.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

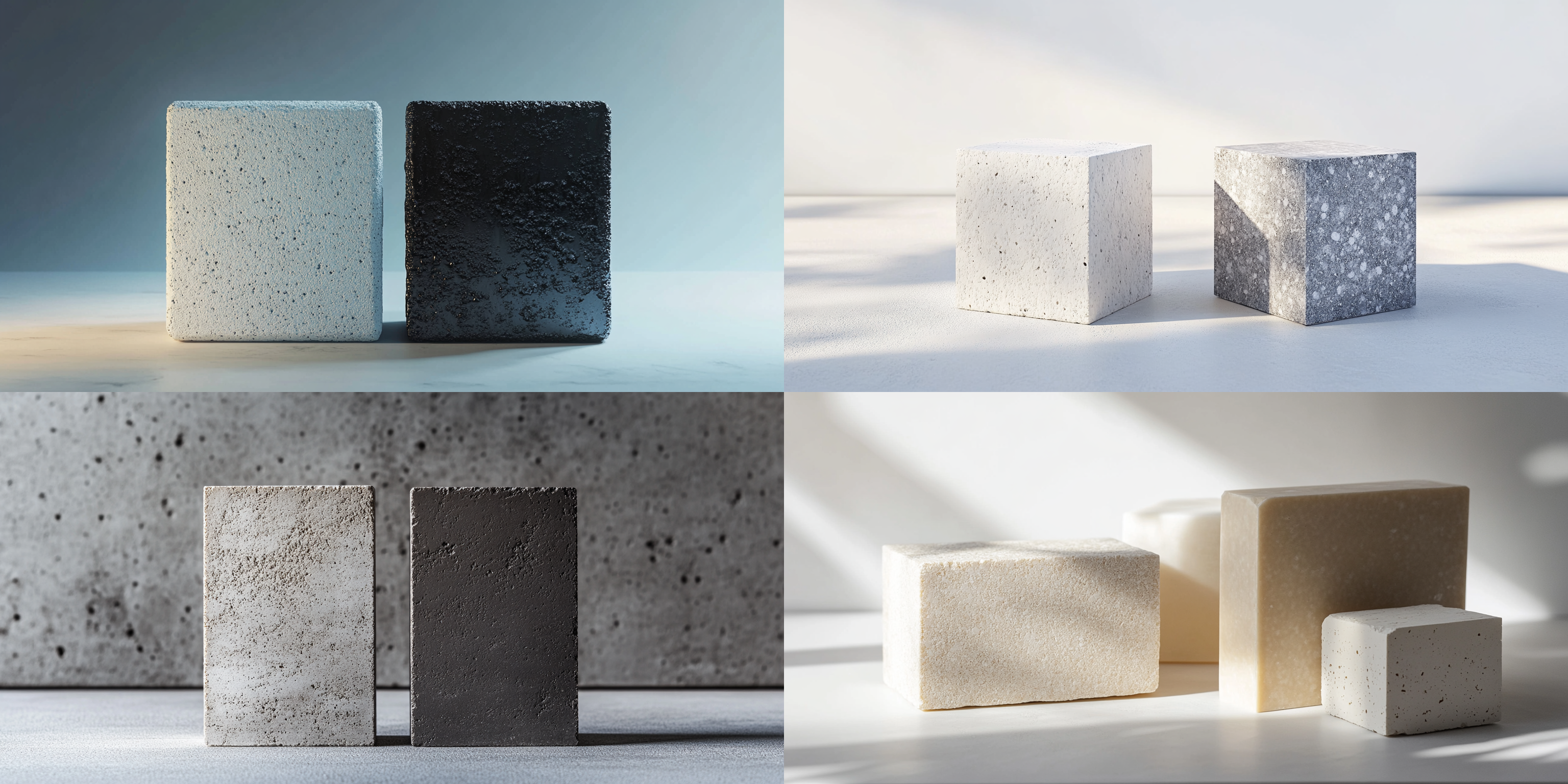

For glass manufacturers worldwide, durability and resistance to corrosive glass melts are critical parameters when selecting refractory materials for melting furnaces. AZS33, an advanced fused cast block, epitomizes innovation in this realm. Its unique scientific composition and microstructural excellence render it a frontrunner in sustaining performance under extreme thermal and chemical stresses.

AZS33’s primary constituents include high-purity alumina (Al2O3 powder), and a specialized zircon-containing quartz sand mixture composed of 65% zirconia (ZrO2) and 34% silica (SiO2). This carefully balanced recipe creates a microstructure characterized by an extraordinarily dense and homogenous matrix. The fusion-cast manufacturing process further enhances the compactness, minimizing open porosity — a critical factor that directly correlates with improved corrosion resistance.

.jpg)

When exposed to molten glass at temperatures often exceeding 1400°C, refractory components face chemical attacks primarily from alkalis and silica in the glass melt. AZS33’s dense microstructure minimizes the pathways through which these corrosive agents penetrate. The presence of zirconia in the quartz sand plays a pivotal role here; zirconia is known for its exceptional thermal stability and resistance to chemical dissolution. Together with alumina’s high melting point and mechanical strength, the resulting fused block withstands corrosion significantly better than traditional silica-based refractories.

| Material | Corrosion Rate (mm/year) | Porosity (%) |

|---|---|---|

| Traditional Silica Brick | 3.2 | 15 |

| Standard AZS Block | 1.1 | 5 |

| AZS33 Block | 0.7 | 3 |

The true test of refractory excellence is the performance in industrial settings. AZS33 blocks have been implemented across various high-temperature glass melting furnaces worldwide, particularly in regions demanding longer service life and enhanced furnace uptime. The dense structure and the chemical stability of AZS33 reduce corrosion depth, minimizing repairs and downtime. This boosts production continuity, reduces maintenance costs, and most importantly, ensures consistent glass quality by preventing contaminant infiltration.

A case study from a leading glass manufacturing plant reported a 35% increase in refractory service life after switching to AZS33 blocks in their glass contact zones, translating into tangible operational and economic benefits.

Global procurement managers, quality engineers, and industrial decision-makers face the challenge of balancing cost, performance, and reliability. AZS33 provides a scientifically validated solution, combining a superior raw materials formula and cutting-edge manufacturing processes. Its advantages include:

These features align AZS33 with the needs of enterprises seeking to optimize glass melting operations, reduce operational risks, and drive sustainable production growth.

AZS33 exhibits improved thermal shock resistance due to its optimized microstructure and higher zirconia content, reducing crack propagation risks under rapid temperature changes.

Yes, production technologies allow tailoring of AZS33 sizes and profiles to fit various furnace designs and customer requirements.

Its superior corrosion resistance reduces frequency and extent of repairs, resulting in lower downtime and maintenance labor.

Choosing AZS33 means investing in scientifically engineered durability and performance for glass production. Supported by data-driven insights and validated industrial successes, AZS33 refractories ensure your operations can meet the rigorous demands of modern glass melting. Solidify your supply chain with a trusted solution—enhance furnace longevity, improve product quality, and achieve measurable cost efficiencies.