In the industrial sectors dealing with high-temperature processes, finding suitable refractory materials for high-temperature troughs is a persistent challenge. High temperatures can cause rapid degradation of common refractory materials, leading to frequent replacements, increased maintenance costs, and potential production disruptions. For example, in glass manufacturing, the temperature in the melting furnace can reach up to 1500°C, and traditional refractory materials may not withstand such extreme conditions for long.

AZS trough bricks are made of fused alumina zirconia silicate, a material specifically designed for high-temperature trough applications. This unique composition gives AZS trough bricks several advantages over other refractory materials.

Compared with silica bricks, which have a refractoriness under load of around 1650°C, AZS trough bricks can maintain their structural integrity at temperatures up to 1700°C. Their high corrosion resistance is also remarkable. In a chemical plant's high-temperature trough, while clay bricks may show signs of corrosion after 6 months of use, AZS trough bricks can last up to 2 years under the same conditions.

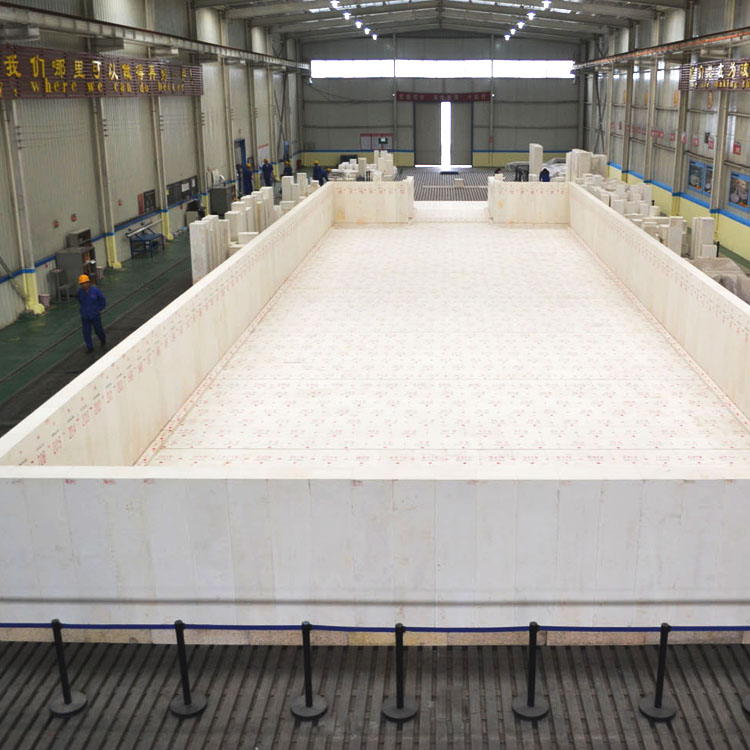

The manufacturing process of AZS trough bricks is a meticulous one that ensures high quality. First, high-purity raw materials, including alumina, zirconia, and silica, are carefully selected. These raw materials are then mixed in precise proportions. The mixture is melted in an electric furnace at a temperature of around 2000°C. Once fully melted, it is poured into molds and allowed to solidify slowly to form a ceramic bond.

This manufacturing process not only guarantees the density and uniformity of the bricks but also enhances their mechanical strength. Tests have shown that AZS trough bricks have a compressive strength of up to 300 MPa, which is much higher than many other refractory materials.

The use of high-purity raw materials is crucial for the quality of AZS trough bricks. High-purity alumina, with a purity of over 99%, provides excellent heat resistance, while high-purity zirconia enhances the corrosion resistance of the bricks. By using these top - grade raw materials, the performance and lifespan of AZS trough bricks are significantly improved.

Moreover, our AZS trough bricks have obtained ISO international certification. This certification is a testament to our strict quality control system, ensuring that every brick meets the highest international standards. It gives global buyers the confidence that they are purchasing a reliable and high - quality product.

AZS trough bricks have been widely used in various industries. In the glass industry, they are used in the melting furnaces and forehearths. A glass factory in Europe reported that after replacing traditional refractory materials with AZS trough bricks, the maintenance frequency of the furnace decreased by 60%, and the production efficiency increased by 20%.

In the metallurgical industry, AZS trough bricks are used in the troughs for transporting molten metals. Their high corrosion resistance and thermal stability prevent the erosion of the troughs, reducing the risk of leakage and improving the safety of the production process.

Our AZS trough bricks offer unparalleled performance and reliability. Don't miss out on this opportunity to enhance your production efficiency and reduce costs. Contact us today for more information and let our experts assist you in finding the perfect solution for your needs.

Contact Us Now