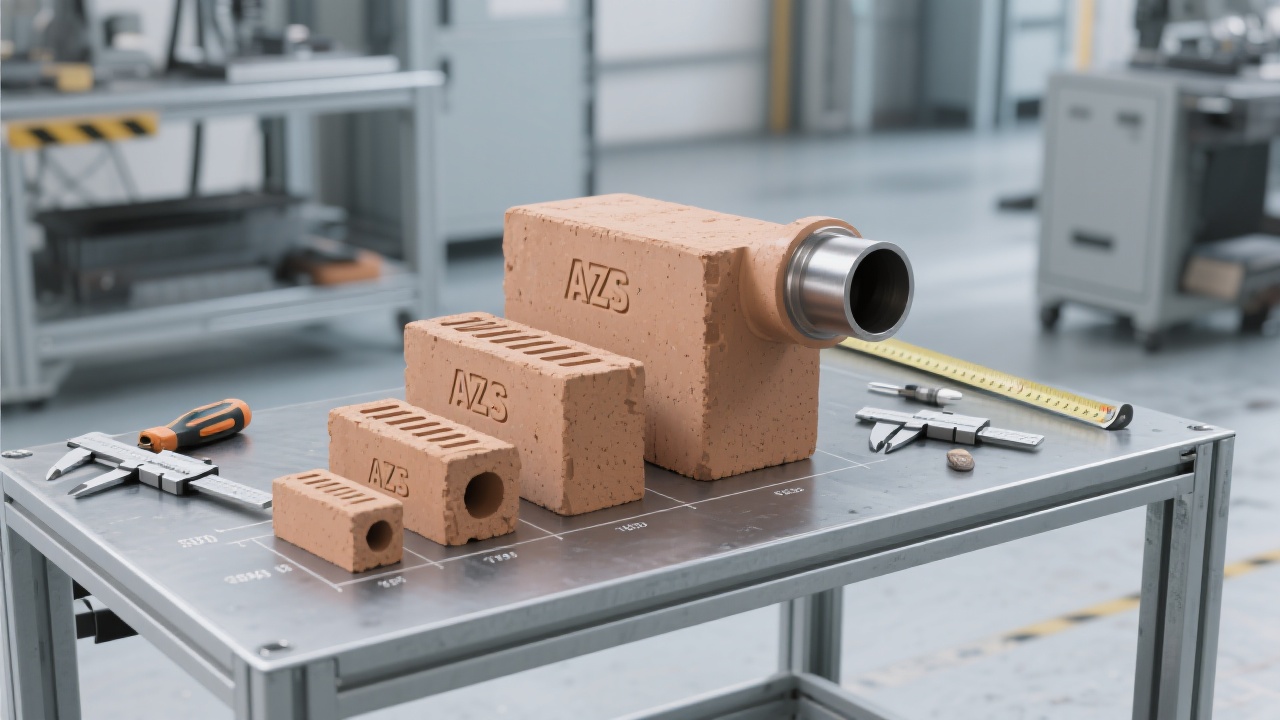

In the field of glass manufacturing, the lifespan and operational stability of glass furnace equipment are crucial factors affecting production efficiency and cost. Electro - fused AZS cast blocks have emerged as a game - changer due to their outstanding performance in high - temperature resistance, wear resistance, and corrosion resistance.

The unique composition of Al2O3 - ZrO2 - SiO2 in electro - fused AZS cast blocks and their dense micro - structure are the keys to their excellent performance. Alumina (Al2O3) provides high - temperature stability, zirconia (ZrO2) enhances wear resistance, and silica (SiO2) helps to form a protective layer. According to material science research, the high - purity Al2O3 content can reach up to 40 - 50% in high - quality electro - fused AZS cast blocks, which significantly improves the refractoriness of the material. The zirconia phase can increase the hardness of the material by about 30 - 40% compared to ordinary refractory materials, making it highly resistant to abrasion from molten glass and other particles.

In glass furnaces, electro - fused AZS cast blocks show remarkable performance in different parts. In the upper structure of the furnace, they can withstand high - temperature flue gases and prevent corrosion from alkaline substances. In the side walls, their wear - resistant properties protect against the erosion of flowing molten glass. In the charging channels, they resist the impact and abrasion of raw materials. For example, in a large - scale glass manufacturing plant, after replacing the traditional refractory materials with electro - fused AZS cast blocks in the side walls, the service life of the side walls was extended from 2 - 3 years to 5 - 6 years, which greatly reduced the frequency of equipment replacement and maintenance.

Let's take a look at some typical application scenarios. In a float glass production line, electro - fused AZS cast blocks are used in the melting zone. The high - temperature resistance and corrosion resistance of these blocks ensure the stable operation of the melting process. A real - world case shows that a glass factory reduced its production downtime by 20 - 30% after using electro - fused AZS cast blocks in the melting zone. Another example is in the production of optical glass. The high purity and stability of electro - fused AZS cast blocks prevent contamination of the glass, improving the quality of the final product.

Proper installation and maintenance are essential to maximize the performance of electro - fused AZS cast blocks. During installation, it is necessary to ensure a tight fit between the blocks to prevent the penetration of molten glass and gases. Regular inspections should be carried out to detect any signs of wear or damage. For example, checking the thickness of the blocks every 6 - 12 months can help to identify potential problems in time. If any damage is found, timely repair or replacement should be carried out to avoid further deterioration.

In conclusion, electro - fused AZS cast blocks are an ideal choice for glass furnace equipment, offering excellent wear and corrosion resistance, and effectively extending the service life of the equipment. By using these blocks, glass manufacturers can reduce operating costs, improve production efficiency, and ensure the stability of the production process. If you are looking for a reliable solution to enhance your glass furnace performance, click here to learn more about our electro - fused AZS cast blocks.