.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

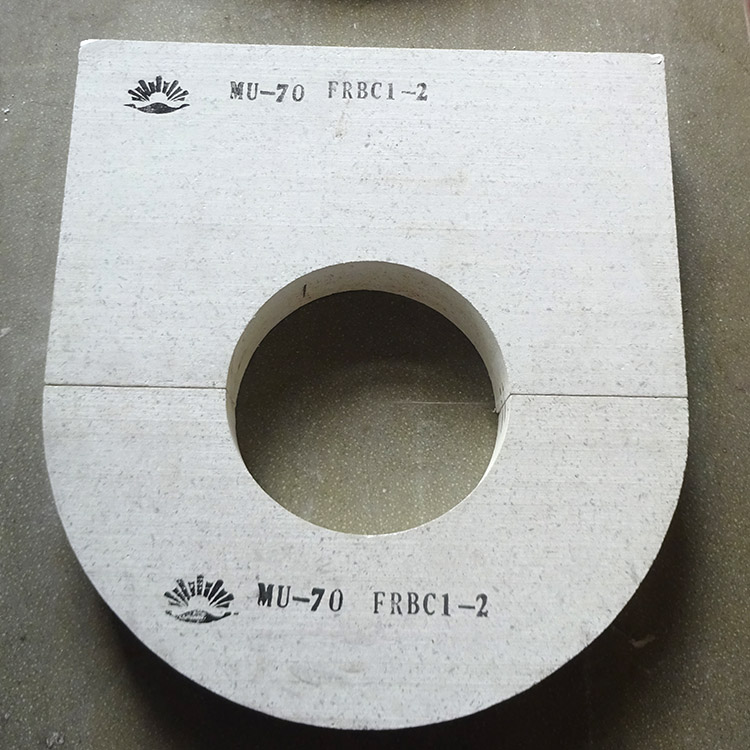

In the highly competitive global glass industry, the quality and efficiency of production are crucial for manufacturers to gain an edge. High - quality refractory materials play a pivotal role in achieving these goals. They not only ensure the smooth operation of glass furnaces but also directly impact the quality of the final glass products. Among various refractory materials, the AZS Type Rotary Tube Brick has emerged as a game - changer.

The AZS Type Rotary Tube Brick is renowned for its exceptional quality features. Firstly, it has a high refractoriness. It can withstand temperatures up to 1700°C without significant deformation. This high - temperature resistance ensures that the tube brick can maintain its structural integrity in the harsh environment of glass furnaces, where the molten glass can reach extremely high temperatures.

Secondly, its thermal stability is excellent. Tests have shown that it can endure rapid temperature changes of up to 1000°C without cracking. This is essential as glass production often involves heating and cooling cycles, and a material with poor thermal stability would quickly fail under such conditions.

Moreover, it has strong resistance to corrosion by molten glass. In a long - term immersion test in molten glass, the erosion rate of the AZS Type Rotary Tube Brick was found to be less than 0.1 mm per year, which is significantly lower compared to other common refractory materials. Its anti - peeling performance is also remarkable, which helps to maintain the smooth inner surface of the tube and prevent impurities from falling into the molten glass.

Our company holds ISO certification, which is a testament to our strict quality control processes. From raw material selection to the final product inspection, every step is carefully monitored. We use advanced production techniques, such as precision casting and high - temperature sintering, to ensure the consistent quality of the AZS Type Rotary Tube Brick. Our quality control team conducts multiple inspections at different production stages, including physical and chemical property tests, to guarantee that each tube brick meets the highest standards.

Many well - known glass manufacturers around the world have adopted our AZS Type Rotary Tube Brick and have witnessed significant improvements in their production processes. For example, a large - scale glass factory in Europe replaced their old refractory tubes with our AZS Type Rotary Tube Bricks. After six months of use, they reported a 20% increase in production efficiency due to reduced downtime for tube replacement and repairs. At the same time, the quality of their glass products improved, with a 15% reduction in defects caused by impurities from the refractory materials.

Another glass manufacturer in Asia also experienced similar benefits. They customized our AZS Type Rotary Tube Bricks according to their specific furnace design. The customized tubes fit perfectly into their production line, and they saw a notable reduction in glass liquid pollution, resulting in higher - quality glass products and increased customer satisfaction.

This product is the ideal choice for glass furnace feed tubes. With its excellent quality characteristics, ISO - certified production, and successful application cases, it can provide you with a reliable solution for your glass production. It allows you to make confident decisions that are beneficial to your production.

If you are interested in learning more about our AZS Type Rotary Tube Brick or have specific requirements for your glass production, please do not hesitate to contact us. Our professional team is ready to provide you with detailed information and customized solutions.

.jpg)

.jpg)