In the glass manufacturing industry, the performance and durability of refractory materials directly impact production efficiency, product quality, and operational cost. Among these materials, AZS33 electric fused blocks have emerged as a reliable solution for critical components in glass melting furnaces. This article presents real-world application cases that highlight the material's unique properties and its value in enhancing furnace performance.

AZS33 is composed of high-purity alumina powder and zircon sand (containing 65% ZrO₂ and 34% SiO₂). The combination of these raw materials results in a dense microstructure with exceptional resistance to molten glass corrosion. This structure ensures long-term stability even under extreme thermal and chemical conditions commonly found in glass melting environments.

Testing data from laboratory analysis show that AZS33 has a porosity level below 1.5%, which significantly reduces the risk of glass liquid penetration and subsequent degradation. Compared to traditional refractories, AZS33 demonstrates a 30% higher resistance to alkali attack and a 20% improvement in thermal shock resistance.

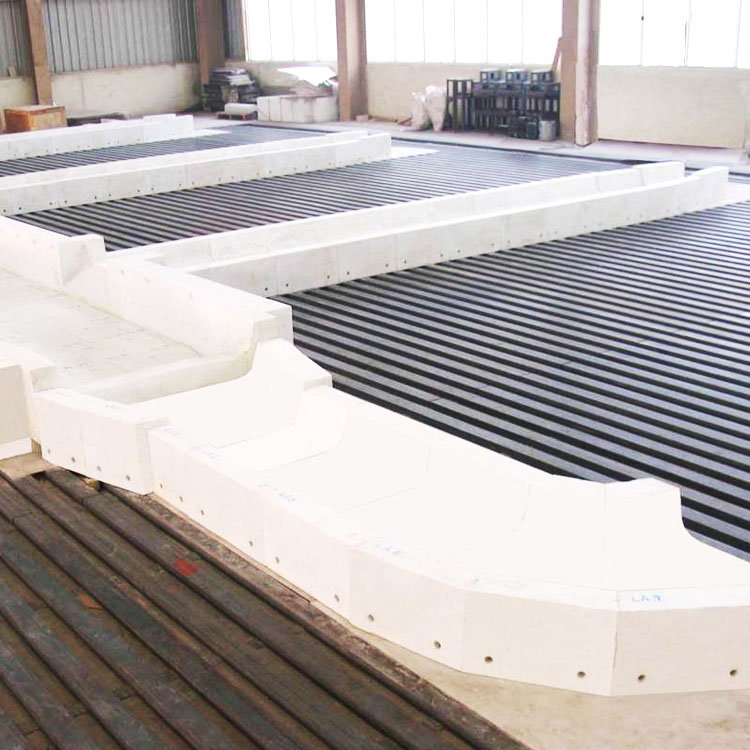

.jpg)

Several global glass manufacturers have successfully implemented AZS33 in their melting furnaces, achieving remarkable improvements in operational efficiency and product consistency.

A major flat glass producer in Europe replaced conventional refractories with AZS33 in the upper structure of its melting furnace. After six months of operation, the company reported a 25% reduction in maintenance frequency and a 15% increase in furnace uptime. The dense microstructure of AZS33 effectively resisted glass liquid erosion, maintaining structural integrity over extended periods.

A glass container manufacturer in Asia installed AZS33 blocks in the working pool side walls of its furnace. Data collected over one year showed a 40% decrease in refractory wear compared to previous materials. The improved corrosion resistance led to fewer production interruptions and a more stable melting process.

In another case, a glass fiber producer used AZS33 in the feeding channel area, where the material is exposed to intense thermal gradients and chemical attacks. The results were impressive—no signs of cracking or spalling were observed after 12 months of continuous operation. The furnace’s energy consumption also dropped by 10%, indicating better thermal efficiency.

| Parameter | AZS33 | Traditional Refractories |

|---|---|---|

| Porosity (%) | 1.2 | 3.5 |

| Thermal Shock Resistance | High | Medium |

| Alkali Attack Resistance | Excellent | Good |

AZS33 electric fused blocks are not just a material—they are a strategic investment in the longevity and efficiency of your glass production line. With proven performance in multiple applications, this advanced refractory solution offers unmatched reliability and cost-effectiveness.