.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

In the glass manufacturing industry, producers often encounter a series of challenges that can affect the quality and efficiency of glass production. Issues such as glass solidification, uneven flow, and corrosion of equipment are common headaches. However, there is a revolutionary product that is changing the game - the AZS stir bar and stopper block.

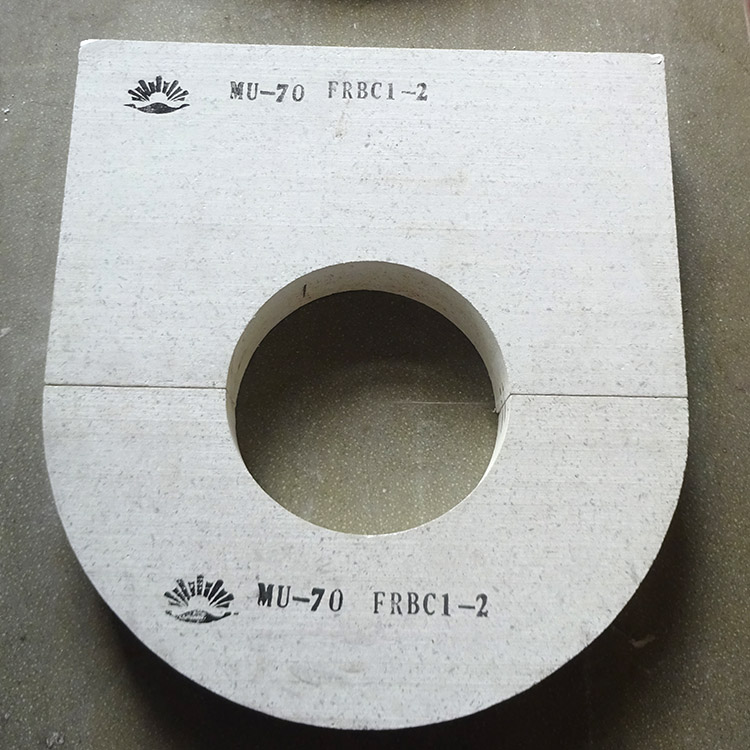

The AZS stir bar and stopper block are specifically designed for glass mixing. Let's delve into their remarkable properties:

These products can withstand extremely high temperatures. Tests have shown that they can maintain their structural integrity at temperatures up to 1700°C, which is well above the melting point of most glass types. This high - temperature resistance ensures stable performance during the glass - making process.

Thermal stability is crucial in glass production. The AZS stir bar exhibits excellent thermal shock resistance. In cyclic heating and cooling experiments, it can endure over 100 cycles between 1000°C and room temperature without significant cracking or damage, ensuring long - term use in fluctuating temperature environments.

It has strong anti - spalling performance. In practical applications, the spalling rate of the AZS stir bar is less than 5% after continuous use for 3 months, which is far lower than many traditional materials, reducing the risk of product contamination and equipment damage.

One of the key features of the AZS stir bar is its ability to prevent glass solidification and promote its flow. In a glass production line with a capacity of 500 tons per day, after using the AZS stir bar, the glass flow rate increased by 20%, effectively reducing the occurrence of solidification and blockage problems.

The AZS stir bar has low pollution levels. The impurity content released into the glass during the mixing process is less than 0.1%, ensuring the high - purity quality of the final glass product.

Let's look at a real - world example. A large - scale glass manufacturing company in Europe was facing issues with high solidification rates and low - quality glass products. After switching to the AZS stir bar, the defect rate of their glass products decreased from 8% to 2% within a month. Additionally, their production efficiency increased by 15%, resulting in significant cost savings.

.jpg)

When compared with other similar products on the market, the AZS stir bar stands out. Competitor products often have lower refractory temperatures, typically around 1500°C, and poorer thermal stability. In terms of anti - solidification performance, competitors may only achieve a 10% increase in glass flow rate, while the AZS stir bar can reach 20%. Also, the pollution levels of some competing products can be as high as 0.5%, which is five times that of the AZS stir bar.

In conclusion, the AZS stir bar and stopper block are indeed the quality saviors in glass production. Their outstanding properties, proven by real - world cases and comparative analysis, make them an ideal choice for glass manufacturers. If you are interested in learning more about these products, please contact our sales team at [Email Address] or visit our website [Website URL]. We also invite you to participate in our product demonstration to experience the amazing performance of the AZS stir bar firsthand.