In high-temperature glass production environments—especially in float glass and bottle kilns—refractory materials must withstand extreme thermal stress, chemical attack, and mechanical wear for extended periods. Among these, electrofused AZS (Alumina-Zirconia-Silica) bricks have become the preferred choice for top-tier manufacturers worldwide. But what sets them apart from conventional fused or castables? The answer lies not just in raw material purity, but in a meticulously controlled manufacturing process that directly impacts performance longevity.

Traditional AZS bricks often contain residual alkali oxides (Na₂O + K₂O) above 0.7%, which significantly reduce their resistance to molten glass corrosion. In contrast, our proprietary electrofusion process achieves a consistent Na₂O + K₂O content of ≤ 0.3%, as validated by independent lab tests across 30+ industrial installations. This is made possible through precise oxidation control during melting at temperatures exceeding 1800°C—ensuring minimal alkali volatilization while maintaining structural integrity.

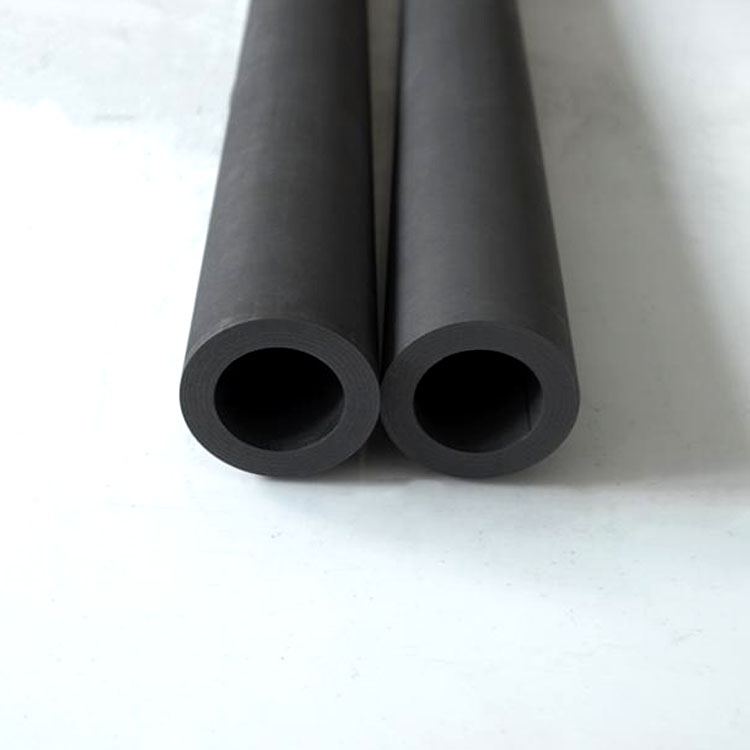

The journey begins with ultra-pure alumina (≥99.5%), zircon sand (ZrSiO₄), and silica sources carefully blended in stoichiometric ratios. Unlike traditional fusion methods, electrofusion uses direct current in an electric arc furnace, enabling full liquid-phase homogenization without contamination from crucible linings. This results in:

Real-world Performance Snapshot: TY-AZS36D installed in a 12m-wide float glass furnace operated continuously for 18 months without visible erosion at the crown or side walls—outperforming standard fused AZS by over 40% in service life.

These bricks are ideal for critical zones such as:

Engineers report fewer maintenance interruptions, reduced refractory replacement costs, and improved energy efficiency due to better heat retention—a win-win for both operations and sustainability goals.

For technical teams evaluating new refractory solutions—or procurement managers seeking long-term ROI—understanding this technology isn’t optional anymore. It’s essential.

Explore real case studies, technical specs, and application guides tailored to your specific glass production needs.

Discover More About Our Electrofused AZS Solutions