na2O/K2O content. By optimizing the oxidation process, the Na2O/K2O content can be reduced from about 2% to less than 1%. This reduction in Na2O/K2O content can improve the stability of the glass - phase structure.

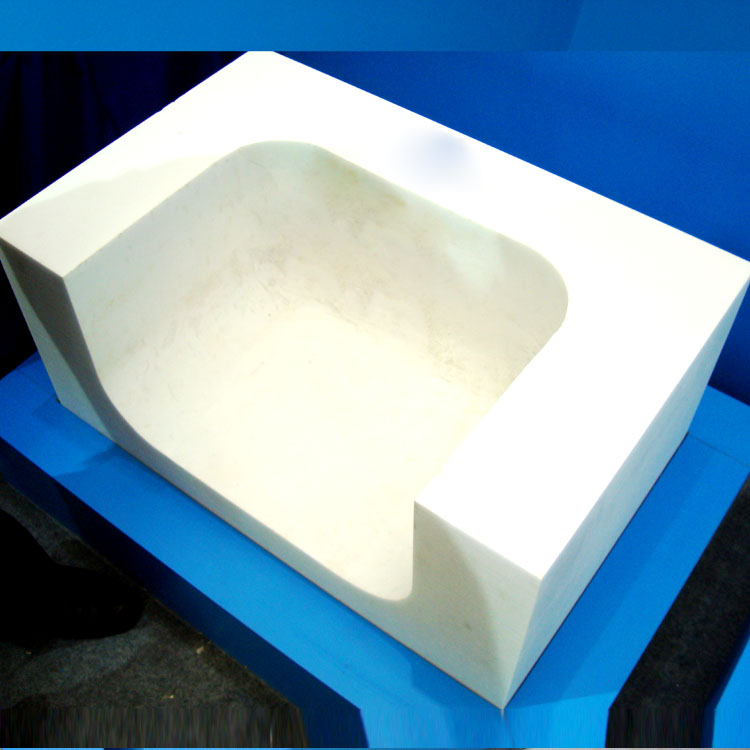

After melting, the liquid is poured into a mold for molding. The pouring speed, mold temperature, and cooling system are the key control points. The pouring speed should be appropriate to avoid air bubbles and uneven distribution. The mold temperature is usually pre - heated to around 200°C - 300°C to ensure a smooth pouring process. The cooling system is designed to control the cooling rate, which affects the crystal growth and internal stress of the refractory material. A slow and uniform cooling rate can reduce internal stress and improve the overall performance of the product.

The oxidation process has a profound impact on the Na2O/K2O content and glass - phase structure. By reducing the Na2O/K2O content, the glass - phase structure becomes more stable. This stability significantly enhances the corrosion resistance and anti - crystallization ability of the refractory material. In glass kilns, these properties are crucial for long - term operation. For example, in a large - scale glass kiln, the service life of fused AZS refractory materials with optimized glass - phase structure can be extended by 20% - 30% compared with ordinary refractory materials.

Fused AZS refractory materials have excellent performance in glass kilns. Their high corrosion resistance can effectively resist the erosion of molten glass, reducing the pollution of the glass liquid. Their anti - crystallization ability can prevent the formation of crystals on the surface of the refractory material, ensuring the smooth operation of the kiln. In addition, their high - temperature stability can withstand the harsh environment of high - temperature kilns, providing reliable support for the production of high - quality glass products.

Based on more than 30 years of production and market experience, the optimized fused AZS refractory materials offer significant advantages in terms of performance and quality. Whether you are an engineering technician looking for high - performance refractory materials or a procurement decision - maker aiming to reduce costs and improve efficiency, these materials can meet your needs. To learn more about the technical details and application cases of our fused AZS refractory materials, please visit our official website's technical column.