AZS (Alumina-Zirconia-Silica) channel blocks are essential components in high-temperature industrial applications, especially in electric arc furnaces and glass melting processes. As global demand for durable, high-performance refractory materials continues to rise, the need for reliable and advanced products like AZS channel blocks becomes more critical. This article explores the unique manufacturing process of AZS channel blocks, highlights their superior performance compared to other similar products, and explains why they are a preferred choice for industrial buyers worldwide.

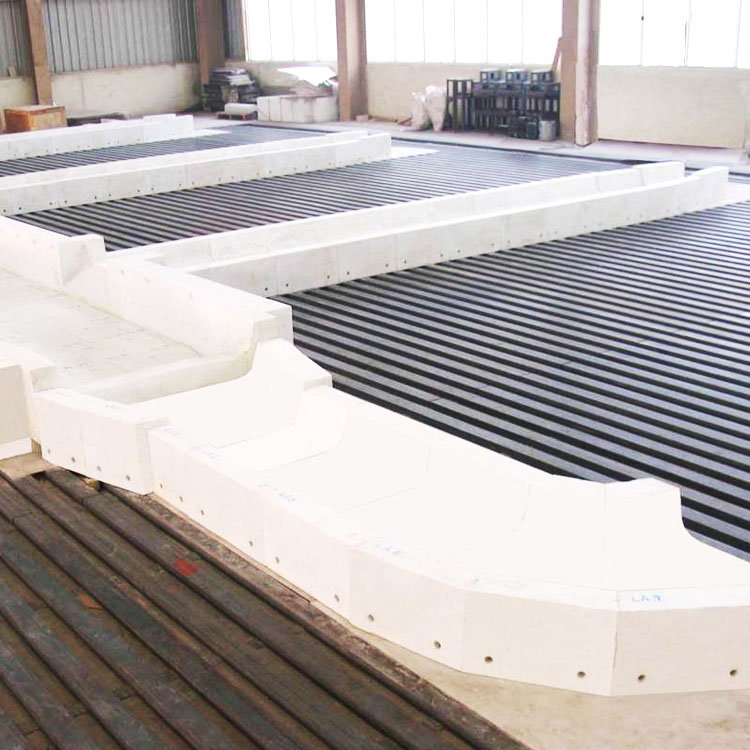

The production of AZS channel blocks involves several key steps that ensure their high performance under extreme conditions. First, raw materials such as high-purity alumina, zirconium oxide, and silica are carefully selected and blended according to precise formulas. These materials are then mixed in specialized equipment to ensure uniform distribution and optimal properties.

Next, the mixture is formed into blocks using high-pressure molding techniques. This step is crucial as it determines the structural integrity and density of the final product. After molding, the blocks undergo a controlled sintering process at temperatures exceeding 1600°C, which enhances their mechanical strength and thermal stability.

Several factors contribute to the superior quality of AZS channel blocks:

All AZS channel blocks produced by our company are manufactured under strict ISO 9001 quality management standards. This certification guarantees that every stage of production—from material selection to final inspection—is meticulously controlled to meet international quality benchmarks. It also demonstrates our commitment to delivering safe, reliable, and high-quality products that meet the expectations of global customers.

.jpg)

Compared to traditional refractory products such as magnesia-chrome bricks, AZS channel blocks offer significant advantages:

| Feature | AZS Channel Blocks | Traditional Magnesia-Chrome Bricks |

|---|---|---|

| Thermal Shock Resistance | Excellent | Moderate |

| Chemical Stability | High | Limited |

| Operating Temperature Range | Up to 1800°C | Up to 1600°C |

| Service Life | Longer | Shorter |

These advantages make AZS channel blocks particularly suitable for demanding environments where reliability and longevity are paramount.

In conclusion, the advanced manufacturing process of AZS channel blocks, combined with high-quality raw materials and rigorous quality control, sets them apart from other refractory products on the market. Whether you are looking to improve furnace efficiency, reduce maintenance costs, or enhance operational safety, AZS channel blocks provide a reliable solution that delivers long-term value.

For more information about our AZS channel blocks or to request a customized quote, please visit our official website. Our team is ready to support your business with expert advice and tailored solutions.