Fused AZS (alumina-zirconia-silica) cast blocks are key refractory materials in the glass melting furnace industry. Composed of approximately 33% - 41% Al₂O₃, 15% - 30% ZrO₂, and the rest being SiO₂, these blocks possess a dense structure. Their density can reach up to 3.6 - 3.8 g/cm³, which is significantly higher than many other refractory materials. This dense structure endows them with excellent resistance to chemical corrosion and high - temperature erosion. The melting point of fused AZS blocks can exceed 1700°C, enabling them to maintain stable performance in extremely high - temperature environments.

Glass melting furnaces have different temperature zones. Generally, the temperature in the melting zone can reach 1500 - 1600°C, while the working end temperature is around 1200 - 1300°C. The temperature distribution has a crucial impact on the arrangement of refractory materials. In high - temperature areas, refractory materials need to have high melting points and good thermal shock resistance. If the wrong refractory material is placed in a high - temperature area, it may cause problems such as melting, cracking, and reduced service life. For example, in the melting zone, using materials with insufficient high - temperature resistance may lead to the formation of hot spots, which can accelerate the corrosion of the furnace lining and even cause safety hazards.

Based on the temperature distribution of the glass melting furnace, the layout of AZS blocks can be optimized. In the high - temperature melting zone, AZS blocks with high ZrO₂ content should be used. These blocks have better high - temperature stability and can effectively resist the erosion of molten glass. In the relatively low - temperature working end, AZS blocks with relatively lower ZrO₂ content can be used to reduce costs while still meeting the performance requirements.

In a practical case of a glass manufacturing plant, by analyzing the temperature distribution of the melting furnace, the engineers found that the original layout of AZS blocks was not reasonable. After re - arranging the AZS blocks according to the temperature zones, the service life of the furnace lining was extended by about 20%. The frequency of furnace shutdowns for maintenance was also reduced, which improved the production efficiency of the plant.

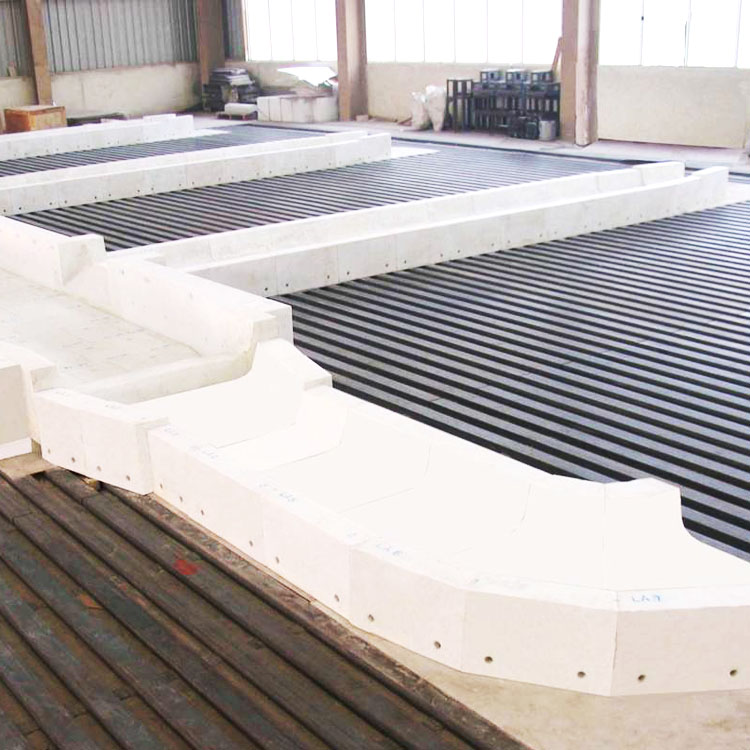

The installation of AZS blocks requires strict compliance with the process. First, the installation surface should be cleaned and leveled to ensure good contact between the blocks. Then, special refractory mortar should be used for bonding. During the installation process, the gap between the blocks should be controlled within 1 - 2 mm to ensure the overall stability of the furnace lining.

Common faults of AZS blocks include crystallization and thermal cracking. Crystallization is mainly caused by the long - term high - temperature environment and the presence of certain chemical substances in the molten glass. To prevent crystallization, the temperature and chemical composition of the molten glass should be strictly controlled. Thermal cracking is usually due to sudden temperature changes or uneven temperature distribution. To prevent thermal cracking, a reasonable heating and cooling curve should be established during the start - up and shutdown of the furnace. Regular inspection and maintenance of the furnace lining can also help to detect and solve problems in time, thereby extending the service life of the equipment.

If you want to learn more about the application technology of fused AZS blocks and optimize your glass melting furnace, click here for more in - depth information and technical support.